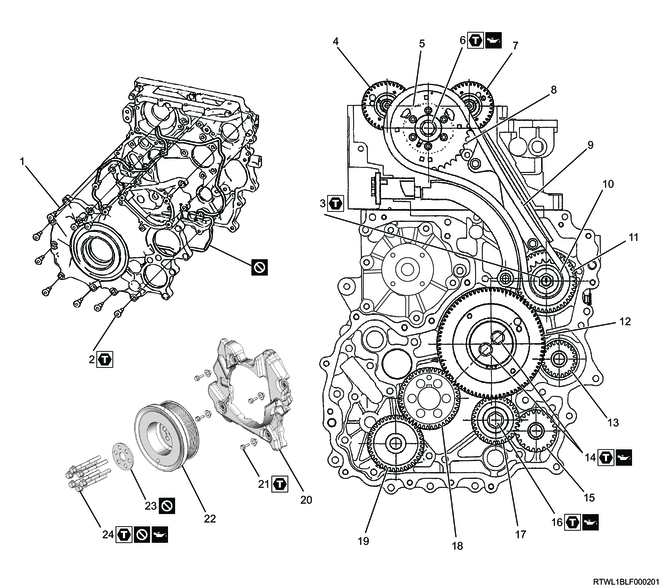

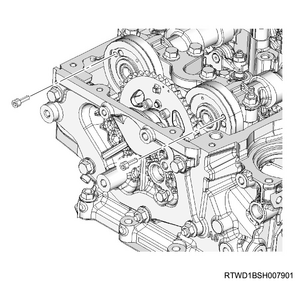

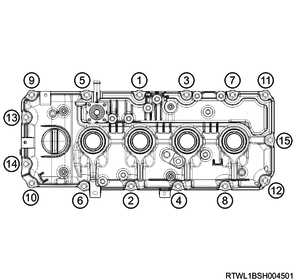

1. Component views

Idle gear

Part name

- Gear case cover

- Bolt

- Supply pump gear nut

- Exhaust camshaft gear

- Idle gear D

- Idle gear D shaft bolt

- Inlet camshaft gear

- Idle gear D sprocket

- Timing chain

- Supply pump sprocket

- Supply pump gear

- Idle gear A

- Vacuum pump gear

- Idle gear A bolt

- Power steering oil pump gear

- Idle gear C bolt

- Idle gear C

- Crankshaft gear

- Oil pump gear

- Cover

- Bolt

- Crankshaft pulley

- Washer

- Bolt

Tightening torque

2: 8.0 N・m { 0.8 kgf・m / 71 lb・in }

3: 130 N・m { 13.3 kgf・m / 96 lb・ft }

6: 59 N・m { 6.0 kgf・m / 44 lb・ft }

14: 32 N・m { 3.3 kgf・m / 24 lb・ft }

16: 59 N・m { 6.0 kgf・m / 44 lb・ft }

21: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

24-1: 30 N・m { 3.1 kgf・m / 22 lb・ft }

24-2: 180 °

24-3: 60 °

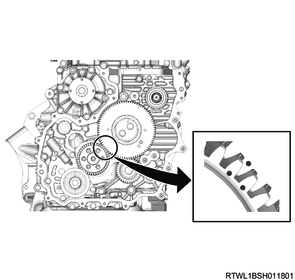

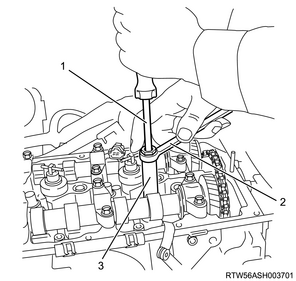

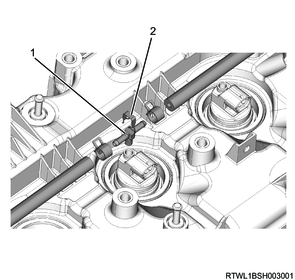

2. Idle gear installation

1) Apply engine oil to the sliding surface of the idle gear D shaft and idle gear inner surface.

