1. List of standard bolt and nut tightening torques

1. Standard bolts and nuts for which no tightening torques are specified

| Strength category |

4.8 4T |

7T |

||

| Bolt head shape |

Hex bolt |

Flange bolt |

Hex bolt |

Flange bolt |

| M6 x 1 |

3.9 to 7.8 N・m { 0.4 to 0.8 kgf・m / 34.5 to 69.0 lb・in } |

4.6 to 8.5 N・m { 0.5 to 0.9 kgf・m / 40.7 to 75.2 lb・in } |

4.9 to 9.8 N・m { 0.5 to 1.0 kgf・m / 43.4 to 86.7 lb・in } |

5.7 to 10.6 N・m { 0.6 to 1.1 kgf・m / 50.4 to 93.8 lb・in } |

| M8 x 1.25 |

9.1 to 17.7 N・m { 0.9 to 1.8 kgf・m / 6.7 to 13.1 lb・ft } |

10.5 to 19.6 N・m { 1.1 to 2.0 kgf・m / 7.7 to 14.5 lb・ft } |

11.8 to 23.5 N・m { 1.2 to 2.4 kgf・m / 8.7 to 17.3 lb・ft } |

14.0 to 26.0 N・m { 1.4 to 2.7 kgf・m / 10.3 to 19.2 lb・ft } |

| M10 x 1.25 |

20.6 to 34.3 N・m { 2.1 to 3.5 kgf・m / 15.2 to 25.3 lb・ft } |

23.1 to 38.5 N・m { 2.4 to 3.9 kgf・m / 17.0 to 28.4 lb・ft } |

27.5 to 46.1 N・m { 2.8 to 4.7 kgf・m / 20.3 to 34.0 lb・ft } |

31.0 to 51.7 N・m { 3.2 to 5.3 kgf・m / 22.9 to 38.1 lb・ft } |

| *M10 x 1.5 |

19.6 to 33.3 N・m { 2.0 to 3.4 kgf・m / 14.5 to 24.6 lb・ft } |

22.3 to 37.2 N・m { 2.3 to 3.8 kgf・m / 16.4 to 27.4 lb・ft } |

27.5 to 45.1 N・m { 2.8 to 4.6 kgf・m / 20.3 to 33.3 lb・ft } |

30.3 to 50.4 N・m { 3.1 to 5.1 kgf・m / 22.3 to 37.2 lb・ft } |

| M12 x 1.25 |

49.0 to 73.5 N・m { 5.0 to 7.5 kgf・m / 36.1 to 54.2 lb・ft } |

54.9 to 82.3 N・m { 5.6 to 8.4 kgf・m / 40.5 to 60.7 lb・ft } |

60.8 to 91.2 N・m { 6.2 to 9.3 kgf・m / 44.8 to 67.3 lb・ft } |

68.1 to 102.0 N・m { 6.9 to 10.4 kgf・m / 50.2 to 75.2 lb・ft } |

| *M12 x 1.75 |

45.1 to 68.6 N・m { 4.6 to 7.0 kgf・m / 33.3 to 50.6 lb・ft } |

51.0 to 76.5 N・m { 5.2 to 7.8 kgf・m / 37.6 to 56.4 lb・ft } |

56.9 to 84.3 N・m { 5.8 to 8.6 kgf・m / 42.0 to 62.2 lb・ft } |

62.7 to 94.0 N・m { 6.4 to 9.6 kgf・m / 46.2 to 69.3 lb・ft } |

| M14 x 1.5 |

76.5 to 115.0 N・m { 7.8 to 11.7 kgf・m / 56.4 to 84.8 lb・ft } |

83.0 to 125.0 N・m { 8.5 to 12.7 kgf・m / 61.2 to 92.2 lb・ft } |

93.0 to 139.0 N・m { 9.5 to 14.2 kgf・m / 68.6 to 102.5 lb・ft } |

101.0 to 151.0 N・m { 10.3 to 15.4 kgf・m / 74.5 to 111.4 lb・ft } |

