1. Repair work

Warning

- Workshop manuals are created for qualified service technicians that have specialized training. If vehicle maintenance is performed by a person without the necessary qualifications or that has not received the appropriate training, damage may be caused to the vehicle, or harm may come to the service technician and people in the vicinity.

- If vehicle maintenance is performed without using the appropriate tools and devices, damage may be caused to the vehicle, or harm may come to the service technician and people in the vicinity.

- If vehicle maintenance is performed using a procedure other than indicated in the workshop manual, damage may be caused to the vehicle, or harm may come to the service technician and people in the vicinity.

Caution

- When replacing parts, make sure to use only genuine parts because the appropriate maintenance and repair procedures are essential to maintaining the safety of the service technician and the safety and reliability of the vehicle.

- Make sure to read the workshop manual thoroughly before performing any work because it contains procedures and information that must be followed when performing vehicle maintenance and repairs.

- When performing maintenance and repairs, be sure to correctly use the special tools specially designed for each purpose.

- To ensure the safety of the service technician and the safety and reliability of the vehicle, do not perform procedures or use tools other than those recommended in the workshop manual.

- To ensure accidents do not occur during maintenance and repair procedures, to prevent damage to the vehicle due to inappropriate procedures, and to ensure the safety and reliability of the vehicle, the workshop manuals indicate information that must be followed particularly closely, using the terms "Warning", "Caution", and "Supplement".

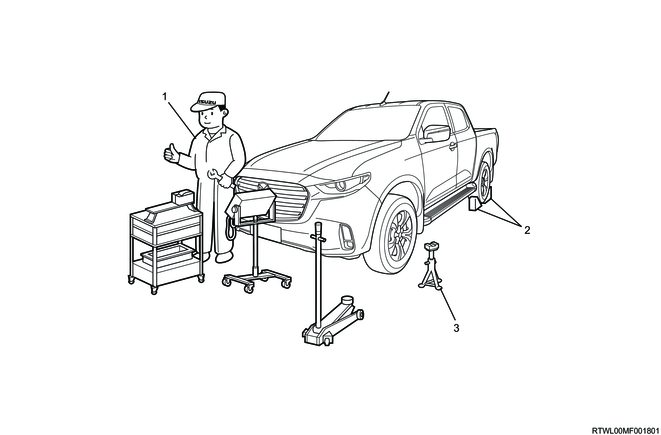

Jacking up

Legend

- Clean and safe work clothes

- Installation of chock blocks

- Support using a rigid rack after jacking up vehicle

Caution

- Prepare tools, instruments, and special tools in advance.

- Prepare the parts that require replacements and parts that cannot be re-used in advance.

- The service technician must wear a clean service technician uniform, hat, and safety footwear.

- Make sure to use a seat cover, etc.

- Disconnect the negative terminal of the battery cable in advance.

- Always remember to perform operations in a safe manner.

- Make sure to use chock blocks when the vehicle is jacked up.

- After jacking up, make sure to support the specified position using a rigid rack.

- When lifting up the vehicle using a lift, make sure to set the safety device.

- When performing a procedure with two or more people, make sure to ensure each other's safety before performing an action.

- Do not leave the engine running for an extended period of time or perform painting in a poorly ventilated working environment.

- Make sure to use the special tools if the procedure requires them for the work.

- Do not use tools such as a wrench that has lost its edges, a hammer with frayed edges, or a chipped chisel.

- When performing work using a device such as a grinder, crane, or welder, make sure that a qualified technician performs the procedure while paying sufficient attention to the handling precautions.

- When performing maintenance on the fuel system, make sure to check that there is no fuel leakage.

- When handling volatile materials, take care that they do not catch fire.

- Make sure to wipe away any oil that sticks to rubber parts, as it can cause deterioration.

- Arrange removed parts in the correct order and ensure they do not get mixed up with parts that cannot be re-used.

- Perform sufficient cleaning and washing when performing assembly/installation.

- Perform sufficient grease removal on areas where applying liquid gasket, etc.

- After completing the procedure, perform a final check to confirm that the problem has been solved.

- Check that there is no fuel, oil, or engine coolant leakage.

- Disconnect battery cables before conducting welding.

- Disconnect all control cables before conducting welding.

- Turn all switches OFF before conducting welding work.

- Make sure the ground connection for the welder is as close to the welding area as possible.

2. Vehicles with supplemental restraint system

Warning

- Do not use the SRS components designed for other vehicles or models.

- Make sure to check the part numbers and use the SRS components intended for the target vehicle.

Caution

- When performing inspection work, make sure to turn the ignition switch to the "LOCK" position.

- Be careful to avoid applying strong impacts to the SRS airbag, satellite sensor, and surrounding areas.

- When conducting maintenance of SRS components and SRS harnesses or performing the following work, make sure to follow the workshop manual procedures as temporary deactivation of the SRS is necessary.

| Work in which SRS airbag deactivation is necessary |

| Repairs around the steering wheel |

| Repairs around the instrument panel |

| Repairs around the glove box |

| Repairs around the fuse box |

| Repairs around the knee bolster panel (passenger side). |

| Repairs around the dash board |

| Repairs around the center console |

| Repairs around the seat belts |

| Installing products such as car stereos |

| Cab bodywork and painting |

3. Replacement parts and parts number

Caution

- Whenever disassembly is performed, make sure to replace the packing, oil seals, O-rings, crimping lock nuts, bending lock plates, cotter pins, etc., with new ones.

- Make sure to check the supply system and part numbers in the parts catalog as part numbers indicated in this manual may differ from the supply system and are subject to change.