2) Install the idle gear D shaft to the camshaft brackets.

3) Install idle gear D to the idle gear shaft.

Note

- Tightening of the idle gear D shaft bolt should be performed after the timing chain is installed.

Legend

- Idle gear D

- Idle gear D shaft

- Camshaft bracket

4) Apply engine oil to the gear assembly sections of the idle gear C shaft.

5) Install the idle gear C shaft to the timing gear case.

6) Apply engine oil to the threaded portion and seating surface of the idle gear C bolt.

7) Temporarily tighten idle gear C to the idle gear C shaft.

Caution

- Install so that the pink paint can be seen.

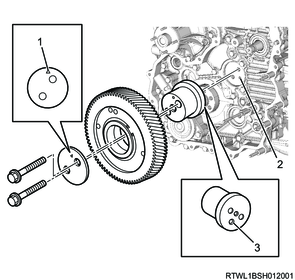

8) Apply engine oil to the idle gear A shaft.

9) Install the idle gear A shaft to the timing gear case by aligning the cylinder block side oil hole with the idle gear A shaft oil hole.

Legend

- Front mark

- Cylinder block side oil hole

- Idle gear A shaft oil hole

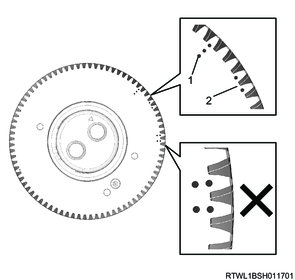

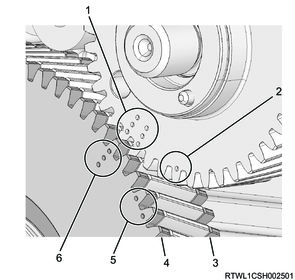

10) Install idle gear A to the idle gear A shaft.

Caution

- Do not align the 4 circular marks of idle gear A shown in the following diagram with the marks of the supply pump gear.

Legend

- Supply pump installation or removal position (Idle gear A side)

- TDC position (Idle gear A side)

11) Apply engine oil to the tooth surface of idle gear A.

12) Install the flange to idle gear A with the front mark facing toward the front.

13) Apply engine oil to the threaded portions and seating surfaces of the bolts, and then temporarily tighten the bolts.

14) Install the crank gear to the crankshaft.

Note

- Install after aligning with the idle gear alignment marks.

15) Final tighten idle gear A to the idle gear A shaft.

Tightening torque: 32 N・m { 3.3 kgf・m / 24 lb・ft }

16) Final tighten idle gear C to the idle gear C shaft.

Tightening torque: 59 N・m { 6.0 kgf・m / 44 lb・ft }

Legend

- Idle gear A bolt

- Idle gear C bolt

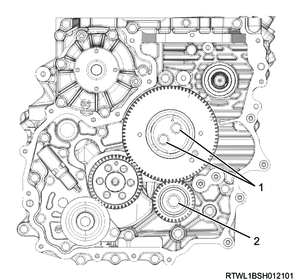

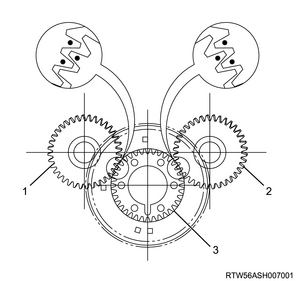

3. Supply pump gear installation

1) Align 3 marks on the supply pump gear and idle gear A, and install the supply pump gear to the supply pump shaft.

Caution

- Check that the supply pump gear is securely engaged with the main and sub gears of idle gear A.