| *M14 x 2 |

71.6 to 107.0 N・m { 7.3 to 10.9 kgf・m / 52.8 to 78.9 lb・ft } |

77.2 to 116.0 N・m { 7.9 to 11.8 kgf・m / 56.9 to 85.6 lb・ft } |

88.3 to 131.0 N・m { 9.0 to 13.4 kgf・m / 65.1 to 96.6 lb・ft } |

94.9 to 142.0 N・m { 9.7 to 14.5 kgf・m / 70.0 to 104.7 lb・ft } |

| M16 x 1.5 |

104.0 to 157.0 N・m { 10.6 to 16.0 kgf・m / 76.7 to 115.8 lb・ft } |

116.0 to 173.0 N・m { 11.8 to 17.6 kgf・m / 85.6 to 127.6 lb・ft } |

135.0 to 204.0 N・m { 13.8 to 20.8 kgf・m / 99.6 to 150.5 lb・ft } |

150.0 to 225.0 N・m { 15.3 to 22.9 kgf・m / 110.6 to 166.0 lb・ft } |

| *M16 x 2 |

100.0 to 149.0 N・m { 10.2 to 15.2 kgf・m / 73.8 to 109.9 lb・ft } |

109.0 to 164.0 N・m { 11.1 to 16.7 kgf・m / 80.4 to 121.0 lb・ft } |

129.0 to 194.0 N・m { 13.2 to 19.8 kgf・m / 95.1 to 143.1 lb・ft } |

143.0 to 214.0 N・m { 14.6 to 21.8 kgf・m / 105.5 to 157.8 lb・ft } |

| M18 x 1.5 |

159.0 to 239.0 N・m { 16.2 to 24.4 kgf・m / 117.3 to 176.3 lb・ft } |

- |

216.0 to 324.0 N・m { 22.0 to 33.0 kgf・m / 159.3 to 239.0 lb・ft } |

- |

| *M18 x 2.5 |

151.0 to 226.0 N・m { 15.4 to 23.0 kgf・m / 111.4 to 166.7 lb・ft } |

- |

196.0 to 294.0 N・m { 20.0 to 30.0 kgf・m / 144.6 to 216.8 lb・ft } |

- |

| M20 x 1.5 |

206.0 to 310.0 N・m { 21.0 to 31.6 kgf・m / 151.9 to 228.6 lb・ft } |

- |

270.0 to 405.0 N・m { 27.5 to 41.3 kgf・m / 199.1 to 298.7 lb・ft } |

- |

| *M20 x 2.5 |

190.0 to 286.0 N・m { 19.4 to 29.2 kgf・m / 140.1 to 210.9 lb・ft } |

- |

249.0 to 375.0 N・m { 25.4 to 38.2 kgf・m / 183.7 to 276.6 lb・ft } |

- |

| M22 x 1.5 |

251.0 to 414.0 N・m { 25.6 to 42.2 kgf・m / 185.1 to 305.3 lb・ft } |

- |

363.0 to 544.0 N・m { 37.0 to 55.5 kgf・m / 267.7 to 401.2 lb・ft } |

- |

| *M22 x 2.5 |

218.0 to 328.0 N・m { 22.2 to 33.4 kgf・m / 160.8 to 241.9 lb・ft } |

- |

338.0 to 507.0 N・m { 34.5 to 51.7 kgf・m / 249.3 to 373.9 lb・ft } |

- |

| M24 x 2 |

359.0 to 539.0 N・m { 36.6 to 55.0 kgf・m / 264.8 to 397.5 lb・ft } |

- |

431.0 to 711.0 N・m { 43.9 to 72.5 kgf・m / 317.9 to 524.4 lb・ft } |

- |

| *M24 x 3 |

338.0 to 507.0 N・m { 34.5 to 51.7 kgf・m / 249.3 to 373.9 lb・ft } |

- |

406.0 to 608.0 N・m { 41.4 to 62.0 kgf・m / 299.4 to 448.4 lb・ft } |

