1. Final drive inspection

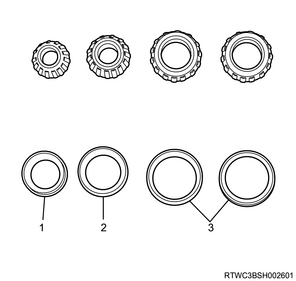

1) Inspect each bearing for the following.

- Seizing

- Spalling

- Noise

Legend

- Inner bearing

- Outer bearing

- Side bearing

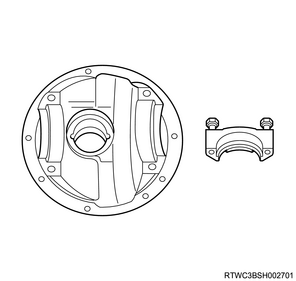

2) Inspect the differential carrier rear axle mounting section, differential carrier side bearing mounting section, as well as bearing cap for the following.

- Cracking

- Damage

- Wear

3) Inspect the pinion bearing race and pinion bearing oil seal inlay sections for the following.

- Cracking

- Damage

- Wear

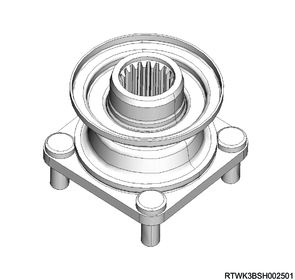

4) Inspect the flange for the following.

- Worn oil seal contact section

- Worn spline section

- Cracking of mounting section

- Damage to the mounting section

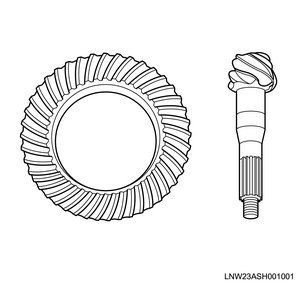

5) Inspect the gear contact surfaces on the drive and coast sides of the ring gear and drive pinion for the following.

- Chipping

- Cracking

- Spalling

- Pitting

- Improper tooth contact

6) Inspect the spline section of the drive pinion for the following.

- Cracking

- Twisting

- Damage

Caution

- Replace the ring gear and drive pinion as a set.

2. Differential cage inspection

1. Visual inspection

1) Inspect the differential cage for the following.

- Wear

- Damage

- Corrosion

- Other malfunctions

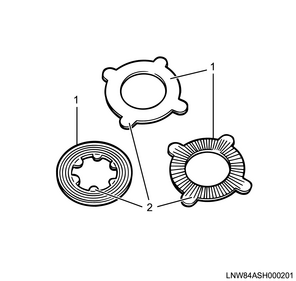

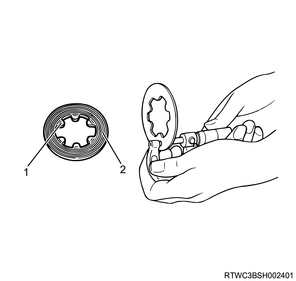

2) Inspect the friction disc, friction plate, and spring plate for the following.

- Wear

- Damage

- Abnormal noise

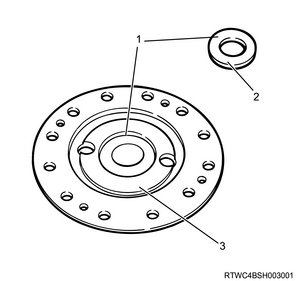

Legend

- Friction sliding surface

- Protrusion

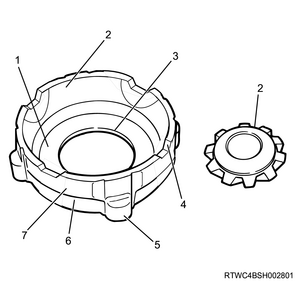

3) Inspect the following sections of the pressure ring for damage or other abnormal conditions.

- Sliding surface of the pressure ring and friction disc

- Sliding surface of the pressure ring inner surface and pinion gear

- Sliding surface of the pressure ring hole and side gear

- Sliding surface of the pressure ring and drive pinion

- Mating surface of the pressure ring and differential cage A

- Pressure ring and differential cage sliding surface

Note

- If there are dents or damage on the pressure ring and friction sliding surface, repair using an oil stone and compound.

