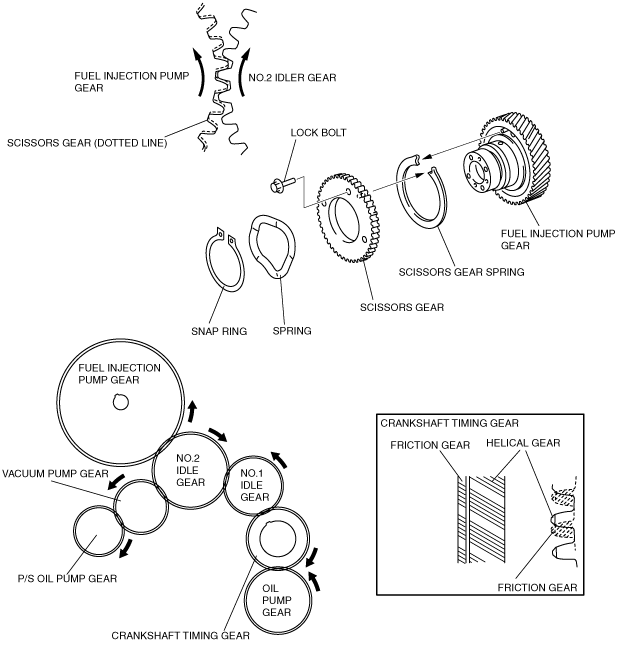

TIMING GEAR CONSTRUCTION [WL-3]

id0110b5103100

• A helical timing gear has been adopted.

• The friction gear is assembled to the crankshaft timing gear.

• The scissors gear is assembled to the fuel injection pump gear.

• The friction gear is assembled to the crankshaft timing gear to reduce the backlash between the oil pump gear and No. 1 idler gear, and to reduce tooth contact noise.

• The scissors gear, through the force of the scissors gear spring, prevents the teeth of the fuel injection pump gear from moving back and forth (backlash) between the teeth of the No.2 idler gear, with which the fuel injection pump gear is meshed, and thus reduces gear noise.

• When removing the fuel injection pump gear, fix the scissors gear to the fuel injection pump gear using a lock bolt (M8 x 1.25, length under the bolt head is approximately 14 mm {0.55 in} to prevent the scissors gear from rotating under the spring force.