- |

| Strength category |

8.8 |

9.8 9T |

||

| Bolt head shape |

Hex bolt |

Flange bolt |

Hex bolt |

Flange bolt |

| M6 x 1 |

5.6 to 11.2 N・m { 0.6 to 1.1 kgf・m / 49.6 to 99.1 lb・in } |

6.6 to 12.2 N・m { 0.7 to 1.2 kgf・m / 58.4 to 108.0 lb・in } |

- |

- |

| M8 x 1.25 |

13.4 to 26.8 N・m { 1.4 to 2.7 kgf・m / 9.9 to 19.8 lb・ft } |

15.9 to 29.6 N・m { 1.6 to 3.0 kgf・m / 11.7 to 21.8 lb・ft } |

16.7 to 30.4 N・m { 1.7 to 3.1 kgf・m / 12.3 to 22.4 lb・ft } |

18.1 to 33.6 N・m { 1.8 to 3.4 kgf・m / 13.3 to 24.8 lb・ft } |

| M10 x 1.25 |

31.3 to 52.5 N・m { 3.2 to 5.4 kgf・m / 23.1 to 38.7 lb・ft } |

35.4 to 58.9 N・m { 3.6 to 6.0 kgf・m / 26.1 to 43.4 lb・ft } |

37.3 to 62.8 N・m { 3.8 to 6.4 kgf・m / 27.5 to 46.3 lb・ft } |

42.3 to 70.5 N・m { 4.3 to 7.2 kgf・m / 31.2 to 52.0 lb・ft } |

| *M10 x 1.5 |

31.3 to 51.4 N・m { 3.2 to 5.2 kgf・m / 23.1 to 37.9 lb・ft } |

34.5 to 57.5 N・m { 3.5 to 5.9 kgf・m / 25.4 to 42.4 lb・ft } |

36.3 to 59.8 N・m { 3.7 to 6.1 kgf・m / 26.8 to 44.1 lb・ft } |

40.1 to 66.9 N・m { 4.1 to 6.8 kgf・m / 29.6 to 49.3 lb・ft } |

| M12 x 1.25 |

69.3 to 104.0 N・m { 7.1 to 10.6 kgf・m / 51.1 to 76.7 lb・ft } |

77.7 to 117.0 N・m { 7.9 to 11.9 kgf・m / 57.3 to 86.3 lb・ft } |

75.5 to 114.0 N・m { 7.7 to 11.6 kgf・m / 55.7 to 84.1 lb・ft } |

85.0 to 128.0 N・m { 8.7 to 13.1 kgf・m / 62.7 to 94.4 lb・ft } |

| *M12 x 1.75 |

64.8 to 96.1 N・m { 6.6 to 9.8 kgf・m / 47.8 to 70.9 lb・ft } |

71.4 to 107.0 N・m { 7.3 to 10.9 kgf・m / 52.7 to 78.9 lb・ft } |

71.6 to 107.0 N・m { 7.3 to 10.9 kgf・m / 52.8 to 78.9 lb・ft } |

79.5 to 119.0 N・m { 8.1 to 12.1 kgf・m / 58.6 to 87.8 lb・ft } |

| M14 x 1.5 |

106.0 to 159.0 N・m { 10.8 to 16.2 kgf・m / 78.2 to 117.3 lb・ft } |

115.0 to 172.0 N・m { 11.7 to 17.5 kgf・m / 84.8 to 126.9 lb・ft } |

114.0 to 171.0 N・m { 11.6 to 17.4 kgf・m / 84.1 to 126.1 lb・ft } |

123.0 to 185.0 N・m { 12.5 to 18.9 kgf・m / 90.7 to 136.4 lb・ft } |

| *M14 x 2 |

101.0 to 150.0 N・m { 10.3 to 15.3 kgf・m / 74.5 to 110.6 lb・ft } |

108.0 to 162.0 N・m { 11.0 to 16.5 kgf・m / 79.7 to 119.5 lb・ft } |

