1. Turbocharger inspection

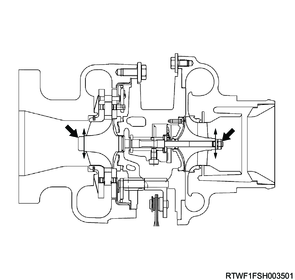

1. Wheel shaft play measurement

1) Measure the wheel shaft end play using a dial gauge when a load is applied to both sides of the compressor wheel.

Standard: 12 N { 1.2 kg / 2.7 lb } Load

Standard: 0.03 to 0.08 mm { 0.0012 to 0.0031 in }

Limit: 0.09 mm { 0.0035 in }

2. Clearance measurement between wheel shaft and bearing

1) Measure the clearance between the wheel shaft and the bearing by moving the impeller end section.

Standard: 0.06 to 0.10 mm { 0.0024 to 0.0039 in }

Limit: 0.13 mm { 0.0051 in }

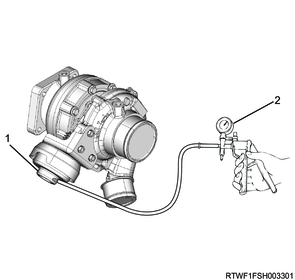

3. Actuator operation inspection

1) Install the vacuum pump to the actuator.

Legend

- Actuator

- Vacuum pump

2) When the vacuum is applied to the actuator, check that the lever makes contact with the stopper.

3) Apply the standard pressure for 30 seconds and check that the vacuum does not decrease.

Standard: -50 kPa { -0.5 kgf/cm2 / -7 psi }

4) Place the vernier caliper at the control rod end of the actuator.

5) Gradually release the negative pressure and verify that the control rod moves smoothly.

6) Check the length of the control rod when the lever makes contact with the stopper after releasing the vacuum.

Standard: 14.4 mm { 0.567 in }