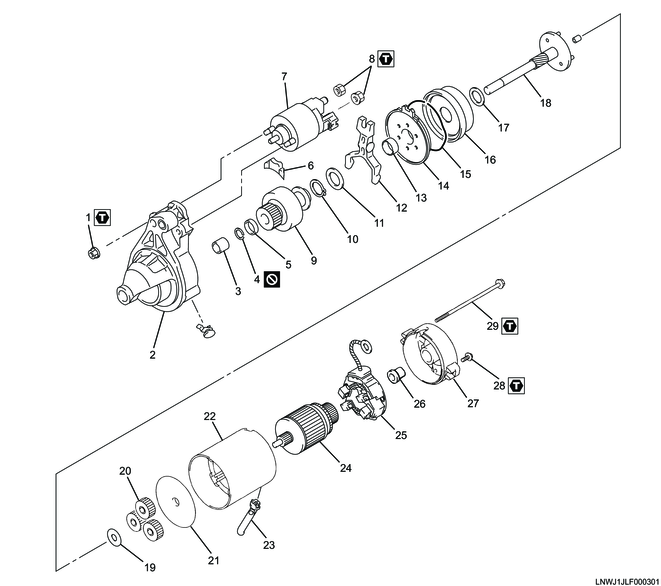

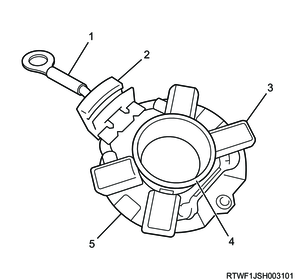

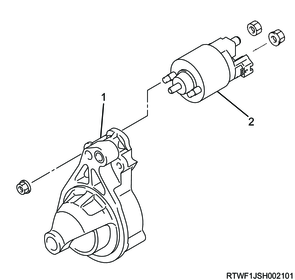

1. Component views

Starter motor

Part name

- Nut

- Housing

- Bearing

- Snap ring

- Pinion stopper

- Dust cover

- Magnetic switch

- Nut

- Pinion and overrunning clutch

- Snap ring

- Washer

- Shift lever

- Bearing

- Shock absorber

- Starter spring

- Internal gear

- Washer

- Clutch shaft

- Washer

- Planetary gear

- Plate

- Yoke

- M-terminal lead wire

- Armature

- Brush holder

- Bearing

- Rear cover

- Screw

- Through bolt

Tightening torque

1: 7.5 N・m { 0.76 kgf・m / 66.4 lb・in }

8: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

28: 1.5 N・m { 0.15 kgf・m / 13.3 lb・in }

29: 5.5 N・m { 0.56 kgf・m / 48.7 lb・in }

2. Starter motor reassembly

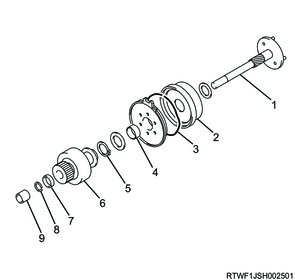

1) Install the following parts to the clutch shaft.

- Bearing

- Snap ring

- Pinion stopper

- Pinion and overrunning clutch

- Starter spring

- Internal gear

Legend

- Clutch shaft

- Internal gear

- Starter spring

- Bearing

- Snap ring

- Pinion and overrunning clutch

- Pinion stopper

- Snap ring

- Bearing

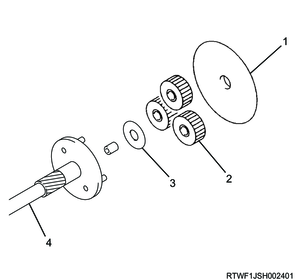

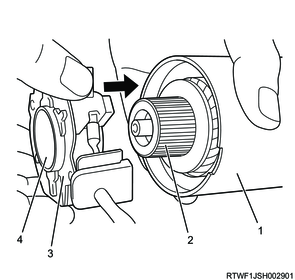

2) Install the planetary gear to the clutch shaft.

Legend

- Plate

- Planetary gear

- Washer

- Clutch shaft

3) Install the shift lever to the housing.

Legend

- Housing

- Shift lever

4) Install the pinion, overrunning clutch, and the clutch shaft as a set to the housing.

5) Install the yoke and plate to the housing.

6) Install the armature to the housing.

Legend

- Yoke

- Alignment mark

- Armature

7) Install the 4 brushes to the brush holder.

8) Prepare the brush holder.

Note

- If reusing a brush holder, insert the brush into the brush holder with a collar that is the same diameter as the commutator.

