1. Front propeller shaft inspection

1. Visual inspection

1) Inspect the spider for the following.

- Wear

- Damage

- Other malfunctions

2) Inspect the needle roller bearing for the following.

- Wear

- Damage

- Other malfunctions

3) Inspect the flange yoke for the following.

- Wear

- Damage

- Other malfunctions

4) Inspect the flange for the following.

- Wear

- Damage

- Other malfunctions

5) Inspect the seal for the following.

- Wear

- Damage

- Other malfunctions

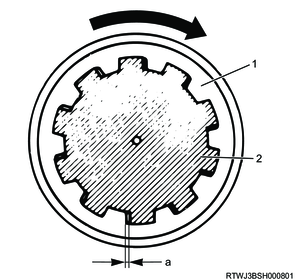

2. Spline yoke measurement

1) Install the spline yoke to the propeller shaft.

2) Measure the play in the rotational direction of the sleeve yoke and spline yoke using a tapered feeler gauge.

Standard: 0.073 to 0.156 mm { 0.003 to 0.006 in }

Limit: 0.3 mm { 0.012 in }

Caution

- If the measured value exceeds the limit, replace the spline yoke or propeller shaft.

Legend

- Sleeve yoke

- Spline yoke

Legend

a. Play in the rotational direction

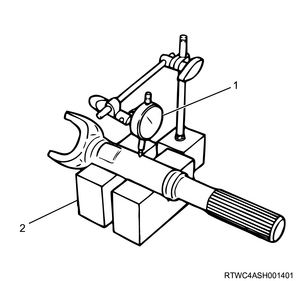

3. Tube assembly measurement

1) Check whether the propeller shaft and spline yoke slides smoothly in the axial direction.

2) Support both sides of the tube assembly with V-blocks.

3) Measure the shaft center section runout using a dial gauge.

Standard: 0.3 mm { 0.012 in }

Limit: 0.5 mm { 0.02 in }

Legend

- Dial gauge

- V-block

Caution

- If the runout exceeds the standard value, repair any minor issues using a bench press. If it greatly exceeds the standard value or exceeds the limit, replace the tube assembly.