1. Fuel supply pump functional inspection description of function

The supply pump functional inspection is a systematic method for checking problems caused by malfunctions in the fuel supply system.

The supply pump functional inspection is a starting point for trouble diagnosis caused by a fuel system failure.

Understanding and correctly using this diagnostic chart reduces diagnostic time and prevents the replacement of good parts.

2. Fuel supply pump functional inspection

1. Fuel inspection

1) Inspect the fuel amount.

If there is no fuel, add fuel and go to Fuel piping inspection.

2. Fuel piping inspection

1) Inspect the fuel piping for fuel leakage as well as collapsing, bending, cracking, or looseness of the piping.

If an abnormal condition is found, repair the fuel piping and go to Fuel rail pressure inspection.

3. Fuel rail pressure inspection

1) While cranking the engine for 5 seconds, observe the Fuel Rail Pressure display on the scan tool.

Standard: 30 MPa { 4,350 psi }

If the reading is more than or equal to the standard value, go to Engine startup inspection.

If the reading is less than the standard value, go to Bleeding air from fuel piping.

4. Bleeding air from the fuel piping

1) Bleed air from the fuel piping.

2) While cranking the engine for 5 seconds, observe the Fuel Rail Pressure display on the scan tool.

Standard: 30 MPa { 4,350 psi }

If the reading is more than or equal to the standard value, go to Engine startup inspection.

If the reading is less than the specified value, go to Inspection for fuel leakage.

5. Inspection for fuel leakage from injector

1) Remove the glow plug from the cylinder head.

2) Crank the engine for 10 seconds.

3) Inspect for fuel leakage into the combustion chamber.

If there is fuel leakage, go to the applicable cylinder injector replacement.

If there is no fuel leakage, go to Fuel filter element replacement.

6. Injector replacement

1) Replace the injector.

2) Set the Injector ID Code on the ECM.

3) While cranking the engine for 5 seconds, observe the Fuel Rail Pressure display on the scan tool.

Standard: 30 MPa { 4,350 psi }

If the reading is more than or equal to the standard value, go to Engine startup inspection.

If the reading is less than the standard value, go to Fuel filter element replacement.

7. Fuel filter element replacement

1) Replace the fuel filter element and the pre-fuel filter element.

2) While cranking the engine for 5 seconds, observe the Fuel Rail Pressure display on the scan tool.

Standard: 30 MPa { 4,350 psi }

If the reading is more than or equal to the standard value, go to Engine startup inspection.

If the reading is less than the standard value, go to Fuel supply pump replacement.

8. Fuel supply pump replacement

1) Replace the fuel supply pump.

2) Perform the learning of the fuel supply pump on the ECM.

While cranking the engine for 5 seconds, observe the Fuel Rail Pressure display on the scan tool.

Standard: 30 MPa { 4,350 psi }

If the reading is more than or equal to the standard value, go to Engine startup inspection.

If the reading is less than the standard value, go to 15D. Symptom "rough, unstable" or "cuts out".

Refer to "202.Engine 15D.Symptom(4JJ3 without DPD) rough, unstable".

Refer to "202.Engine 15D.Symptom(4JJ3 without DPD) cuts out".

9. Engine startup inspection

1) Reconnect all of the disconnected harness connectors and components.

2) Clear the DTC with a scan tool.

3) Turn OFF the ignition switch and wait for 30 seconds.

4) Start the engine.

If the engine started, go to Fuel rail pressure response check.

If the engine does not start, go to 15D. Symptom "rough, unstable" or "cuts out".

Refer to "202.Engine 15D.Symptom(4JJ3 without DPD) rough, unstable".

Refer to "202.Engine 15D.Symptom(4JJ3 without DPD) cuts out".

10. Fuel rail pressure response check

1) Operate the accelerator pedal and check whether the fuel rail pressure and engine speed respond appropriately.

If the fuel rail pressure and engine speed respond appropriately, the system is normal.

If the fuel rail pressure and engine speed do not respond appropriately, go to 15D. Symptom "Lack of power, sluggishness or sponginess" or "Hesitation, sag or stumble".

Refer to "202.Engine 15D.Symptom(4JJ3 without DPD) lack of power, sluggishness or sponginess".

Refer to "202.Engine 15D.Symptom(4JJ3 without DPD) hesitation, sag or stumble".

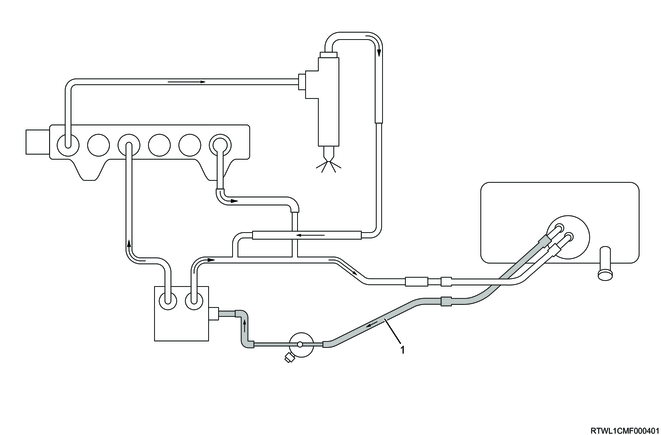

Fuel piping inspection locations

Legend

- Area of inspection

Engine speed (Fuel rail pressure) response check method