|

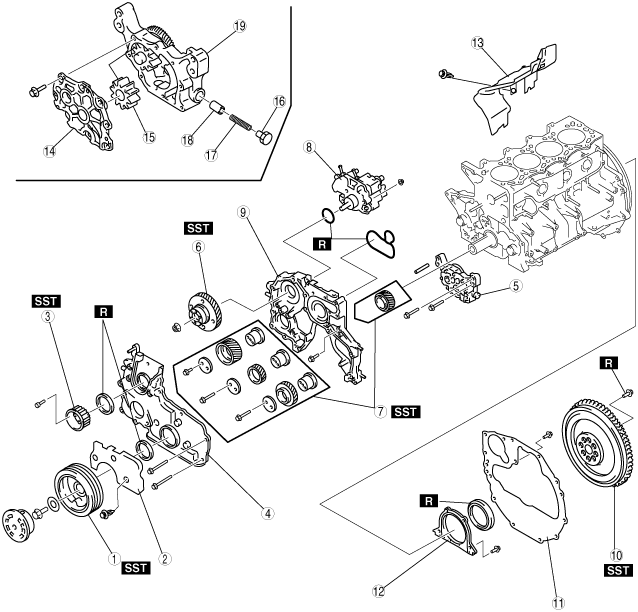

CYLINDER BLOCK DISASSEMBLY (II) [WL-C, WE-C]

id0110b6500700

1. Disassemble in the order shown in the figure.

bwl1ge00000213

|

|

1

|

Crankshaft pulley

|

|

2

|

Seal plate

|

|

3

|

Supply pump pulley

|

|

4

|

Timing gear cover

|

|

5

|

Oil pump

|

|

6

|

Supply pump gear

|

|

7

|

Timing gear

|

|

8

|

Supply pump

|

|

9

|

Timing gear case

|

|

10

|

Dual-mass flywheel

|

|

11

|

End plate

|

|

12

|

Rear cover

(See Rear Cover Disassembly Note.)

|

|

13

|

Seal plate

|

|

14

|

Oil pump cover

|

|

15

|

Driven gear

|

|

16

|

Plug

|

|

17

|

Plunger spring

|

|

18

|

Control plunger

|

|

19

|

Oil pump body

|

Crankshaft Pulley Disassembly Note

1. Remove the crankshaft pulley using the SST.

bwl1ge00000214

|

Supply Pump Pulley Disassembly Note

1. Remove the supply pump pulley using the SST.

bwl1ge00000215

|

Timing Gear Cover Disassembly Note

1. Remove the timing gear cover using a separator tool.

bwl1ge00000216

|

2. Remove the oil seal using a screwdriver protected with a rag,

bwl1ge00000217

|

Supply Pump Gear Disassembly Note

1. Set the No.1 cylinder to TDC of compression.

2. Rotate the flywheel ring gear from TDC to approximately 30° BTDC (about 13 teeth on the gear).

bwl1ge00000218

|

3. Verify that the end-gap (V groove) of the timing gear case and the chip cut gear of the fuel injection pump gear are aligned.

bwl1ge00000219

|

4. Fix the scissors gear to the supply pump gear using a lock bolt (M6×1.0; length under the bolt head is approximately 16 mm {0.63 in}).

bwl1ge00000220

|

5. Hold the crankshaft using the SST and loosen the gear nut.

bwl1ge00000221

|

6. Remove the supply pump gear using the SST and bolt (M6X1.0, Length 30mm {1.18 in}).

bwl1ge00000222

|

Timing Gear Case Disassembly Note

1. Remove the timing gear case using the separator tool.

bwl1ge00000223

|

Dual-mass flywheel Disassembly Note

1. Lock the dual-mass flywheel against rotation using the SST (49 E011 1A0).

2. Loosen the lock bolts uniformly and gradually in the order shown in the figure, and remove them.

bwl1ge00000224

|

bwl1ge00000225

|

bwl1ge00000226

|

3. Remove the dual-mass flywheel.

4. Remove the SST.

Rear Cover Disassembly Note

1. Remove the oil seal using a screwdriver protected with a rag.

bwl1ge00000227

|