107.0 to 160.0 N・m { 10.9 to 16.3 kgf・m / 78.9 to 118.0 lb・ft } |

116.0 to 173.0 N・m { 11.8 to 17.6 kgf・m / 85.6 to 127.6 lb・ft } |

| M16 x 1.5 |

154.0 to 233.0 N・m { 15.7 to 23.8 kgf・m / 113.6 to 171.9 lb・ft } |

171.0 to 257.0 N・m { 17.4 to 26.2 kgf・m / 126.1 to 189.6 lb・ft } |

160.0 to 240.0 N・m { 16.3 to 24.5 kgf・m / 118.0 to 177.0 lb・ft } |

177.0 to 265.0 N・m { 18.0 to 27.0 kgf・m / 130.5 to 195.5 lb・ft } |

| *M16 x 2 |

148.0 to 221.0 N・m { 15.1 to 22.5 kgf・m / 109.2 to 163.0 lb・ft } |

163.0 to 244.0 N・m { 16.6 to 24.9 kgf・m / 120.2 to 180.0 lb・ft } |

153.0 to 230.0 N・m { 15.6 to 23.5 kgf・m / 112.8 to 169.6 lb・ft } |

169.0 to 253.0 N・m { 17.2 to 25.8 kgf・m / 124.6 to 186.6 lb・ft } |

| M18 x 1.5 |

246.0 to 368.0 N・m { 25.1 to 37.5 kgf・m / 181.4 to 271.4 lb・ft } |

- |

254.0 to 380.0 N・m { 25.9 to 38.7 kgf・m / 187.3 to 280.3 lb・ft } |

- |

| *M18 x 2.5 |

224.0 to 335.0 N・m { 22.8 to 34.2 kgf・m / 165.2 to 247.1 lb・ft } |

- |

231.0 to 346.0 N・m { 23.6 to 35.3 kgf・m / 170.4 to 255.2 lb・ft } |

- |

| M20 x 1.5 |

307.0 to 462.0 N・m { 31.3 to 47.1 kgf・m / 226.4 to 340.8 lb・ft } |

- |

317.0 to 476.0 N・m { 32.3 to 48.5 kgf・m / 233.8 to 351.1 lb・ft } |

- |

| *M20 x 2.5 |

284.0 to 427.0 N・m { 29.0 to 43.5 kgf・m / 209.5 to 314.9 lb・ft } |

- |

293.0 to 440.0 N・m { 29.9 to 44.9 kgf・m / 216.1 to 324.5 lb・ft } |

- |

| M22 x 1.5 |

414.0 to 621.0 N・m { 42.2 to 63.3 kgf・m / 305.3 to 458.0 lb・ft } |

- |

425.0 to 637.0 N・m { 43.3 to 65.0 kgf・m / 313.5 to 469.8 lb・ft } |

- |

| *M22 x 2.5 |

386.0 to 578.0 N・m { 39.4 to 58.9 kgf・m / 284.7 to 426.3 lb・ft } |

- |

394.0 to 592.0 N・m { 40.2 to 60.4 kgf・m / 290.6 to 436.6 lb・ft } |

- |

| M24 x 2 |

491.0 to 811.0 N・m { 50.1 to 82.7 kgf・m / 362.1 to 598.2 lb・ft } |

- |

554.0 to 831.0 N・m { 56.5 to 84.7 kgf・m / 408.6 to 612.9 lb・ft } |

- |

| *M24 x 3 |

463.0 to 693.0 N・m { 47.2 to 70.7 kgf・m / 341.5 to 511.1 lb・ft } |

- |

521.0 to 782.0 N・m { 53.1 to 79.7 kgf・m / 384.3 to 576.8 lb・ft } |

- |

Note

- Those indicated with an asterisk (*) are used for the internal threaded portion of soft material such as castings.

