FRONT BRAKE (DISC) INSPECTION

id041100800800

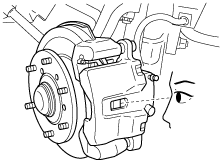

Disc Pad Thickness Inspection

1. Jack up the front of the vehicle on level ground and support it with safety stands.

2. Remove the wheels.

3. Look through the caliper inspection hole and verify the remaining thickness of the pad.

-

Minimum front disc pad thickness

-

2.0 mm {0.079 in} min.

Disc Plate Thickness Inspection

1. Measure the thickness of the disc plate.

-

• If the thickness is not within the specification, replace the disc plate.

-

Caution

-

• When it is necessary to machine the disc plate, make sure the disc plate is not removed from the vehicle when machined, excessive runout may result. Machine the disc plate with it installed on the vehicle.

-

Standard front disc plate thickness

-

4x2 (except high clearance model): 24.0 mm {0.945 in}

4x2 (high clearance model), 4x4: 28.0 mm {1.11 in}

-

Minimum front disc plate thickness

-

4x2 (except high clearance model): 22.0 mm {0.867 in}

4x2 (high clearance model), 4x4: 26.0 mm {1.03 in}

-

Minimum front disc plate thickness after machining using a brake lathe on-vehicle

-

4x2 (except high clearance model): 22.8 mm {0.898 in}

4x2 (high clearance model), 4x4: 26.8 mm {1.06 in}

Disc Plate Runout Inspection

1. Tighten the disc plate to the wheel hub using two wheel nuts. When measuring runout, measure at the outer edge of the disc plate surface.

-

Front disc plate runout limit

-

0.05 mm {0.002 in} max.