1. Preliminary and post procedures

1. Preliminary procedures

1) Open the engine hood.

2) Disconnect the battery cable from the battery negative terminal.

Caution

- After turning OFF the ignition switch (power mode for models with passive entry and start system), do not disconnect the battery cable within 3 minutes.

- If the battery cable is disconnected within 3 minutes, the vehicle electronic control system may malfunction.

- If the battery cable is disconnected, perform the setting of the front door power window switch with AUTO UP/AUTO DOWN function after connecting the battery negative terminal.

2. Differential oil drain

1) Remove the filler plug and gasket from the rear axle.

2) Remove the drain plug and gasket from the rear axle, and drain the differential oil from the rear axle.

3. Disc wheel removal

1. Models with aluminum wheels

1) Move the vehicle to a flat surface.

2) Pull the parking brake lever.

3) Secure the vehicle using chock blocks.

4) Raise the vehicle.

Note

- Jack up the vehicle but not to an extent that the tire leaves the ground.

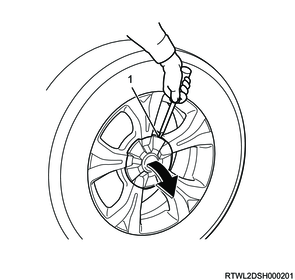

5) Remove the wheel cap from the disc wheel.

Note

- Insert a tool with flat tip such as a flathead screwdriver into the wheel cap groove to remove.

Legend

- Wheel cap groove

6) Loosen the wheel nuts.

Note

- Loosen without allowing the disc wheel to rattle.

Caution

- At this time, do not remove the wheel nuts.

7) Raise the vehicle.

Note

- Jack up the vehicle until the tire is completely off the ground.

- Support the frame using a chassis stand as necessary.

8) Remove the disc wheel from the vehicle.

2. Models with steel wheels

1) Move the vehicle to a flat surface.

2) Pull the parking brake lever.

3) Secure the vehicle using chock blocks.

4) Raise the vehicle.

Note

- Jack up the vehicle but not to an extent that the tire leaves the ground.

5) Remove the wheel cap from the disc wheel.

6) Loosen the wheel nuts.

Note

- Loosen without allowing the disc wheel to rattle.

Caution

- At this time, do not remove the wheel nuts.

7) Raise the vehicle.

Note

- Jack up the vehicle until the tire is completely off the ground.

- Support the frame using a chassis stand as necessary.

8) Remove the disc wheel and wheel cap from the vehicle.

4. Rear propeller shaft removal

Caution

- When removing the propeller shaft from the transmission, cover the slip yoke with a cloth to prevent the oil seal contact surface from damage.

1. Two-piece type

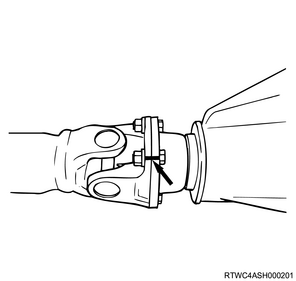

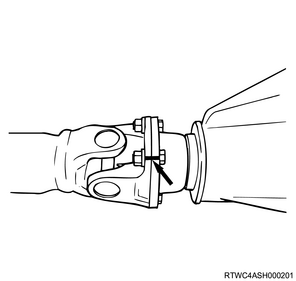

1) Draw alignment marks on the flange yoke, flange, and parking brake drum.

Caution

- Because the propeller shaft is adjusted to have a precise balance, always place alignment marks on each of the joints before removing or disassembling.

2) Remove the center bearing from the vehicle.

3) Remove the propeller shaft from vehicle.

Note

- Remove in order starting from the rear of the vehicle and moving forward.

4) Install the plug to the transmission rear end hole.

To prevent oil leakage

2. One-piece type

1) Draw alignment marks on the flange yoke, flange, and parking brake drum.

Caution

- Because the propeller shaft is adjusted to have a precise balance, always place alignment marks on each of the joints before removing or disassembling.

2) Remove the propeller shaft from vehicle.

Note

- Remove in order starting from the rear of the vehicle and moving forward.