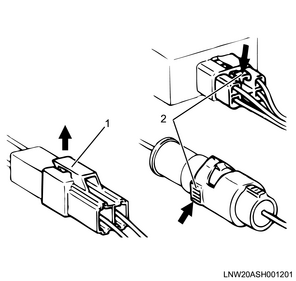

4. Connector handling

Note

- Disconnection of the connectors

Caution

- Many connectors have a lock to ensure secure connections.

- The two types of locks generally used are those that open by lifting the release area of the lock, and those that open by pressing the release area.

- Before disconnecting the connector, determine in advance the connector lock type.

Lock connector

Legend

- Lock

- Release area

Caution

- To remove the connector, firmly hold the male and female sections of the connector and pull them apart carefully after releasing the lock.

- When removing the waterproof connector, remove dust or moisture adhering to the connector by blowing air across it, etc.

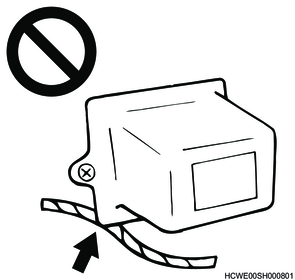

If dust or moisture enters the connector, remove it before connecting the connector. As for moisture, dry well to prevent rust. - Do not pull the harness when disconnecting the connector, as this may cause the wiring to come out or disconnect.

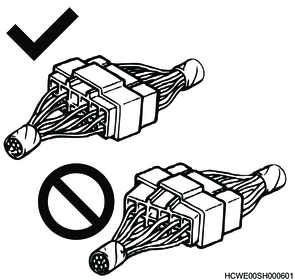

Handling the connectors

Note

- Connecting connectors

Caution

- Securely hold the female side and male side of the connector, and align the female side and male side of the connector correctly.

- Firmly push them together until both sides click into place.

Connecting connectors

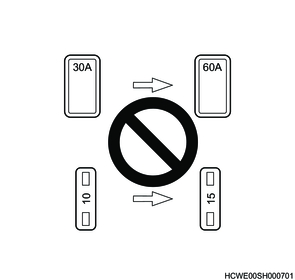

5. Electrical parts handling

Warning

- If the fuse blows out, make sure to replace it with a non-defective fuse of the same capacity after identifying the cause of the blowout.

- If you use a fuse with high capacity, the fuse will not perform its function when excess current flows through it.

- This may cause parts, wiring, etc. to burn, and can result in a vehicle fire.

Handling the fuse

Caution

- Even for electric parts that are installed outside the cab and are waterproofed, try as much as possible to avoid exposing them directly to high pressure water when washing the vehicle (cover them with plastic sheets, etc.).

- Handle electronic parts with sufficient care, and do not damage the parts by dropping or throwing them.

Handling electronic components

Caution

- When installing electronic parts, take care to ensure the harness does not get stuck and do not forcibly push the harness in.

Pinching the harness

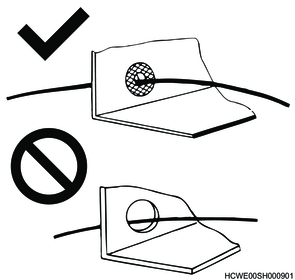

Caution

- Make sure that all connections are clean and secure.

- Use grommets or tubes to prevent damage to harnesses that may come in contact with the sharp edges or surfaces of other parts.

Protecting the harness

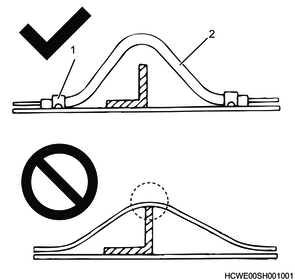

Caution

- When wiring a harness by diverting it around other parts, give the harness a sufficient amount of slack, and use a protection tube and clip to ensure it does not contact surrounding parts.

Harness routing

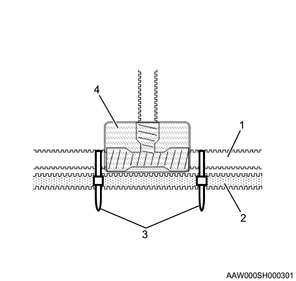

Legend

- Clip

- Protection tube

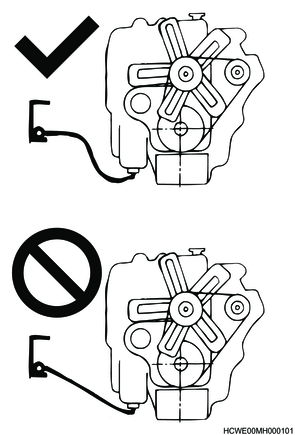

Caution

- For wiring between the engine and chassis, give the wiring sufficient slack to prevent wear and damage caused by vibration.

Engine and transmission wiring

Caution

- When securing additional wires along existing harnesses, install band clips on the protective materials (corrugated tubes, vinyl chloride tubes, rigid tubes, protectors, etc.) installed on the existing harnesses.

Repairing the harness

Legend

- Existing harness (With protective material)

- Additional harness

- Band clip for securing harnesses

- Area where securing with band clips is prohibited

6. Commercial electronic products

Caution

- If commercial electronic products such as lights, audio systems, or wireless devices are installed to the vehicle, turn the power of the devices OFF in advance.

- Otherwise, remove the commercial electronic products before inspection or maintenance.

7. Failure by electrostatic discharge

Caution

- Because a high voltage applied to electronic components due to electrostatic discharge may result in malfunctions, touch a known good ground before inspecting or replacing related parts.

- Do not directly touch the connector pins of related components or rub them with other parts or covers, etc.

- If replacing electronic components, connect the parts to a known good ground while still in their packaged state and then remove them while taking care to prevent the connector pins from coming in contact with the packaging.