1. Piston installation

1) Install the connecting rod bearing to the connecting rod.

2) Apply engine oil to the sliding surface of the connecting rod bearing.

Caution

- Do not apply engine oil to the connecting rod bearing installation surface and the back surface of the bearing.

3) Sufficiently apply the engine oil to the following locations.

- Piston ring

- Piston ring groove

- Piston side surface

- Cylinder bore surface

4) Turn the crankshaft in the forward direction and align to top dead center.

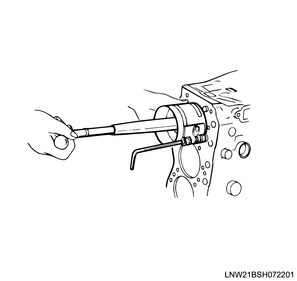

5) Install the piston to the cylinder block using the special tool.

Note

- Face the piston front mark towards the front.

- Use the piston ring compressor to insert the piston into the cylinder block.

SST: 5-8840-9018-0 - piston setting tool

Caution

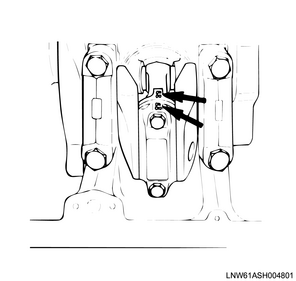

- When pushing the piston, do not allow the connecting rod to interfere with the oil jet.

- If the crank pin is at bottom dead center, the connecting rod may hit and damage the oil jet.

- Do not damage the cylinder block inner surface.

6) Install the connecting rod bearing to the bearing cap.

7) Apply engine oil to the sliding surface of the connecting rod bearing.

Caution

- Do not apply engine oil to the connecting rod bearing installation surface and the back surface of the bearing.

8) Apply engine oil to the threaded portions and seating surfaces of the bolts.

9) Temporarily tighten the bearing caps to the connecting rods after matching their cylinder numbers.

Caution

- Do not reuse the connecting rod bolts.

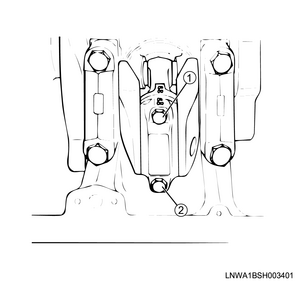

10) Final tighten the bearing cap bolts to the connecting rod in the order shown in the diagram, using a torque wrench and the special tool.

Tightening torque: 30 N・m { 3.1 kgf・m / 22 lb・ft } 1st time

Tightening Angle : 90 to 105 ° 2nd time

11) Turn the crankshaft and check that it turns smoothly without interference.

Caution

- Check that there is no oil jet deformation and that there is no interference with other parts.