Legend

- Supply pump installation or removal position (Supply pump gear side)

- TDC position (Supply pump gear side)

- Sub-gear

- Sub-gear

- TDC position (Idle gear A side)

- Supply pump installation or removal position (Idle gear A side)

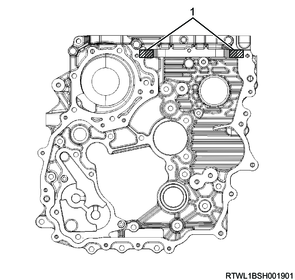

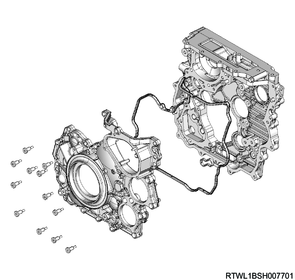

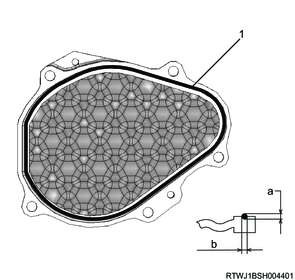

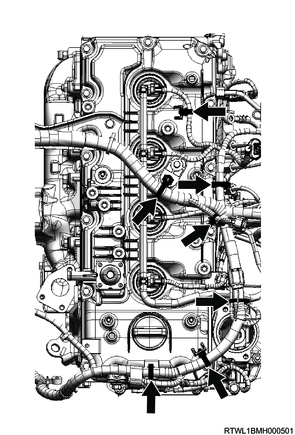

4. Gear case cover installation

1) Referring to the diagram, apply ThreeBond 1207B to the timing gear case.

Caution

- Install the gear case cover within 5 minutes of applying liquid gasket.

Legend

- Liquid gasket application area

2) Install the gasket to the gear case cover.

Caution

- Do not reuse the gasket.

3) Install the gear case cover to the timing gear case.

Tightening torque: 8.0 N・m { 0.8 kgf・m / 71 lb・in }

4) Install the cover to the gear case cover.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

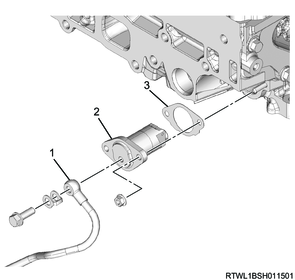

5. Vacuum pump installation

1) Install the vacuum pump to the gear case cover.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

2) Install the vacuum pump oil pipe to the vacuum pump and cylinder block.

Tightening torque: 12 N・m { 1.2 kgf・m / 106 lb・in }

3) Install the vacuum pipe as a set with the vacuum hose to the timing gear case and vacuum pump.

Tightening torque: 32 N・m { 3.3 kgf・m / 24 lb・ft } Vacuum pump side

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft } Timing gear case side

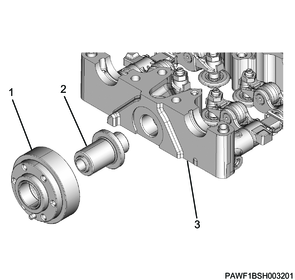

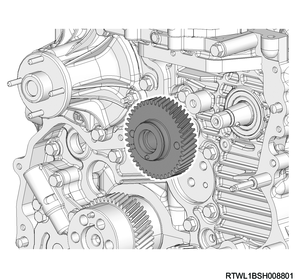

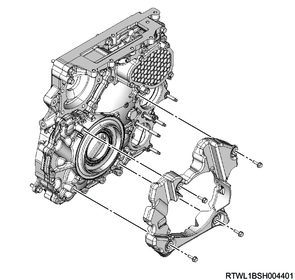

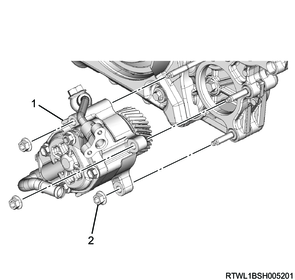

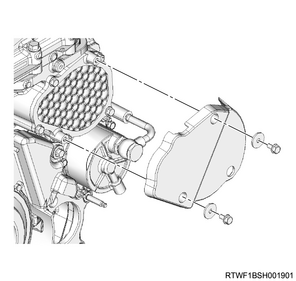

6. Power steering oil pump connect

1) Install the power steering oil pump to the timing gear case.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

Legend

- Power steering oil pump

- Nut

2) Install the power steering oil hose to the bracket.

