1. Exhaust differential pressure sensor vehicle inspection

1. Sensitivity inspection

To determine whether the cause of DTC set is due to abnormal sensitivity of the exhaust differential pressure sensor, perform sensitivity inspection.

1) Disconnect the 2 differential pressure hoses from the exhaust differential pressure sensor.

Caution

- Do not remove the exhaust differential pressure sensor.

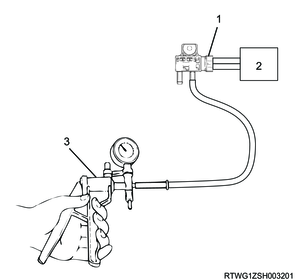

2) Referring to the diagram, connect the air pump to the exhaust differential pressure sensor.

Legend

- Exhaust differential pressure sensor connector

- ECM

- Air pump

3) Connect the scan tool to the DLC.

4) Turn ON the ignition switch.

5) Use the air pump to gradually increase pressure, and observe the Exhaust Differential Pressure Sensor parameter on the scan tool.

| Specified pressure |

Standard value |

| 0 kPa { 0.0 kgf/cm2 / 0 psi } |

0.750 V |

| 30 kPa { 0.3 kgf/cm2 / 4 psi } |

1.920 V |

| 75 kPa { 0.8 kgf/cm2 / 11 psi } |

3.675 V |

Note

- If the voltage shown on the scan tool is almost equal, the exhaust differential pressure sensor is normal.

- Replace the exhaust differential pressure sensor if the measured value is not the standard value.

6) Disconnect the air pump from the exhaust differential pressure sensor.

7) Align the markings, and then connect differential pressure hoses to the exhaust differential pressure sensor.

Caution

- Do not incorrectly assemble differential pressure hoses.

- Install the differential pressure hose clip securely so that there is no gas leakage.

- Do not use cracked hoses.

- If there is gas leakage from connections, the sensor may malfunction.

- After starting the engine, verify that there is no gas leakage.

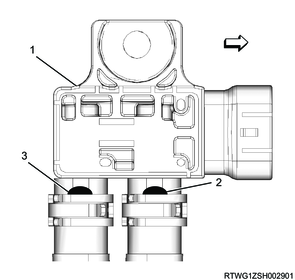

Legend

- Exhaust differential pressure sensor

- White paint section

- Green paint section

8) Connect the connector to the exhaust differential pressure sensor.

2. Exhaust differential pressure sensor inspection

1) Inspect the exhaust differential pressure sensor for the following.

- Inspect for dirt and other foreign material attached to the sensor section.

- Inspect for causes of poor connections such as collapsing or bending of the terminals.