FUEL INJECTION CONTROL OPERATION [F2]

id014094101900

Fuel Injection Time

Control outline

• The PCM controls the fuel injection time to obtain the optimum air/fuel stoichiometric mixture ratio at all engine operation ranges according to engine operating condition.

Fuel Injection Timing

Control outline

-

• There are two types of injection timing, “synchronized timing” and “non-synchronized timing”. With synchronized timing, fuel is injected at the preset crankshaft position. With non-synchronized timing, fuel is injected when certain conditions are satisfied regardless of the crankshaft position.

• When both synchronized and non-synchronized injections are required, both injections will be carried out on each specified timing. If the timing overlaps, injection will be carried out for their total time.

Synchronized injection

• There are the following types of synchronized control.

1 injection/1 ignition pulse:

Fuel is supplied by simultaneously providing one injection per SGT signal (four injection per cycle) to all cylinders. One injection period supplies a quarter of the fuel necessary for ideal combustion.

1 injection/1 crankshaft rotation (two-group injection)

Fuel is supplied to all cylinders simultaneously by giving one injection per crankshaft rotation (one injection per cycle). The determination for two-group injection is made by the SGT signal of the No.2 cylinder created in the distributor.

Non-synchronized injection

• There are the following types of non- synchronized control.

Idle non-synchronized control

• When the CTP switch is turned off, all cylinders are simultaneously injected for a certain period of time according to the engine coolant temperature.

Throttle non-synchronized

• When the throttle opening angle variation rate exceeded a specified value, fuel is simultaneously injected to all cylinders for a certain period of time according to the engine coolant temperature.

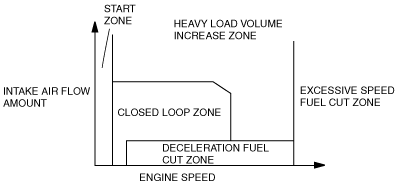

Control Zones

Operation outline

-

• The PCM controls effective injection time by dividing engine operating condition into five zones to control balanced air/fuel stoichiometric mixture ratio according to the engine and load conditions.

Start zone

• The purpose of this zone is to improve startability

• The start zone corresponds to an engine speed of less than 500 rpm.

• The final fuel injection amount in start zone is determined according to the engine coolant temperature and engine speed.

Excessive speed fuel cut zone

• The purpose of this zone is to protect the engine.

• Excessive speed fuel cut zone is when the engine speed is above 5,800 rpm for over 5 s or above 6,100 rpm.

• Fuel injection resumes when the engine speed has dropped below 5,700 rpm.

Deceleration fuel cut

• The purpose of this zone is to improve fuel economy and to prevent overheating of the TWC.

• In deceleration fuel cut zone, fuel injection is stopped when braking with loaded idling, engine speed above 1,300 rpm, and engine coolant temperature above 80 °C {176 °F}.

Heavy load volume increase zone

• The purpose of this zone is to improve drivability under heavy load condition.

• The heavy load volume increase zone is when charging efficiency is high with throttle opening angle more than preset value or engine speed is above 4,000 rpm.

• The fuel injection time for the heavy load volume increase zone is calculated using the following formula:

Fuel injection time = High altitude volume increase correction × Warm-up volume increase correction ×

Acceleration increase correction × Heavy load volume increase correction ×

Learning correction

• The heavy load volume increase correction is operated only in the heavy load volume increase zone.

Closed loop zone

• The purpose of this zone is to improve fuel economy and to reduce exhaust emission level.

• The control system is in the closed loop zone when it is in other than the above zones.

• The fuel injection time for the closed loop zone is calculated the following formula:

Fuel injection time = High altitude volume increase correction × (Warm-up volume increase correction +

Idle (load) volume increase correction + Idle (no load) volume increase correction) ×

Acceleration increase correction × Deceleration volume decrease correction ×

(Closed loop correction × Learning correction)

• The closed loop correction is operated only in the closed loop zone.

Corrections

|

Correction

|

Purpose

|

Condition

|

Action

|

|

Volume increase correction after start

|

To maintain engine speed stability after start

|

Certain period after start determined by ECT

|

Lower ECT → Larger correction

|

|

Warm-up volume increase correction

|

To maintain drivability during warm-up

|

According to ECT

|

Lower ECT → Larger correction

|

|

Acceleration volume increase/deceleration volume decrease correction

|

To maintain engine response during acceleration and drivability during deceleration

|

According to ECT

|

Lower ECT → Larger correction

|

|

Closed loop correction

|

To control air/fuel stoichiometric mixture ratio close to stoichiometric

|

When control is in closed loop zone

|

—

|

|

Learning correction

|

To deal with change in air/fuel stoichiometric mixture ratio caused by aging

|

At all times

|

—

|

|

Heavy load volume increase correction

|

To maintain drivability under heavy load

|

According to engine speed and charging efficiency when throttle opening angle more than preset value

|

High engine speed → Larger correction

Larger charging efficiency → Larger correction

|

|

Idle (load) volume increase correction

|

To maintain engine speed stability with load at idle

|

According to engine speed when idling under loaded condition with ECT more than 20 °C {68 °F} (in closed loop zone)

|

High engine speed → Larger correction

|

|

Idle (no load) volume increase correction

|

To maintain engine speed stability with no load at idle

|

When idling with engine speed below 1,000 rpm

|

When idling with engine speed below 1,000 rpm → Set amount of correction

|

|

High altitude volume increase correction

|

To adjust air/fuel ratio according to air density change at high altitude

|

When air pressure below 93 kPa {694 mmHg, 27 inHg}

|

High engine speed → Larger correction (Decreases when engine speed exceeds 3,000 rpm)

|

Fuel Cut Control

Dechoke control

-

Outline

-

• Dechoke control executes fuel cut to improve startability when the spark plug becomes fouled because of flooded engine.

-

Operation

-

• Fuel injection is cut if the throttle valve is held at wide open throttle during cranking (engine speed below 500 rpm).