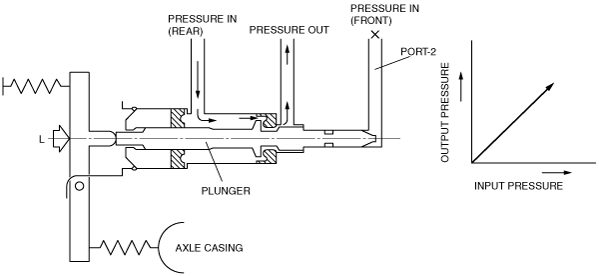

LOAD SENSING PROPORTIONING VALVE (LSPV) OPERATION

id041100101300

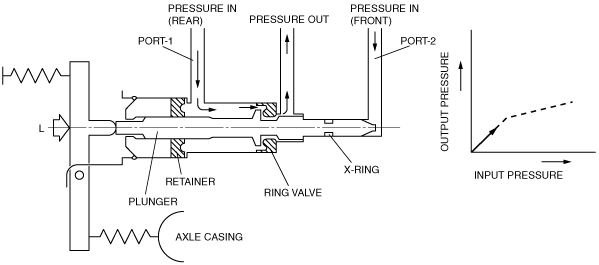

Braking When Vehicle Empty

• The hydraulic pressure generated at the rear section of the master cylinder is applied, via input port 1, to the hydraulic-pressure control section of the LSPV.

The hydraulic pressure generated at the front section of the master cylinder is applied to the front brakes, and to the bypass section of the LSPV via input port 2. The rear wheel and front wheel hydraulic pressure are separated by the X-ring of the plunger. Since port 1 hydraulic pressure is normally equal to port 2 hydraulic pressure, the plunger is pressed against the cylinder base by L.

When port 1 hydraulic pressure is applied to the plunger, the plunger tries to move to the left. But, because there is also at the same time force applied in the right direction by the lever link (force L), the plunger is held against the cylinder base. The result is that the hydraulic pressure at the output side is the same as at the input side when force L is higher than the input pressure.

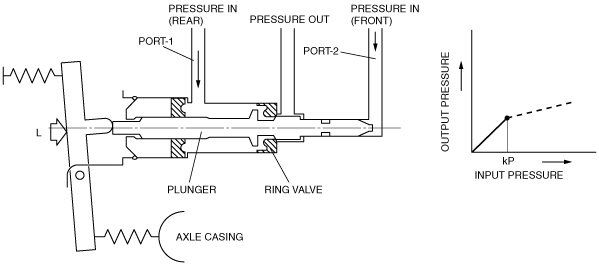

• When the input hydraulic pressure increases further and overcomes force L, the plunger is moved slightly leftward, sealing it against the ring valve. This temporarily separates the input side from the output side. The output pressure at this time is called the break point. If force L from the lever link changes (i.e. lowering of the vehicle body), this break point changes accordingly.

• When the input pressure passes the break point, the plunger is moved back against the cylinder base. The output port is opened, and hydraulic pressure generated at the rear section of the master cylinder is applied to the rear wheel cylinders.

As the output pressure continues to increase, the plunger is again moved toward the left against the ring valve, thus separating the input and output side again.

This action is repeated to control the output pressure.

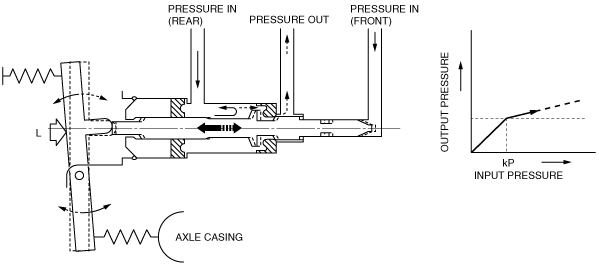

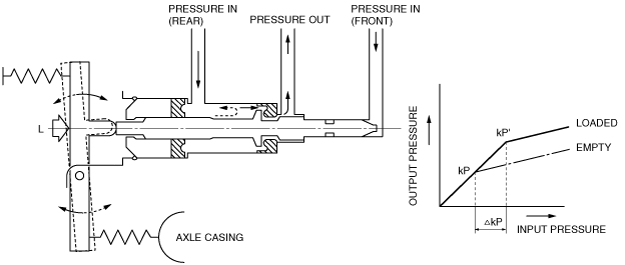

Braking When Vehicle Loaded

• The vehicle height (from the ground) decreases when cargo is loaded into the vehicle. This causes the force of the spring connected to the axle casing to decrease and the force of the spring on the LSPV to increase force L, increasing the pressure holding the plunger to the right.

The master cylinder hydraulic pressure (input) needed to cause the plunger to move back to the left also becomes equally higher as a result.

This causes the break point to be increased and extra barking power is provided in accordance with the weight of cargo loaded.

If Malfunction Of Front Hydraulic System

• If there is a malfunction of the front-brake hydraulic system, the hydraulic pressure from input port 2 becomes zero. The result is that the input pressure presses the plunger to the right, opening the bypass passage.

The output pressure thus equals the input pressure, and there is so pressure reduction.