1. Coolant safety information

Warning

- Inspection, refilling, and replacement should be performed when the engine has cooled sufficiently.

- Do not loosen the radiator cap or reserve tank cap when coolant is hot, as doing so may result in burns caused by the release of steam or hot water.

- When opening the radiator cap or reserve tank cap, place a thick cloth over the cap after the coolant has cooled, and turn it slowly to release the pressure before removing it.

- Do not drink the coolant as it is poisonous.

If accidentally swallowed, immediately induce vomiting and seek the advice of a doctor. - If coolant has gotten in your eyes, immediately flush it out with running water for 15 minutes or more.

Seek the advice of a doctor if there is any irritation, etc. - If any coolant has gotten on your skin, wash it away with large amounts of water and soap.

Seek the advice of a doctor if there are any complications. - When storing, seal tightly and keep in a location out of reach of children.

- Keep coolant away from flames as it is flammable.

Caution

- In order to prevent damage to the engine due to freezing of the coolant as well as to protect the cooling system from corrosion, mix the specified coolant and water to a concentration of 50% each.

- Rustproof ability declines with a coolant concentration of 30% or less.

- Overheat possibility arises with a coolant concentration of 60% or more.

- If coolant with a concentration other than that specified is used, anti-freezing performance may decrease, causing freezing to occur.

- Do not use a coolant other than genuine Isuzu coolant.

- If the vehicle or engine is used in a cold area at -30°C {-22°F}, use an engine coolant with 55% concentration.

2. Coolant inspection

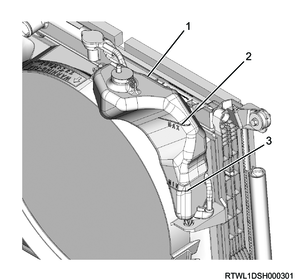

1. Engine coolant level inspection

1) Inspect the engine coolant level in the radiator reserve tank, and verify that it is between the MAX line and the MIN line.

2) Open the radiator cap and verify that the engine coolant is added to the filler section in the radiator.

Caution

- Inspect the engine coolant level when the engine is cold.

3) When the engine coolant level is low, remove the reserve tank cap and add engine coolant to near the MAX line.

Legend

- Radiator reserve tank

- MAX line

- MIN line

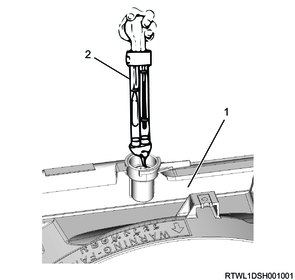

2. Coolant concentration inspection (Hydrometry method)

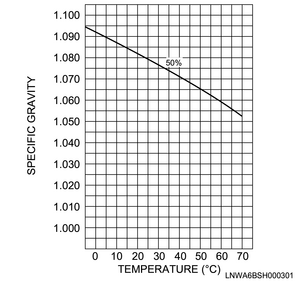

1) Measure the specific gravity and coolant temperature using a hydrometer to obtain the concentration from the table.

Caution

- Measure the temperature of the engine coolant within the range of 0°C {32°F} to 50°C {122°F}.

- Use a container that has a depth greater than the length of the hydrometer.

Legend

- Radiator

- Hydrometer

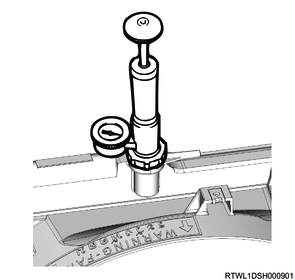

3. Coolant concentration inspection (Coolant scope method)

1) Measure the concentration using a coolant scope.

3. Radiator cap inspection

1. Visual inspection

1) Inspect the radiator cap for the following.

- Excessive wear

- Damage

Note

- Adjust, repair, or replace the radiator cap if any abnormal conditions are found.

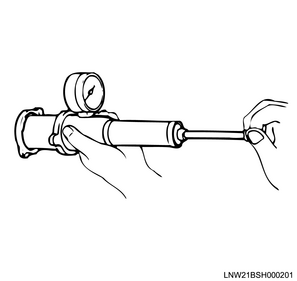

2. Radiator cap opening valve pressure measurement

1) Measure the valve opening pressure of the pressurizing valve using the special tool.

Standard: 93.3 to 122.7 kPa { 1.0 to 1.3 kgf/cm2 / 13.5 to 17.8 psi }

Note

- If the measured value is outside the standard range, replace the radiator cap.

SST: 5-8840-0277-0 - radiator cap tester

SST: 5-8840-2603-0 - adapter

2) Inspect the vacuum valve located in the center of the valve seat side of the radiator cap for abnormal conditions.

Note

- If there is rust or fouling, or the valve seat cannot be moved by hand, clean or replace the radiator cap.

3) Measure the radiator cap open valve pressure using the special tool.

Standard: -1.96 to 4.91 kPa { -0.0 to 0.1 kgf/cm2 / -0.3 to 0.7 psi }

4. Coolant vehicle inspection

1) Inspect for engine coolant leakage from the following parts using a radiator cap tester.

- Radiator

- Water pump

- Radiator upper hose

- Radiator lower hose

- Water pipe

- Water rubber hose

- Radiator reserve tank

196 kPa { 2.0 kgf/cm2 / 28 psi } Specified pressure