Legend

- Bracket

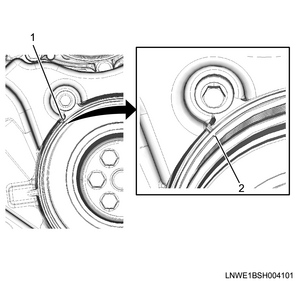

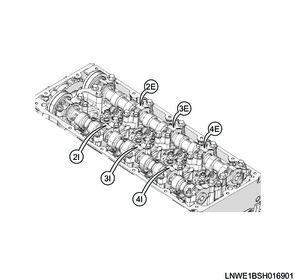

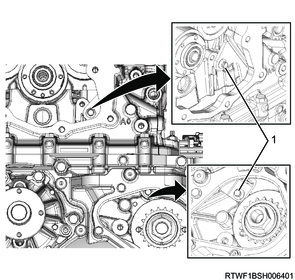

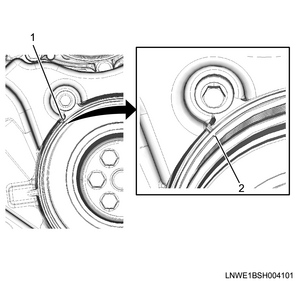

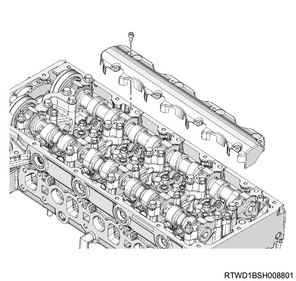

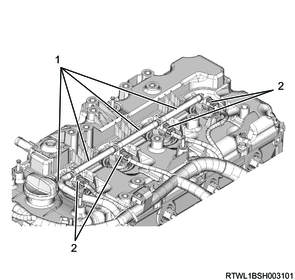

7. Camshaft installation

1) Rotate the crankshaft in the forward direction (clockwise) to align the No. 1 cylinder piston to compression top dead center.

Legend

- Top dead center alignment mark on the gear case cover side

- Crankshaft pulley side top dead center alignment mark

2) Apply the engine oil to the camshaft journal.

3) Install the camshaft to the camshaft brackets with the inlet camshaft and exhaust camshaft markings upward.

Caution

- Check the marking on the camshaft upper bracket.

4) Align the camshaft timing marks with idle gear D.

Caution

- Loosen the rocker arm adjust nut in advance and loosen the adjust screw by 2 pitch or more.

Legend

- Exhaust camshaft gear

- Inlet camshaft gear

- Idle gear D

5) Apply engine oil to the following parts.

- Camshaft upper bracket sliding surface

- Camshaft journal

- Threaded portion and seating surface of bolts

6) Align the inlet camshaft and exhaust camshaft alignment marks with the camshaft upper bracket.

Caution

- Confirm that the valve cap is correctly installed to the valve stem end.

- Check that the valve cap does not come off or ride up.

Legend

- Alignment mark

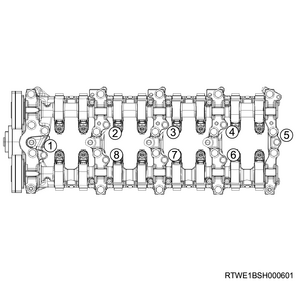

7) Temporarily tighten the camshaft upper bracket M8 bolts to the cylinder head in the order shown in the diagram.

Caution

- Check the marking on the top surface.

8) Final tighten the camshaft upper bracket M8 bolts to the cylinder head in the order shown in the diagram.

Tightening torque: 18 N・m { 1.8 kgf・m / 13 lb・ft } Wet

9) Temporarily tighten the camshaft upper bracket M6 bolts to the camshaft brackets in the order shown in the diagram.

10) Final tighten the camshaft upper bracket M6 bolts to the camshaft brackets in the order shown in the diagram.

Tightening torque: 7.0 N・m { 0.7 kgf・m / 62 lb・in } Dry

Tightening torque: 6.0 N・m { 0.6 kgf・m / 53 lb・in } Wet

11) Remove the lock bolt from the camshaft gear.