- If there are minor burrs and dents on the pressure ring and differential cage sliding surface, repair using an oil stone.

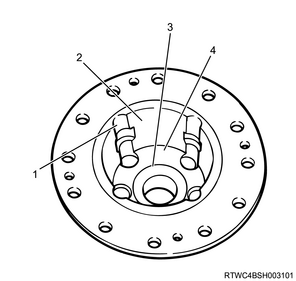

Legend

- Sliding surface of the pressure ring and side gear

- Sliding surface of the pressure ring inner surface and pinion gear

- Sliding surface of the pressure ring hole and side gear

- Sliding surface of the pressure ring and drive pinion

- Mating surface with differential cage A

- Friction disc sliding surface

- Pressure ring and differential cage sliding surface

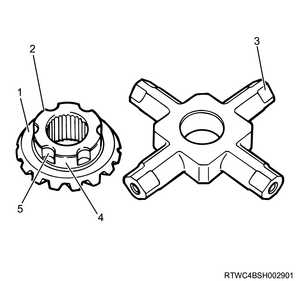

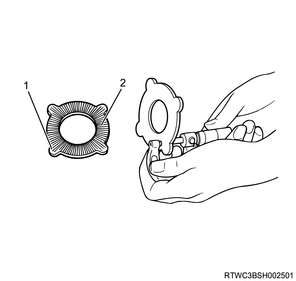

4) Inspect the following sections of the side gear thrust washer for damage or other abnormal conditions.

- Sliding surface of the pressure ring and side gear

- Sliding surface between the side gear and the thrust washer

- Sliding surface of the pressure ring and drive pinion

- Sliding surface of the pressure ring hole and side gear

- Burrs on the denting section around the side gear

Note

- Repair minor burrs and dents around the side gear using an oil stone.

Legend

- Sliding surface of the pressure ring and side gear

- Sliding surface between the side gear and the thrust washer

- Sliding surface of the pressure ring and spider

- Sliding surface of the pressure ring hole and side gear

- Burrs on the denting section around the side gear

5) Inspect the following sections of the differential cage for damage or other abnormal conditions.

- Contact surface of the differential cage and thrust washer

- Contact surface of the differential cage and spring plate

Legend

- Contact surface of differential cage A and the thrust washer

- Sliding surface of the side gear and thrust washer

- Contact surface of differential cage A and the spring plate

Legend

- Mating surface of differential cage A and differential cage A

- Sliding surface of the pressure ring and differential cage B

- Contact surface of differential cage B and the thrust washer

- Contact surface of differential cage B and the spring plate

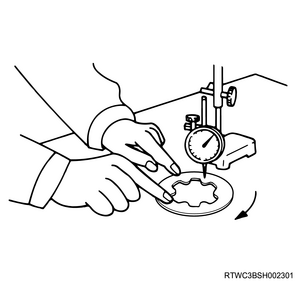

2. Friction disc and friction plate measurement

1) Measure the deformation of the friction disc and friction plate using a dial gauge.

Limit: 0.08 mm { 0.003 in }

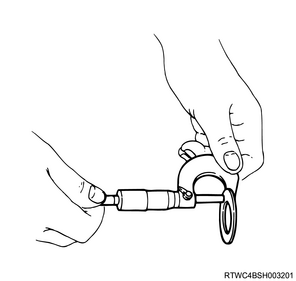

2) Measure the wear of the friction disc and friction plate using a micrometer.

Limit: 0.1 mm { 0.004 in }

Legend

- Protrusion

- Friction sliding surface

Legend

- Protrusion

- Friction sliding surface

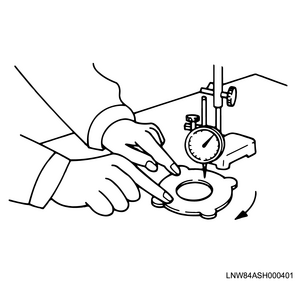

3. Side gear thrust washer measurement

1) Measure wear of the side gear thrust washer using a micrometer.

Limit: 1.3 mm { 0.05 in }