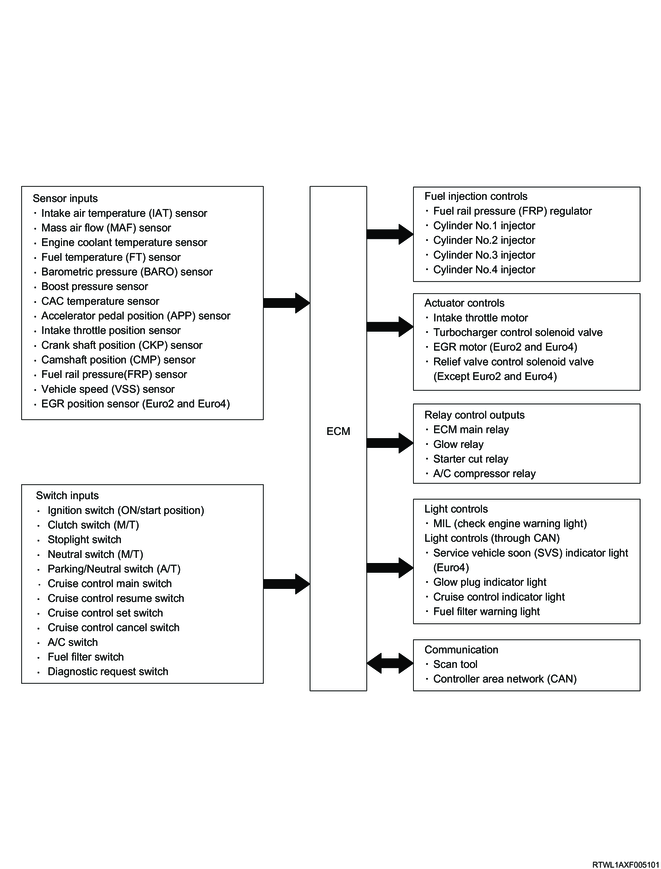

1. Engine control system overview

The engine control system is an electronic control system that controls the engine in order to constantly provide an optimal combustion state according to the driving conditions. The ECM primarily uses the information from each sensor to control the following items.

