SUPPLY PUMP CONSTRUCTION/OPERATION [WL-C, WE-C]

id0114b6102700

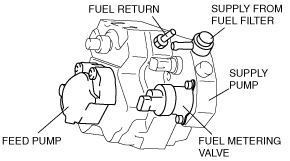

• The supply pump is driven by the gear. The feed pump is driven by the supply pump drive shaft.

• The supply pump has three pumping elements with 120° offset (displacement pumps).

• The fuel metering valve is located in the supply duct between the feed pump and the supply pump, and meters the quantity of fuel which is to be delivered into the high-pressure chamber in accordance with the current operating status of the engine.

• Any surplus fuel is returned to the fuel tank via the fuel return.

Flow of fuel through fuel pump

Feed Pump Operation

• The feed pump is designed as a gear pump and delivers the required fuel to the supply pump.

Essential components are two counter‐rotating, meshed gear wheels that transport the fuel in the tooth gaps from the intake side to the pressure side.

The contact line of the gears forms a seal between the intake side and the pressure side and prevents the fuel from flowing back.

The delivery quantity is approximately proportional to engine speed. For this reason, fuel‐quantity control is required.

For fuel‐quantity control purposes, there is an overflow valve incorporated in the supply pump.

Overflow Valve Operation

• High‐pressure generation (up to 160 MPa {1,632 kgf/cm

2, 23,206 psi}) means high thermal load on the individual components of the supply pump. The mechanical components of the supply pump must also be lubricated sufficiently to ensure durability.

The overflow valve is designed to ensure optimum lubrication or cooling for all operating conditions.

At lower engine speeds (low feed pump pressure) the control plunger is moved only slightly out of its seat. The lubrication/cooling requirement is correspondingly low.

A small amount of fuel is released to lubricate/cool the pump via the restriction at the end of the control plunger

The supply pump features automatic venting. Any air in the supply pump is vented through the restriction.

With increasing engine speed (increasing feed pump pressure), the control plunger is moved further against the compression spring.

Increasing engine speeds require increased cooling of the supply pump. Above a certain pressure, the supply pump cooling bypass is opened and the flow rate through the supply pump is increased.

At high engine speeds (high feed pump pressure), the control plunger is moved further against the compression spring. The supply pump cooling bypass is now fully open (maximum cooling).

Excess fuel is transferred via the return bypass to the intake side of the feed pump.

In this way, the internal pump pressure is limited to a maximum of 600 kPa {6.12 kgf/cm2, 87.0 psi}.

High Pressure Generation

• The supply pump is driven via the drive shaft.

An eccentric element is fixed to the drive shaft and moves the three plungers up and down according to the cam lobes of the eccentric element.

Fuel pressure from the feed pump is applied to the inlet valve. If the feed pump pressure exceeds the internal pressure of the high-pressure chamber (pump plunger in TDC position), the inlet valve opens.

Fuel is now pressed into the high‐pressure chamber, which moves the pump plunger downwards (intake stroke).

If BDC of the pump plunger is exceeded, the inlet valve closes due to the increasing pressure in the high‐pressure chamber. The fuel in the high‐pressure chamber can no longer escape.

As soon as the pressure in the high‐pressure chamber exceeds the pressure in the common rail, the outlet valve opens and the fuel is pressed into the common rail via the high‐pressure connection (delivery stroke).

The pump plunger delivers fuel until TDC is reached. After this, the pressure drops so that the outlet valve closes.

As the pressure on the remaining fuel is reduced, the pump plunger moves downward.

If the pressure in the high‐pressure chamber falls below the transfer pressure, the inlet valve reopens and the process starts again.

Zero Delivery Restriction Operation

• The zero-delivery throttle is installed to the supply pump. The fuel metering unit sends a quantity of fuel to the plunger even during zero-delivery. To prevent this, the fuel is returned to the feed pump inlet via the orifice of the zero-delivery throttle, ensuring zero fuel delivery to the plunger. Except during zero-delivery, essentially no fuel is sent to the orifice due to the throttle effect, instead it is sent to the plunger.