CYLINDER BLOCK INSPECTION/REPAIR [WLT-1, WLT-2, WL-3]

id011097501800

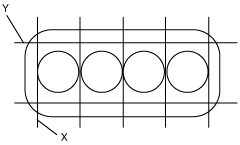

1. Measure the distortion of the cylinder block top surface in the seven directions as shown in the figure.

-

• If the distortion exceeds the maximum specification, replace the cylinder head.

-

Maximum cylinder block distortion

-

X direction: 0.02 mm {0.0008 in}

Y direction: 0.05 mm {0.0020 in}

2. Measure the cylinder bore using the cylinder gauge. Measurement positions are in the X and Y directions at 83 mm {3.27 in} below the top surface of the cylinder.

-

• If the cylinder bore exceeds the wear limit, replace the cylinder block or rebore the cylinder and install the oversized pistons so that the specified piston-to-cylinder clearance is obtained.

-

Note

-

• Base the boring diameter on the diameter of an oversized piston. All cylinders must be the same diameter.

-

Cylinder bore size

-

Standard: 93.000—93.022 mm {3.6615—3.6622 in}

0.25 {0.01} oversize: 93.250—93.272 mm {3.6713—3.6721 in}

0.50 {0.02} oversize: 93.500—93.522 mm {3.6811—3.6819 in}

-

Cylinder bore wear limit

-

0.15 mm {0.0059 in}