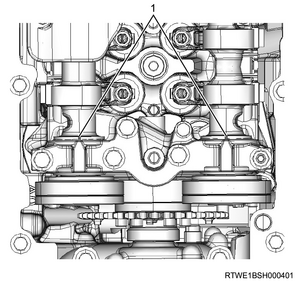

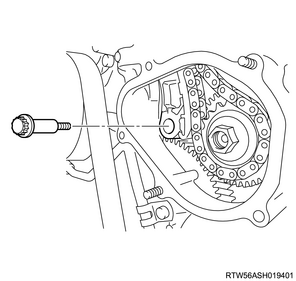

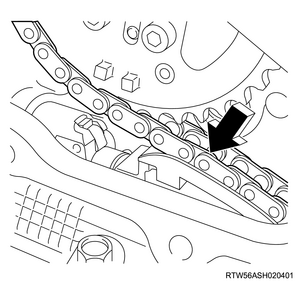

8. Timing chain installation

1) Install the timing chain guide to the cylinder head and cylinder block.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

Legend

- Timing chain guide bolt

2) Insert the timing chain tension lever into the gap between the timing gear case and the cylinder block.

3) Align the timing chain with the supply pump sprocket.

4) Install the sprocket and timing chain as a set to idle gear D.

Tightening torque: 8.0 N・m { 0.8 kgf・m / 71 lb・in }

5) Apply engine oil to the threaded portion and seating surface of the idle gear D shaft bolt.

6) Install the idle gear D shaft bolt and sleeve to idle gear D and sprocket.

Tightening torque: 59 N・m { 6.0 kgf・m / 44 lb・ft }

7) Align the 2 timing alignment marks at the location shown in the diagram.

Legend

- Timing chain

- Timing mark

- Blue link

- Yellow link

8) Install the timing chain lever pivot to the timing chain tension lever.

Tightening torque: 27 N・m { 2.8 kgf・m / 20 lb・ft }

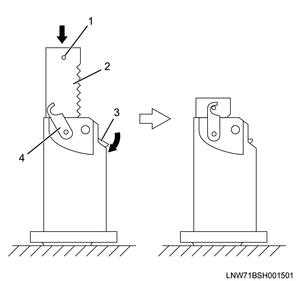

9) Push down the timing chain tensioner latch and insert the plunger.

Note

- Install the hook to the pin while pressing the plunger.

Legend

- Pin

- Plunger

- Latch

- Hook

10) Install the timing chain tensioner and gasket to the cylinder head.

Caution

- Do not reuse the gasket.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

11) Install the oil feed pipe to the timing chain tensioner.

Caution

- Do not reuse the gasket.

Tightening torque: 14.7 N・m { 1.5 kgf・m / 130 lb・in }

Legend

- Oil feed pipe

- Timing chain tensioner

- Gasket

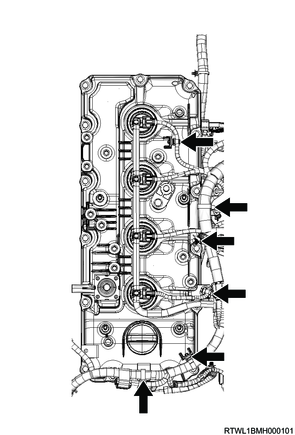

12) Lightly press the area indicated by the arrow in the diagram to disconnect the hook from the pin.

Note

- The hook of the tensioner opens and the plunger pushes the tension lever to pull the chain.

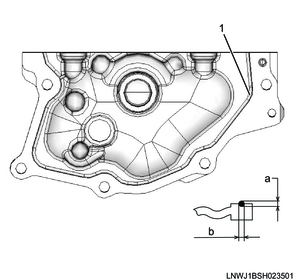

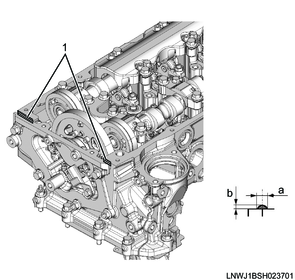

9. Timing chain upper cover installation

1) Referring to the diagram, apply ThreeBond 1207C or equivalent to the timing chain upper cover.

