1. Engine harness inspection

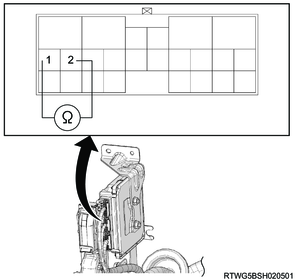

1) Disconnect the engine harness from the TCM.

2) Check for continuity between each connector terminal combinations listed in the table using a DMM.

Note

- Check that continuity is as specified in the table.

- A resistance value of 100 kΩ or more may be detected when resistance is measured between the terminals, but this is not a malfunction.

Caution

- Do not damage the terminals.

| Terminal name |

Continuity |

| NT+ - NT- |

Yes |

Legend

- NT+

- NT-

2. Turbine speed sensor inspection

1) Remove the turbine speed sensor from the transmission.

2) Check for continuity between each connector terminal combinations listed in the table using a DMM.

Note

- Check that continuity is as specified in the table.

- A resistance value of 100 kΩ or more may be detected when resistance is measured between the terminals, but this is not a malfunction.

Caution

- Do not apply impact to the turbine speed sensor.

- Do not damage the terminals.

| Terminal name |

Continuity |

| NT+ - NT- |

Yes |

Legend

- NT+

- NT-

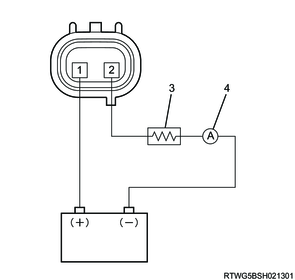

3) Connect the battery positive terminal to the NT+ terminal and the battery negative terminal to the NT- terminal via a 100 Ω resistor and ammeter.

Caution

- Do not apply impact to the turbine speed sensor.

- Do not damage the terminals.

Legend

- NT+

- NT-

- 100 Ω resistor

- Ammeter

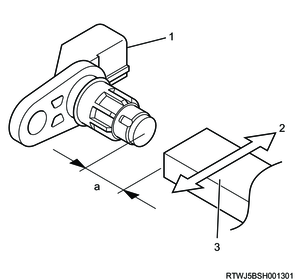

4) Inspect the current of the steel material (non-magnetic) while brushing to the left and right with the tip of the turbine speed sensor (within 5 mm {0.197 in}).

Caution

- Do not hit or damage the steel material with the turbine speed sensor when inspecting the current.

- Do not damage the terminals.

| Signal |

Current |

| High |

12.0 to 16.0 mA |

| Low |

4.0 to 8.0 mA |

Legend

- Turbine speed sensor

- Shaking direction

- Steel material

Measurement position

a. 5 mm {0.197 in} or less