|

bwl1ge00000076

CRANKSHAFT INSPECTION [WLT-1, WLT-2, WL-3]

id011097502500

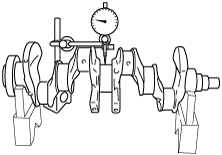

1. Measure the crankshaft runout.

bwl1ge00000076

|

2. Measure the main journal or crank pin diameter in the X and Y directions at the two points (A and B) as shown in the figure.

bwl1ge00000077

|