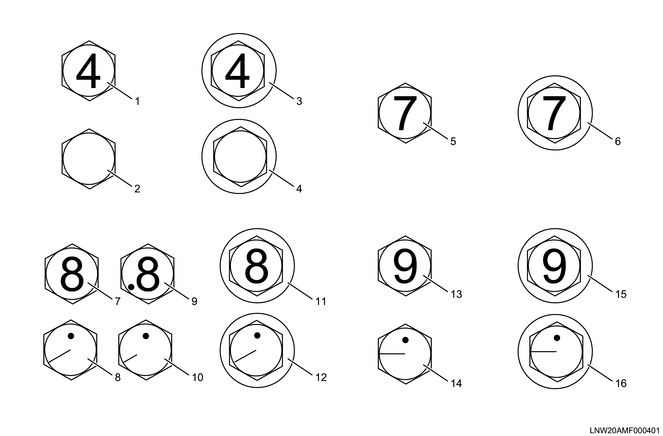

- Refer to the following list for the indicators used on standard bolt heads.

Display on head of standard bolt

Legend

- Hex bolt (4.8, 4T)

- Hex bolt (4.8, 4T)

- Flange bolt (4.8, 4T)

- Flange bolt (4.8, 4T)

- Hex bolt (7T)

- Flange bolt (7T)

- Hex bolt (Thermally refined 8.8)

- Hex bolt (Thermally refined 8.8)

- Hex bolt (Non-thermally refined 8.8)

- Hex bolt (Non-thermally refined 8.8)

- Flange bolt (8.8)

- Flange bolt (8.8)

- Hex bolt (9.8, 9T)

- Hex bolt (9.8, 9T)

- Flange bolt (9.8, 9T)

- Flange bolt (9.8, 9T)

