|

CONTROL VALVE BODY INSTALLATION [5R55S]

id0513c1710700

On-Vehicle Installation

1. Install the control valve body and loosely install the bolts.

b5r5za00000268

|

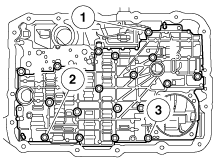

2. Tighten the bolts in the sequence shown.

b5r5za00000270

|

3. Install the detent spring.

b5r5za00000271

|

4. Install new O-rings on the solenoid body connector. Lubricate the O-rings with clean ATF.

b5r5za00000272

|

5. Install the solenoid body. Tighten bolts in the sequence shown.

b5r5za00000273

|

6. Install the reverse servo. Tighten the bolts in the sequence shown in 2 stages.

b5r5za00000274

|

7. Lubricate the seals and install the transmission fluid filter.

b5r5za00000275

|

8. Install the transmission fluid pan gasket on the pan.

absggw00001562

|

9. Install the transmission fluid pump and gasket, magnet and loosely install the bolts.

b5r5za00000276

|

10. Tighten the bolts in a crisscross sequence.

11. Install and lubricate new O-rings on the AT connector and connect the connector.

absggw00001183

|

12. Remove the insulator bracket. (See AUTOMATIC TRANSMISSION REMOVAL/INSTALLATION [5R55S].)

13. Remove the CKP sensor insulator. (See AUTOMATIC TRANSMISSION REMOVAL/INSTALLATION [5R55S].)

14. Remove the digital TR sensor insulator. (See AUTOMATIC TRANSMISSION REMOVAL/INSTALLATION [5R55S].)

15. Connect the negative battery cable.

16. Add ATF and, with the engine idling, inspect the ATF level and for leakage. (See AUTOMATIC TRANSMISSION FLUID (ATF) INSPECTION [5R55S].)

17. Perform the mechanical system test. (See MECHANICAL SYSTEM TEST [5R55S].)

18. Perform the road test. (See ROAD TEST [5R55S].)