Caution

- Do not damage the brush.

Legend

- M-terminal lead wire

- Rubber seal

- Brush holder

- Collar

- Holder plate

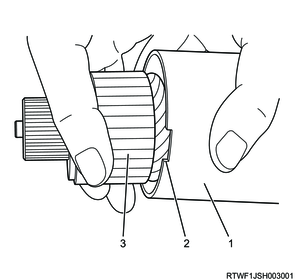

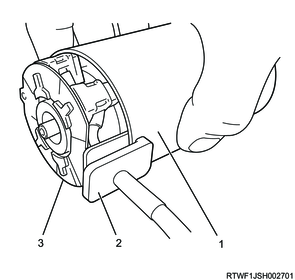

9) Referring to the diagram, install the brush holder to the commutator while gradually pulling out the collar.

Caution

- Do not damage the commutator surface.

- Insert it slowly until the collar comes out completely.

Legend

- Yoke

- Commutator

- Brush holder

- Collar

Legend

- Yoke

- Brush holder

- Collar

10) Align the rubber seal with the alignment mark.

Note

- Firmly push the rubber seal into the alignment mark.

Legend

- Yoke

- Rubber seal

- Brush holder

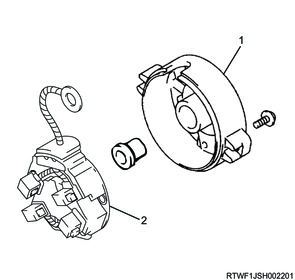

11) Install the rear cover to the yoke.

Tightening torque: 5.5 N・m { 0.56 kgf・m / 48.7 lb・in } Through bolt

Tightening torque: 1.5 N・m { 0.15 kgf・m / 13.3 lb・in } Screw

Legend

- Rear cover

- Brush holder

12) Install the dust cover to the housing.

13) Install the magnetic switch to the housing.

Note

- Align the marking to install.

Tightening torque: 7.5 N・m { 0.76 kgf・m / 66.4 lb・in }

Legend

- Housing

- Magnetic switch

14) Connect the lead wire of the magnetic switch to the magnetic switch M-terminal.

Tightening torque: 10 N・m { 1.0 kgf・m / 89 lb・in }

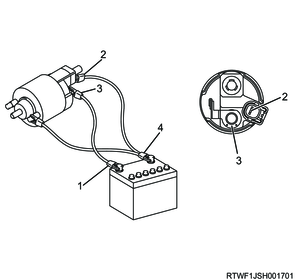

1. Pull-in test

Caution

- Be sure to perform the test with the starter motor fully assembled.

- The yoke lead wire must not be connected to the M-terminal.

- To prevent coil seizure, complete the test as quickly as possible.

- Complete the test within 3 to 5 seconds.

1) Connect the battery negative terminal to the starter motor and M-terminal.

2) Connect the battery positive terminal to the S-terminal.

Note

- If current is flowing from the battery positive terminal to the S-terminal, the pinion should pop out.

Legend

- Positive terminal

- S-terminal

- M-terminal

- Negative terminal

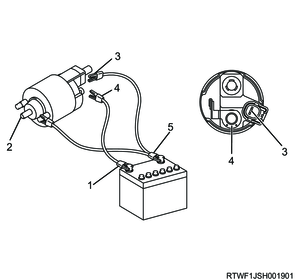

2. Hold-in test

1) Disconnect the M-terminal lead wire from the M-terminal.

Note

- The pinion should continue popping out.

Legend

- Positive terminal

- Plunger

- S-terminal

- M-terminal

- Negative terminal

3. Return test

1) Disconnect the battery positive lead of the S-terminal from the S-terminal.

Note

- The pinion should be returned to the specified position.

Legend

- Positive terminal

- Plunger

- S-terminal

- M-terminal

- Negative terminal

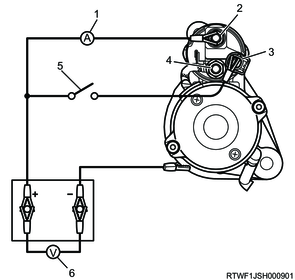

4. No-load test

1) Referring to the diagram, connect the starter to the battery.

Caution

- Use a sufficiently thick electric wire, and securely tighten the connection.

Legend

- Ammeter

- B-terminal

- S-terminal

- M-terminal

- Switch

- Voltmeter

2) Close the switch, and check the current and voltage.

Caution

- If the reading is outside the standard range, disassemble and inspect once again.

Standard: 11.5 V

Standard: 90 A or less

Standard: 2,600 rpm or more