|

ENGINE CONTROL SYSTEM OPERATION INSPECTION [WLT-1, WLT-2]

id010396803700

FICD System Inspection

Fast-Idle Function

1. Verify that the FICD actuator rod is not pulled.

2. Verify that the engine is cold. (ECT is below 20 °C {68 °F})

3. Turn fan switch off.

4. Start the engine.

5. Verify that the FICD actuator rod is pulled.

absggw00000222

|

6. If not, disconnect the vacuum hoses from the FICD actuator and inspect if there is vacuum as shown.

absggw00000223

|

7. If there is vacuum, consult your distributor for replacement of the FICD actuator.

8. If there is no vacuum, inspect the following:

9. Warm up the engine. (ECT is above 20 °C {68 °F})

10. Verify that the FICD actuator rod returns for one notch.

absggw00000224

|

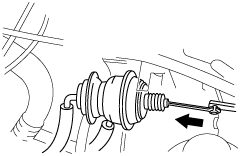

11. If not, disconnect vacuum hose A from the FICD actuator and inspect if there is vacuum.

absggw00000225

|

12. If there is no vacuum, consult your distributor for replacement of the FICD actuator.

13. If there is vacuum, inspect the following:

14. Warm up the engine. (ECT is above 60 °C {140 °F})

15. Verify that the FICD actuator rod returns completely.

absggw00000224

|

16. If not, disconnect vacuum hose B from the FICD actuator and inspect if there is vacuum.

absggw00000226

|

17. If there is no vacuum, consult your distributor for replacement of the FICD actuator.

18. If there is vacuum, inspect the following:

A/C Idle-up Function

1. Start the engine.

2. Warm up the engine to normal operating temperature and run it at idle speed.

3. Set the fan switch at 1st position.

4. Verify that the FICD rod is pulled for one notch.

5. If not, disconnect the vacuum hose B from the FICD actuator and inspect if there is vacuum as shown.

absggw00000226

|

6. If there is vacuum, consult your distributor for replacement of the FICD actuator.

7. If there is no vacuum, inspect the following:

Turbocharger Boost Pressure

1. Disconnect the air hose between the intake pipe and the boost compensator.

2. Connect a pressure gauge. (range of measurement is 93.3 kPa {700 mmHg, 27.6 inHg})

absggw00000227

|

3. Warm up the engine.

4. With the accelerator at the wide open throttle, increase the engine speed to 4,800—5,000 rpm and verify that the boost pressure is within the specification.

5. If not as specified, inspect the exhaust system.

6. If the exhaust system is normal, inspect the wastegate actuator.

7. If the wastegate actuator is normal, inspect the turbocharger.

TCV Control Inspection

1. Crank the engine and verify that the TCV operation sound is heard.

absggw00000228

|

2. If no operation sound is heard, inspect the TCV. (in the FIP)

3. If the TCV is normal, inspect the following:

EGR System Inspection (WLT-2)

1. Make sure that all hoses are securely connected in the proper position.

2. Disconnect the vacuum hose from the EGR valve.

3. Start the engine at cold condition.

4. Verify that there is no vacuum at vacuum hose.

5. If there is vacuum, inspect the following:

6. Warm up the engine to the normal operating temperature and run it at idle speed.

7. Verify that there is vacuum at vacuum hose.

8. If there is no vacuum, inspect the following:

9. Connect the vacuum pump to the EGR valve.

10. Apply the vacuum to the EGR valve and inspect if the engine speed becomes unstable or the engine stalls.

11. If the engine speed dose not change, stop the engine and inspect the EGR valve.