Caution

- Install the timing chain cover within 5 minutes of applying the liquid gasket.

Legend

- Liquid gasket

Standard value

a: 1.0 to 1.5 mm { 0.039 to 0.059 in } Bead height

b: 2.0 to 2.5 mm { 0.079 to 0.098 in } Bead width

2) Install the timing chain upper cover to the cylinder head.

Caution

- Wipe off any excess liquid gasket.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

3) Connect the connector to the CMP sensor.

10. Tension pulley installation

1) Install the tension pulley to the cylinder head.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

11. Timing chain lower cover installation

1) Referring to the diagram, apply ThreeBond 1207C or equivalent to the timing chain lower cover.

Legend

- Liquid gasket

Standard value

a: 2.0 to 2.5 mm { 0.079 to 0.098 in } Bead height

b: 2.0 to 2.5 mm { 0.079 to 0.098 in } Bead width

2) Install the timing chain lower cover to the gear case cover.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

3) Install the noise cover to the timing chain lower cover.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

12. Rocker arm adjustment

1) Rotate the crankshaft in the forward direction (clockwise) to align the No. 1 cylinder piston to compression top dead center.

Legend

- Top dead center alignment mark on the gear case cover side

- Crankshaft pulley side top dead center alignment mark

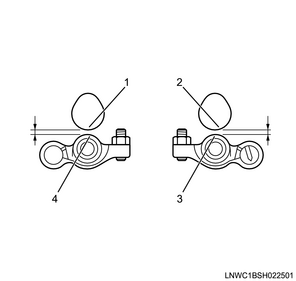

2) Loosen the adjust screw of the rocker arm using the special tool.

SST: 5-8840-2822-0 - valve clearance adjust nut wrench

Legend

- Screwdriver

- Ring spanner

- 5-8840-2822-0

3) Insert a feeler gauge between the rocker arm roller and the cam.

Note

- Tighten the rocker arm adjust screw, and adjust the valve clearance to the standard value.

Standard: 0.15 mm { 0.0059 in } When cold

4) Lightly tighten the adjust screw with the feeler gauge inserted using the special tool.

Legend

- Cam (Exhaust side)

- Cam (Inlet side)

- Roller (Inlet side)

- Roller (Exhaust side)

5) Verify that the movement of the feeler gauge becomes stiff.

6) Secure the rocker arm adjust screw with the adjust screw nut.

Tightening torque: 18 N・m { 1.8 kgf・m / 13 lb・ft }

| Cylinder position |

#1 |

#2 |

#3 |

#4 |

||||

| IN |

EX |

IN |

EX |

IN |

EX |

IN |

EX |

|

| No. 1 cylinder compression top dead center |

○ |

○ |

○ |

○ |

||||

| No. 4 cylinder compression top dead center |

○ |

○ |

○ |

○ |

||||

7) Rotate the crankshaft for 1 turn, and adjust any remaining valve clearance.

13. Baffle plate installation

1) Install the baffle plate to the cylinder head.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

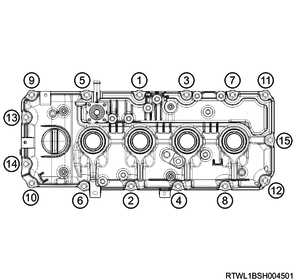

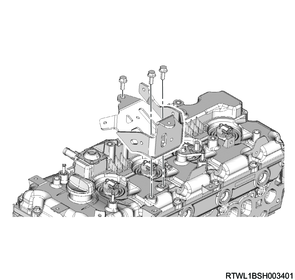

14. Cylinder head cover installation

1) Apply the engine oil to the oil seal.

2) Insert the oil seal from the lower side of the cylinder head cover until it reaches the far end.

