CONNECTING ROD OIL CLEARANCE INSPECTION/REPAIR [WLT-1, WLT-2, WL-3]

id011097502900

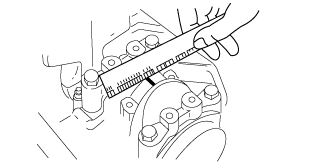

1. Position a plastigage on top of the journals in the axial direction.

2. Install the connecting rod cap. (See CYLINDER BLOCK ASSEMBLY (I) [WLT-1, WLT-2, WL-3].)

3. Remove the connecting rod cap.

4. Measure the crankpin oil clearance.

-

• If the clearance exceeds the maximum, replace the connecting rod bearing or grind the crankpin and use undersized bearings so that the specified clearance is obtained.

-

Standard connecting rod oil clearance

-

0.025—0.052 mm {0.0010—0.0020 in}

-

Maximum connecting rod oil clearance

-

0.08 mm {0.0031 in}

-

Connecting rod bearing thickness

-

Standard: 1.507—1.516 mm {0.0594—0.0596 in}

0.25 {0.01} undersize: 1.624—1.634 mm {0.0640—0.0643 in}

0.50 {0.02} undersize: 1.749—1.759 mm {0.0689—0.0692 in}

0.75 {0.03} undersize: 1.874—1.884 mm {0.0738—0.0741 in}