2. Tightening torque for flare nuts

| Pipe diameter |

HEX |

Nominal designation of thread |

Tightening torque |

| 4.76 mm { 0.19 in } |

10 mm |

M10 x 1.0 |

13 to 18 N・m { 1.3 to 1.8 kgf・m / 115 to 159 lb・in } Iron |

| 9 to 15 N・m { 0.9 to 1.5 kgf・m / 80 to 133 lb・in } Non-ferrous |

|||

| 6.35 mm { 0.25 in } |

12 mm |

M12 x 1.0 |

25 to 35 N・m { 2.5 to 3.6 kgf・m / 18 to 26 lb・ft } Iron |

| 8.0 mm { 0.31 in } |

14 mm |

M14 x 1.5 |

29 to 39 N・m { 3.0 to 4.0 kgf・m / 21 to 29 lb・ft } Iron |

| 10.0 mm { 0.39 in } |

17 mm |

M16 x 1.5 |

45 to 55 N・m { 4.6 to 5.6 kgf・m / 33 to 41 lb・ft } Iron |

| Pipe diameter |

HEX |

Nominal designation of thread |

Tightening torque* |

| 4.76 mm { 0.19 in } |

14 mm |

M10 x 1.0 |

13 to 18 N・m { 1.3 to 1.8 kgf・m / 115 to 159 lb・in } Iron |

| 6.35 mm { 0.25 in } |

17 mm |

M12 x 1.5 |

25 to 35 N・m { 2.5 to 3.6 kgf・m / 18 to 26 lb・ft } Iron |

| 19.6 to 23.5 N・m { 2.0 to 2.4 kgf・m / 14 to 17 lb・ft } Non-ferrous |

|||

| 8.0 mm { 0.31 in } |

17 mm |

M14 x 1.5 |

25 to 39 N・m { 2.5 to 4.0 kgf・m / 18 to 29 lb・ft } Iron |

| 19.6 to 23.5 N・m { 2.0 to 2.4 kgf・m / 14 to 17 lb・ft } Non-ferrous |

|||

| 10.0 mm { 0.39 in } |

19 mm |

M16 x 1.5 |

45 to 80 N・m { 4.6 to 8.2 kgf・m / 33 to 59 lb・ft } Iron |

| 39.2 to 44.1 N・m { 4.0 to 4.5 kgf・m / 29 to 33 lb・ft } Non-ferrous |

|||

| 12.0 mm { 0.47 in } |

24 mm |

M16 x 1.5 |

65 to 115 N・m { 6.6 to 11.7 kgf・m / 48 to 85 lb・ft } Iron |

| 49.0 to 58.8 N・m { 5.0 to 6.0 kgf・m / 36 to 43 lb・ft } Non-ferrous |

|||

| 15.0 mm { 0.59 in } |

30 mm |

M22 x 1.5 |

80 to 130 N・m { 8.2 to 13.3 kgf・m / 59 to 96 lb・ft } Iron |

| 49.0 to 58.8 N・m { 5.0 to 6.0 kgf・m / 36 to 43 lb・ft } Non-ferrous |

Note

- Asterisks (*) indicate that the tightening torque varies depending on the material of the opposing side. Non-ferrous: Aluminum and brass

3. Tightening torques for PT screws and connectors

Caution

- Apply a liquid sealing agent equivalent to LOCTITE 575 to the threaded portion and tighten. Do not use seal tape, etc.

- The tightening torque for connectors (except brass tapered screws) only applies when the mating side is not made of aluminum (however, it does apply for aluminum air tanks, etc.).

- Completely dry and then let air in after tightening.

| Nominal designation of thread |

Tightening torque |

| PT(R)1/8 |

2.0 to 14.7 N・m { 0.2 to 1.5 kgf・m / 18 to 130 lb・in } |

| PT(R)1/4 |

4.9 to 15.7 N・m { 0.5 to 1.6 kgf・m / 43 to 139 lb・in } |

| PT(R)3/8 |

9.8 to 16.7 N・m { 1.0 to 1.7 kgf・m / 87 to 148 lb・in } |

| PT(R)1/2 |

9.8 to 17.7 N・m { 1.0 to 1.8 kgf・m / 87 to 157 lb・in } |

| Nominal designation of thread |

Tightening torque |

| PT(R)1/8 |

5.9 to 11.8 N・m { 0.6 to 1.2 kgf・m / 52 to 104 lb・in } |

| PT(R)1/4 |

14.7 to 29.4 N・m { 1.5 to 3.0 kgf・m / 130 to 260 lb・in } |

| PT(R)3/8 |

29.4 to 39.2 N・m { 3.0 to 4.0 kgf・m / 22 to 29 lb・ft } |

| PT(R)1/2 |

29.4 to 58.8 N・m { 3.0 to 6.0 kgf・m / 22 to 43 lb・ft } |

| PT(R)3/4 |

58.8 to 98.0 N・m { 6.0 to 10.0 kgf・m / 43 to 72 lb・ft } |

| Nominal designation of thread |

Tightening torque |

|

| Brass tapered screws |

Except brass tapered screws |

|

| PT 1/8 |

2.0 N・m { 0.2 kgf・m / 18 lb・in } |

5.9 N・m { 0.6 kgf・m / 52 lb・in } |

| PT 1/4 |

4.9 N・m { 0.5 kgf・m / 43 lb・in } |

14.7 N・m { 1.5 kgf・m / 130 lb・in } |

| PT 3/8 |

9.8 N・m { 1.0 kgf・m / 87 lb・in } |

29.4 N・m { 3.0 kgf・m / 22 lb・ft } |

| PT 1/2 |

9.8 N・m { 1.0 kgf・m / 87 lb・in } |

29.4 N・m { 3.0 kgf・m / 22 lb・ft } |

| PT 3/4 |

- |

58.8 N・m { 6.0 kgf・m / 43 lb・ft } |

Caution

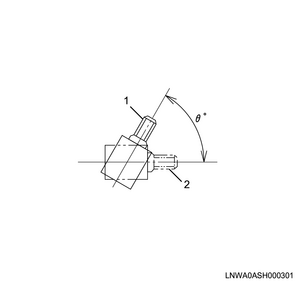

- For elbow-type connectors, tighten to the torque in the above table, and then further tighten until the angle is in the correct position.

Legend

- Specified lowest torque position

- Correct position