3) Referring to the diagram, apply ThreeBond 1217H or 1207C to the cylinder head mating surface.

Caution

- Install the cylinder head cover within 5 minutes of applying liquid gasket.

- Remove any dirt or dust from the oil seal section on the injector connector side.

Legend

- Liquid gasket

Standard value

a: 2.0 to 2.5 mm { 0.079 to 0.098 in } Bead width

b: 1.0 to 1.5 mm { 0.039 to 0.059 in } Bead height

4) Temporarily tighten the cylinder head cover to the cylinder head in the order shown in the diagram.

Caution

- Do not reuse the gasket.

Tightening torque: 5.0 N・m { 0.5 kgf・m / 44 lb・in }

5) Final tighten the cylinder head cover to the cylinder head in the order shown in the diagram.

Tightening torque: 9.0 N・m { 0.9 kgf・m / 80 lb・in }

6) Install the harness bracket to the cylinder head cover.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

7) Connect the harness clip to the cylinder head cover.

RHD

LHD

8) Connect the PCV hose to the cylinder head cover.

15. Fuel leak-off hose installation

1) Install the injector leak-off pipe to the injector.

Caution

- Do not reuse the injector leak-off pipe or clip.

Legend

- Injector leak-off pipe

- Clip

2) Install the fuel leak-off hose to the leak-off pipe.

3) Connect the connector to the injector.

Legend

- Fuel leak-off hose

- Injector connector

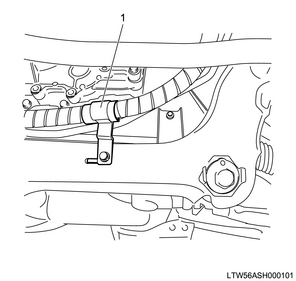

16. Air duct bracket installation

1) Install the air duct bracket to the cylinder head cover.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

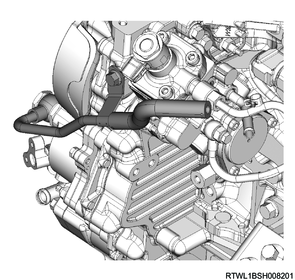

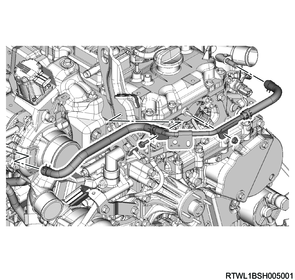

17. Water pipe installation

1) Install the water pipe to the following parts.

- Thermostat

- Cylinder head

- Turbocharger

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in } Bolt, nut

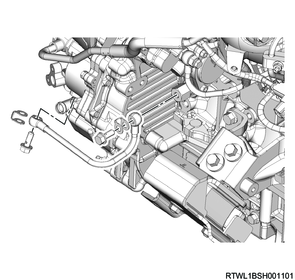

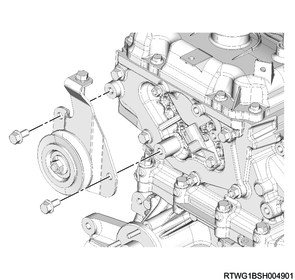

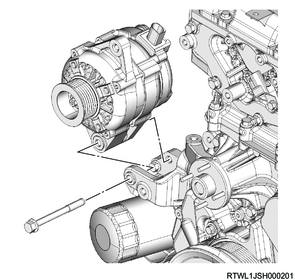

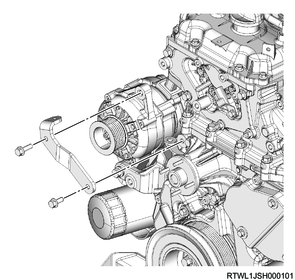

18. Generator installation

1) Install the generator to the lower bracket.

Tightening torque: 40 N・m { 4.1 kgf・m / 30 lb・ft }

2) Install the upper bracket to the generator and timing gear case.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

3) Connect the connector to the generator.

4) Connect the B-terminal to the generator.

Tightening torque: 12 N・m { 1.2 kgf・m / 106 lb・in }