3) Install the plug to the transmission rear end hole.

To prevent oil leakage

5. Brake drum removal

1) Release the parking brake lever.

2) Remove the brake drum from the rear axle shaft.

6. Wheel speed sensor removal

1. Precautions for wheel speed sensor removal (ABS specifications)

Caution

- Be careful not to damage the wheel speed sensor during service works, since it may cause ABS failure.

- Because ABS abnormalities or malfunctions may occur if the wheel speed sensor is improperly installed, follow the precautions detailed in the outlined procedure when installing, removing, or replacing the wheel speed sensor.

- When it is difficult to remove the wheel speed sensor body due to rust, use rust penetrant etc., and then carefully remove the sensor body by shifting it little by little until it comes free.

- Do not bump or step on the removed sensor.

- Do not remove the sensor unit by hammering.

- Do not insert a flat-head screwdriver or the like into the gap to remove it forcibly.

- Do not pull the sensor harness.

2. Removal (ABS specifications)

1) Disconnect the harness clip from the harness.

2) Remove the wheel speed sensor from the rear axle case.

7. Brake shoe removal

1) Remove the adjust lever spring from the adjust lever and brake shoe.

2) Remove the following parts from the brake shoe.

- Adjust lever ring

- Adjust lever

Caution

- Do not reuse the adjust lever ring.

Note

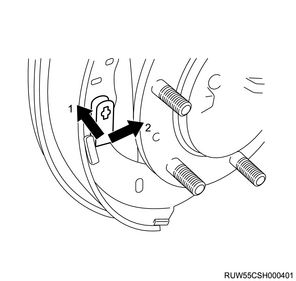

- Remove the shoe holding spring from the shoe holder pin.

- While holding the shoe holding spring by pushing it toward the brake shoe, remove it from the shoe holder pin by turning it.

Caution

- Do not reuse the shoe holding spring.

Legend

- Hold by pushing toward the brake shoe.

- Turn.

3) Remove the shoe holder pin from the brake shoe.

Caution

- Do not reuse the shoe holder pin.

4) Remove the lower spring from the brake shoe.

Note

- Remove the brake shoe and lower spring by sliding them toward the ground.

Legend

- Lower spring

5) Remove the adjuster and upper spring from the brake shoe.

6) Remove the upper spring from the adjuster.

7) Remove the brake shoe from the back plate.

8. Parking brake cable disconnect

1. Parking brake cable disconnection precautions

Caution

- Do not twist or bend the cable.

Operation will be insufficient if the cable is damaged.

2. Disconnection from brake

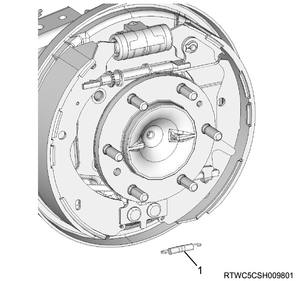

1) Disconnect the parking brake cable from the parking lever.

2) Disconnect the parking brake cable from the back plate.

Note

- Press the lock protrusion of the cable using a 12 mm hexagonal offset box wrench and disconnect the parking brake cable.

Legend

- 12 mm hexagonal offset box wrench

9. Rear wheel cylinder removal

1) Disconnect the brake pipe from the wheel cylinder.

2) Remove the wheel cylinder from the back plate.

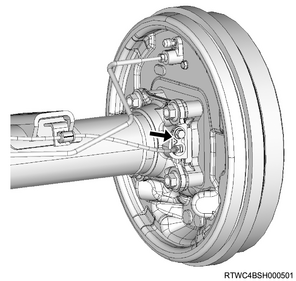

10. Rear axle shaft removal

1) Remove the rear axle shaft from the rear axle.

Note

- Remove together with the following parts.

- Bearing holder

- Back plate

- Oil catcher

2) Remove the axle case oil seal from the rear axle case.

Caution

- Do not reuse the axle case oil seal.

- Because the axle case oil seal is damaged when the rear axle shaft is removed, replace the axle case oil seal.

11. Final drive removal

1) Remove the final drive from the rear axle.