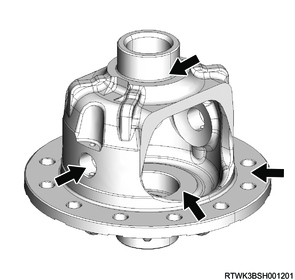

1. Final drive inspection

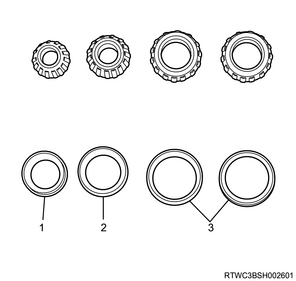

1) Inspect each bearing for the following.

- Seizing

- Spalling

- Noise

Legend

- Inner bearing

- Outer bearing

- Side bearing

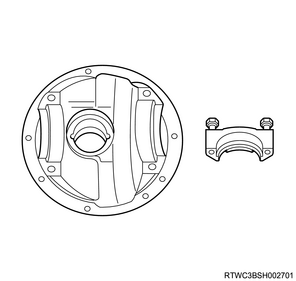

2) Inspect the differential carrier rear axle mounting section, differential carrier side bearing mounting section, as well as bearing cap for the following.

- Cracking

- Damage

- Wear

3) Inspect the pinion bearing race and pinion bearing oil seal inlay sections for the following.

- Cracking

- Damage

- Wear

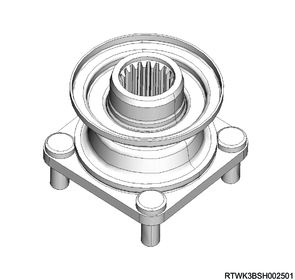

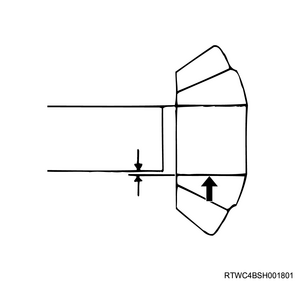

4) Inspect the flange for the following.

- Worn oil seal contact section

- Worn spline section

- Cracking of mounting section

- Damage to the mounting section

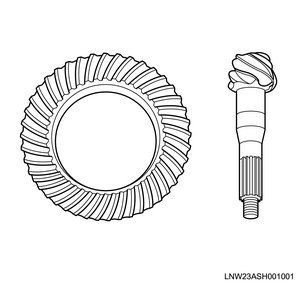

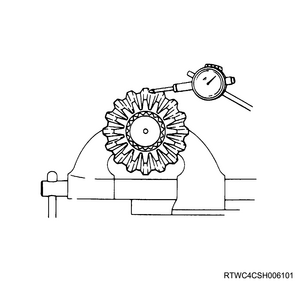

5) Inspect the gear contact surfaces on the drive and coast sides of the ring gear and drive pinion for the following.

- Chipping

- Cracking

- Spalling

- Pitting

- Improper tooth contact

6) Inspect the spline section of the drive pinion for the following.

- Cracking

- Twisting

- Damage

Caution

- Replace the ring gear and drive pinion as a set.

2. Differential cage inspection

1. Visual inspection

1) Inspect the side gear, side gear thrust washer, pinion gear, and cross pin for the following.

- Wear

- Damage

- Other malfunctions

2) Inspect the differential cage for the following.

- Wear

- Damage

- Corrosion

- Other malfunctions

3) Inspect the fitting section of the differential cage and ring gear, the fitting section of the differential cage and side gear, as well as the differential cage cross pin holes for the following.

- Damage

- Wear

Note

- Repair minor damage and wear using an oil stone or fine sandpaper.

2. Pinion gear measurement

1) Measure the outer diameter of the cross pin using a micrometer.

2) Measure the inner diameter of the pinion gear.

3) Calculate the clearance between the pinion gear and cross pin from the outer diameter of the cross pin and the inner diameter of the pinion gear.

Standard: 0.06 to 0.12 mm { 0.002 to 0.005 in }

Limit: 0.20 mm { 0.008 in }

3. Side gear measurement

1) Install the side gear to the drive shaft.

2) Measure the play of the side gear and drive shaft in the spline rotational direction using a dial gauge.

Standard: 0.08 to 0.38 mm { 0.003 to 0.015 in }

Limit: 0.5 mm { 0.02 in }

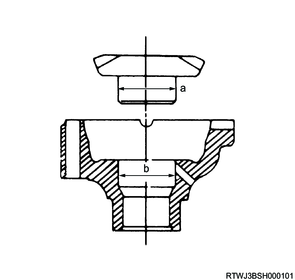

4. Differential cage measurement

1) Measure the outer diameter of the side gear using a micrometer.

2) Measure the inner diameter of the differential cage using a cylinder gauge.

3) Calculate the clearance of the side gear and differential cage from the outer diameter of the side gear and the inner diameter of the differential cage.

Standard: 0.05 to 0.11 mm { 0.002 to 0.004 in }

Limit: 0.15 mm { 0.006 in }

Legend

a. Side gear outer diameter

b. Differential cage inner diameter