COMPRESSION INSPECTION [WLT-1, WLT-2]

id011096800300

-

Warning

-

• When the engine and the oil are hot, they can badly burn. Turn off the engine and wait until they are cool.

1. Verify that the battery is fully charged.

-

2. Warm up the engine to the normal operating temperature.

3. Stop the engine and allow it to cool down for about 10 minutes.

-

Warning

-

• Fuel line spills and leaks are dangerous. Fuel can ignite and cause serious injuries or death and damage. Fuel can also irritate skin and eyes. To prevent fuel from spurting out of the injection nozzle hole, do not ground the fuel cut solenoid valve terminal.

4. Disconnect the fuel cut solenoid valve connector.

5. Remove all the glow plugs. (See GLOW PLUG REMOVAL/INSTALLATION [WLT-1, WLT-2].)

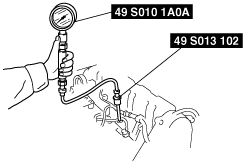

6. Install the SSTs into the glow plug hole.

7. Crank the engine and note the maximum gauge reading.

8. Check each cylinder as above.

-

Compression

-

Standard: 2,942 {30, 427}[200] (kPa {kgf/cm2, psi}[rpm])

Minimum: 2,648 {27, 384}[200] (kPa {kgf/cm2, psi}[rpm])

9. If the compression in one or more cylinders is low, pour a small amount of clean engine oil into the cylinder and recheck the compression.

- (1) If the compression increases, the piston, the piston rings, or cylinder wall may be worn and overhaul is required.

-

- (2) If the compression stays low, a valve may be stuck or improperly seated and overhaul is required.

-

- (3) If the compression in adjacent cylinders stays low, the cylinder head gasket may be damaged or the cylinder head distorted and overhaul is required.

-

10. Remove the SST.

11. Install the glow plug. (See GLOW PLUG REMOVAL/INSTALLATION [WLT-1, WLT-2].)

12. Connect the fuel cut solenoid valve connector.