INTERMITTENT CONCERN TROUBLESHOOTING [WLT-1, WLT-2]

id010396800400

Vibration Method

• If a malfunction occurs or becomes worse while driving on a rough road or when the engine is vibrating, perform the steps below.

-

Note

-

• There are several reasons the vehicle or engine vibration could cause an electrical malfunction. Some of the things to check for are:

-

― Connectors not fully seated.

― Wiring harnesses not having full play.

― Wiring harnesses laying across brackets or moving parts.

― Wiring harnesses routed too close to hot parts.

• An improperly routed, improperly clamped, or loose wiring harness can cause the wiring harness to become pinched between parts.

• The connector joints, points of vibration, and places where the wiring harnesses pass through the fire wall, body panels, etc. are the major areas to be checked.

Inspection Method for Switch Connectors or Wiring Harnesses

1. Connect the M-MDS to the DLC.

2. Turn the engine switch to the ON position (Engine off).

-

Note

-

• If engine starts and runs, perform the following steps while idling the engine.

3. Access the PIDs for the switch you are inspecting.

4. Turn the switch on manually.

5. Shake each connector or wiring harness a bit vertically and horizontally while monitoring the PID.

-

• If the PID value is unstable, check for a poor connection.

Inspection Method for Sensor Connectors or Wiring Harness

1. Connect the M-MDS to the DLC.

2. Turn the engine switch to the ON position (Engine off).

-

Note

-

• If engine starts and runs, perform the following steps while idling the engine.

3. Access PIDs for the switch you are inspecting.

4. Shake each connector or wiring harness a bit vertically and horizontally while monitoring the PID.

-

• If the PID value is unstable, check for a poor connection.

Inspection Method for Sensors

1. Connect the M-MDS to the DLC.

2. Turn the engine switch to the ON position (Engine off).

-

Note

-

• If the engine starts and runs, perform the following steps while idling the engine.

3. Access the PIDs for the switch you are inspecting.

4. Vibrate the sensor slightly with your finger.

-

• If the PID value is unstable or a malfunction occurs, check for a poor connection and/or poorly mounted sensor.

Inspection Method for Actuators or Relays

1. Connect the M-MDS to the DLC.

2. Turn the engine switch to the ON position (Engine off).

-

Note

-

• If engine starts and runs, perform the following steps while idling the engine.

3. Prepare the SIMULATION TEST for actuators or relays that you are inspecting.

4. Vibrate the actuator or relay with your finger for 3 s after SIMULATION TEST is activated.

-

• If a variable click sound is heard, check for a poor connection and/or poorly mounted actuator or relay.

-

Note

-

• Vibrating the relays too strongly may result in open relays.

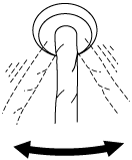

Water Sprinkling Method

• If the malfunction occurs only during high humidity or rainy/snowy weather, perform the following steps.

-

Caution

-

• Indirectly change the temperature and humidity by spraying water onto the front of the radiator.

• If a vehicle is subject to water leakage, the leakage may damage the control module. When testing a vehicle with a water leakage problem, special caution must be used.

1. Connect the M-MDS to the DLC if you are inspecting sensors or switches.

2. Turn the engine switch to the ON position (Engine off).

-

Note

-

• If the engine starts and runs, perform the following steps while idling the engine.

3. Access the PIDs for the sensor or switch if you are inspecting sensors or switches.

4. If you are inspecting the switch, turn it on manually.

5. Spray water onto the vehicle or run it through a car wash.

-

• If the PID value is unstable or a malfunction occurs, repair or replace part if necessary.