|

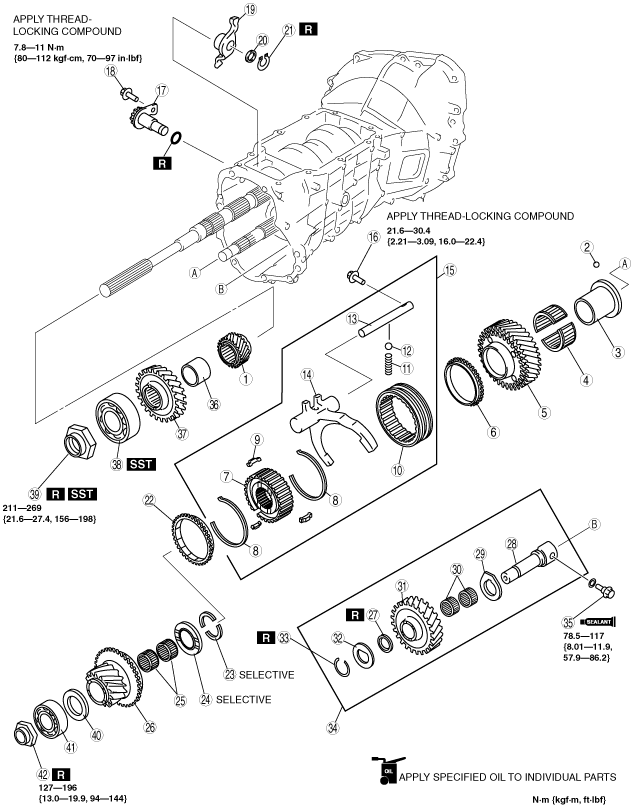

5TH/REVERSE GEAR COMPONENT ASSEMBLY

id051100520600

1. Assemble in the order indicated in the table.

bms1zm00000235

|

|

1

|

5th counter gear

|

|

2

|

Steel ball

|

|

3

|

5th gear bearing inner race

|

|

4

|

Needle bearing

|

|

5

|

5th gear

|

|

6

|

Synchronizer ring

|

|

7

|

5th/reverse clutch hub

|

|

8

|

Synchronizer key spring

|

|

9

|

Synchronizer key

|

|

10

|

Clutch hub sleeve

|

|

11

|

Detent spring

|

|

12

|

Detent ball

|

|

13

|

5th/reverse shift rod

|

|

14

|

5th/reverse shift fork

|

|

15

|

5th/reverse clutch hub and shift fork component

|

|

16

|

Retaining bolt

|

|

17

|

Counter lever shaft component

|

|

18

|

Retaining bolt

|

|

19

|

Counter lever

|

|

20

|

Washer

|

|

21

|

Retaining ring

|

|

22

|

Thrust washer

|

|

23

|

Thrust washer

|

|

24

|

Spacer

|

|

25

|

Needle bearing

|

|

26

|

Reverse gear

(See Reverse Gear Assembly Note.)

|

|

27

|

Friction damper

|

|

28

|

Reverse idler gear shaft

|

|

29

|

Thrust washer

|

|

30

|

Needle bearing

|

|

31

|

Reverse idler gear

|

|

32

|

Thrust washer

|

|

33

|

Retaining ring

|

|

34

|

Reverse idler gear shaft component

|

|

35

|

Retaining bolt

|

|

36

|

Spacer

|

|

37

|

Reverse counter gear

|

|

38

|

Mainshaft rear bearing

|

|

39

|

Locknut

|

|

40

|

Thrust washer

|

|

41

|

Countershaft rear bearing

|

|

42

|

Locknut

|

5th Gear Bearing Inner Race Assembly Note

1. Install the steel ball to the countershaft.

bms1zm00000147

|

2. Align the ball groove position of the 5th gear bearing inner race and assemble it to the countershaft.

5th Counter Gear, 5th/Reverse Clutch Hub Component and 5th/Reverse Shift Fork Assembly Note

1. Assemble the 5th drive gear and 5th/reverse clutch hub component.

bms1zm00000148

|

|

|

A |

B |

C |

|---|---|---|---|

|

5th/6th

|

18.0 {0.709}

|

5.45 {0.215}

|

6.0 {0.236}

|

bms1zm00000149

|

2. Assemble the 5th counter gear component, 5th/reverse clutch hub component, and 5th/reverse shift fork component as a single unit.

bms1zm00000150

|

3. Install the 5th/reverse shift rod retaining bolt.

bms1zm00000151

|

4. Install the thrust washer.

5. Measure the clearance between thrust washer and groove of the countershaft.

bms1zm00000152

|

5th/Reverse clutch hub thrust washer

|

Thickness (mm {in}) |

|---|

|

3.00 {0.118}

|

|

3.05 {0.120}

|

|

3.10 {0.122}

|

|

3.15 {0.124}

|

|

3.20 {0.126}

|

|

3.25 {0.128}

|

|

3.30 {0.130}

|

|

3.35 {0.132}

|

|

3.40 {0.134}

|

Reverse Gear Assembly Note

1. Measure the clearance A and B.

bms1zm00000153

|

Reverse gear spacer

|

Dimension C (mm {in}) |

Thickness (mm {in}) |

|---|---|

|

7.60—7.70

{0.300—0.303}

|

7.35 {0.289}

|

|

7.70—7.80

{0.304—0.307}

|

7.45 {0.293}

|

|

7.80—7.90

{0.308—0.311}

|

7.55 {0.297}

|

|

7.90—8.00

{0.312—0.314}

|

7.65 {0.301}

|

|

8.00—8.10

{0.315—0.318}

|

7.75 {0.305}

|

2. Install the spacer.

3. Install the reverse gear.

Counter Lever Shaft Assembly Note

1. Install the counter lever shaft component.

bms1zm00000154

|

Reverse Idler Gear Component Assembly Note

1. Using the SSTs, install the friction damper to the reverse idler gear.

bms1zm00000155

|

bms1zm00000156

|

2. Assemble the reverse idler gear component.

3. Measure the clearance between the retaining ring and thrust washer.

bms1zm00000157

|

Reverse idler gear retaining ring

|

Thickness (mm {in}) |

|---|

|

1.5 {0.059}

|

|

1.6 {0.063}

|

|

1.7 {0.067}

|

|

1.8 {0.071}

|

|

1.9{0.075}

|

4. Install the reverse idler gear component to the transmission case.

bms1zm00000158

|

5. Install the reverse idler gear shaft retaining bolt.

bms1zm00000159

|

Mainshaft Rear Bearing and Countershaft Rear Bearing Locknut Assembly Note

1. Slide the 3rd/4th and 1st/2nd clutch hub sleeves to lock the transmission into 4th and 2nd gears.

bms1zm00000160

|

2. Insert the mainshaft rear bearing into the mainshaft and install the locknut.

3. Attach the SST to the locknut and tighten the nut to the specified torque.

bms1zm00000161

|

4. Tighten the countershaft locknut in the counterclockwise direction.

bms1zm00000162

|

5. Using the pin punch, stake the mainshaft rear bearing locknut.

bms1zm00000163

|

6. Using the pin punch, stake the countershaft rear bearing locknut.

bms1zm00000164

|