1. Using the thread liquid gasket

1. General precautions

Make sure to use liquid gasket with the following product names or equivalent. Also, follow the handling precautions for the product.

| Type |

Product name |

Manufacturer |

Location of use (Reference) |

| Silicon type (Room-temperature vulcanized) |

ThreeBond 1207B ThreeBond 1207C ThreeBond 1215 ThreeBond 1216 ThreeBond 1281 |

ThreeBond |

Engine oil seal retainer Engine oil pan Timing gear case Cylinder head cover Fuel supply pump Water pump Rear axle etc. |

| Water soluble |

ThreeBond 1141E |

||

| Solvent based |

ThreeBond 1102 ThreeBond 1104 ThreeBond 1194 |

||

| Anaerobic |

LOCTITE 515 LOCTITE 518 LOCTITE 17430 FMD127 |

LOCTITE |

Engine oil seal retainer Water pump etc. |

Caution

- Do not use LOCTITE 515, 518, or FMD 127 as they are anaerobic and do not provide sufficient effect if there is a 0.25 mm {0.010 in} or larger gap between the contact surfaces of metals.

- For areas where liquid gasket is used, completely remove any old liquid gasket from each part and mating part using a scraper, and clean using a shop cloth to remove any adherence of oil, moisture, or foreign material whenever disassembly is performed.

- If gasket remover is used when cleaning, waiting approximately 10 minutes after application before performing the cleaning work can improve the workability. However, do not use on plastic parts or painted parts.

2. Application precautions

Caution

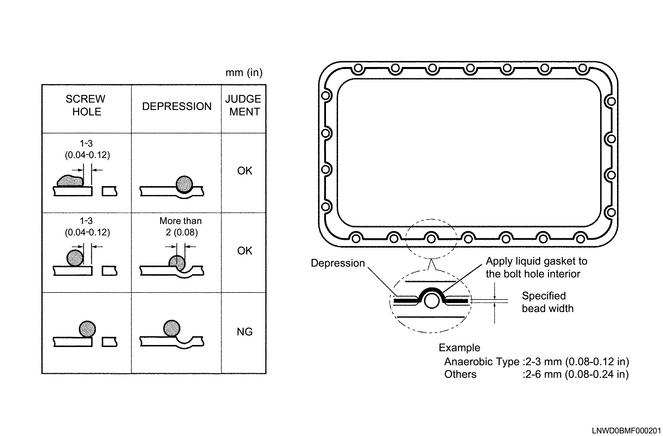

- Thoroughly apply a liquid gasket with the specified bead width to one side of the contact surface.

- Be careful not to excessively or insufficiently apply liquid gasket.

- Be sure to overlap the start and the end of the liquid gasket application.

- If the workshop manual specifies an application method, follow that method.

3. Assembly precautions after application

Caution

- Assemble within 15 minutes of applying the liquid gasket. Also, if 15 minutes or more have passed, remove the liquid gasket and reapply.

- Be careful not to misalign the mating parts, and reapply if misalignment occurs.

- If using for a section that has no positioning such as a dowel pin, use a stud of the same size as a guide.

- Wait at least 30 minutes before starting the engine after assembling each part.