MULTIPLE FUEL INJECTION CONTROL OPERATION [WL-C, WE-C]

id0140b7738500

Function

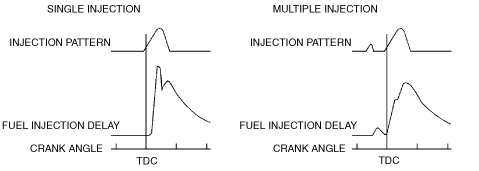

• In single injection, ignition delay becomes longer and much fuel is injected before ignition since the ignition has started. Therefore, the fuel is combusted rapidly at a high temperature and a high pressure, resulting in increased noise and NOx.

• To prevent this, the PCM performs multiple fuel injection. Due to this, the fuel is combusted slowly and the occurrence of noise and NOx is suppressed.

Operation

• Injection patterns of the multistage injection control according to the combination of injection times are shown in the figure. The PCM selects the optimum injection pattern based on the vehicle conditions and performs injection for 3 times at maximum.

• While in a driving condition at low engine speed and low engine load, the fuel injection time is increased up to 3 times to reduce knocking noise which occurs during combustion.

• While in a driving condition at high engine speed and high engine load, the fuel injection time is reduced to one time at minimum to improve output and fuel economy.

Operation condition

-

• The PCM determines the number of times fuel injection occurs based on the engine speed, fuel injection amount, and signals from each sensor.

• When the engine is started, the PCM calculates the number of times fuel injection occurs based on the engine coolant temperature, engine speed and fuel injection amount.