- Electronically controlled fuel injection system

- EGR

- Turbocharger control

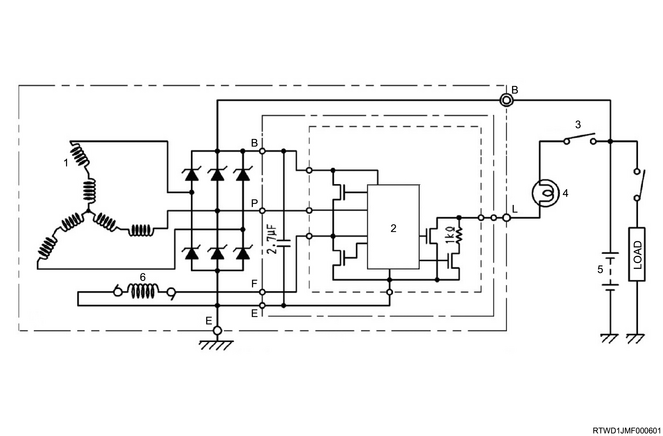

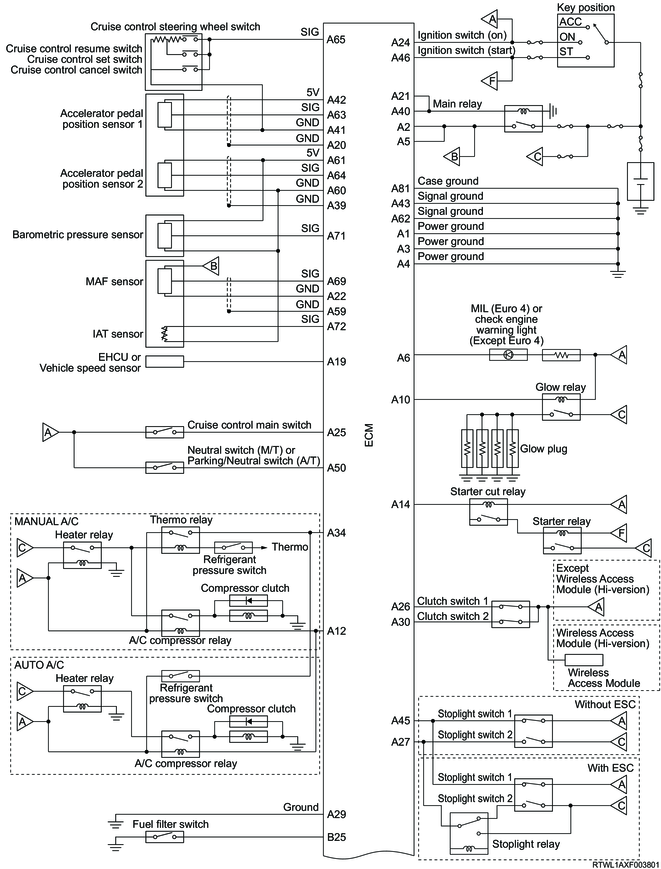

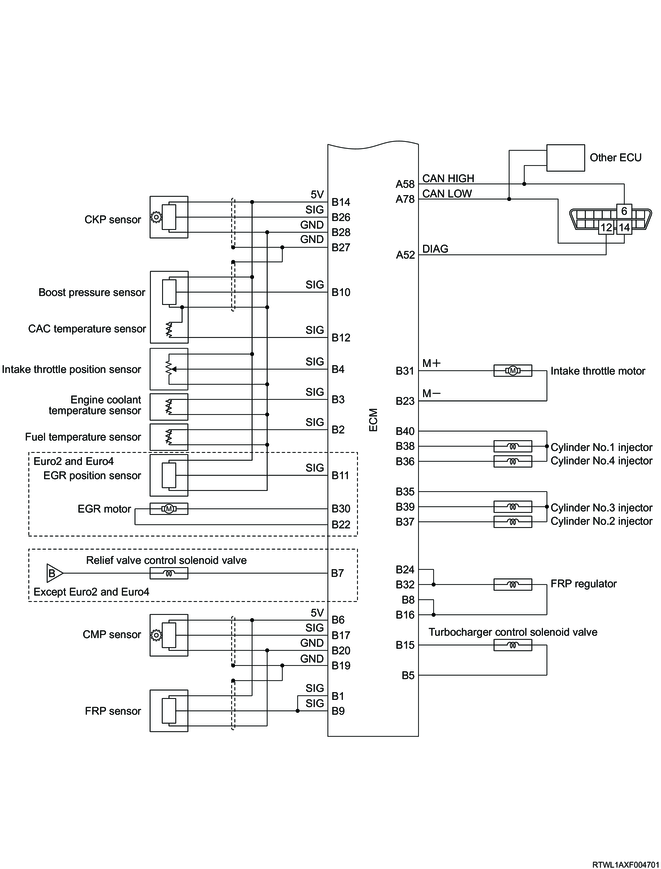

ECM input/output diagram

Note

- The components connected to the ECM may vary depending on the vehicle specifications.

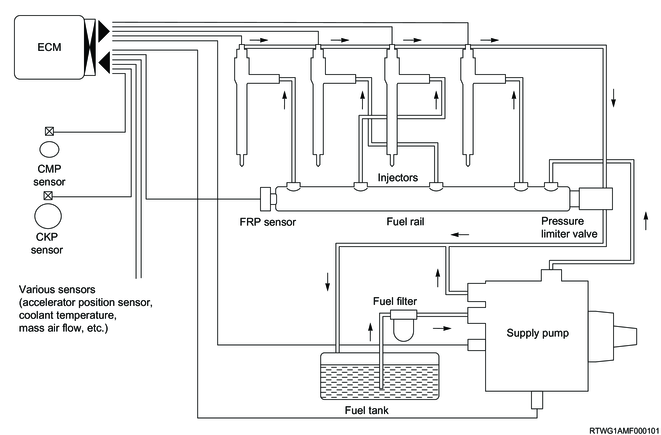

2. Fuel system description

1. System overview

The common rail (fuel rail) system contains an accumulator known as a common rail (fuel rail) to store pressurized fuel, and an injector with electronic control solenoid valve to inject the pressurized fuel into the combustion chamber. Injection control (injection pressure, injection rate, and injection timing) is controlled by the ECM, and thus the common rail (fuel rail) system can be controlled independently, free from the influence of engine speed and load. This ensures stable injection pressure at all times, particularly in the low engine speed range, and therefore significantly reduces the black smoke specific to diesel engines generated during engine starting or acceleration. As a result, the cleanliness and volume of exhaust gas are improved and higher output can be achieved.

2. Injection pressure control

High-pressure injection is enabled even in low engine speed ranges.

Control for minimizing particulate matter and NOx emissions is optimized.

3. Injection timing control

Finely tuned optimized control in accordance with running conditions is enabled.

4. Injection rate control

Pre-injection control for injecting a small amount of fuel before the main injection

The primary components of the common rail (fuel rail) system are the fuel supply pump, fuel rail, injector, and ECM.

5. Fuel injection quantity control

This control determines the fuel injection quantity by using the ECM to calculate the basic injection quantity, engine coolant temperature, fuel temperature, intake air temperature, and some switch input information according to the engine operating conditions. When the accelerator pedal is depressed to a predetermined engine speed, engine load increases and more fuel is required. By controlling the micronized fuel in combination with high-pressure injection, exhaust gases can be refined and fuel consumption reduced. Compared with conventional mechanical controllers, an electronic control system allows more freedom in the fuel injection quantity control for more precise accelerator response.

6. Start-up injection quantity control

When the engine is started, the proper fuel injection quantity is controlled based on the engine speed and engine coolant temperature. At low temperatures, the fuel injection quantity increases. When the engine is started completely, the boosted quantity mode at startup is canceled and the normal running mode is restored.

7. Idle speed control

Control is performed in order to achieve a stable idle speed at all times regardless of changes to the engine over time or variations in engine condition. The ECM sets the target idle speed and controls the fuel injection quantity according to the engine conditions so that the actual engine speed remains close to the target idle speed, ensuring a stable idle speed.

8. Idling vibration control

Engine vibration caused by torque variations between cylinders resulting from variability in injector performance or fuel injection quantities at different cylinders is reduced. The ECM corrects the injection quantity between cylinders based on the revolution signals from the CKP sensor. The normal range of correction quantity between cylinders is within -5 to 5 mm3.

9. Correction value learning for small fuel injection quantity

The ECM corrects the difference between the desired injection quantity and the actual injection quantity due to time-related deterioration, etc., in order to improve accuracy during small fuel injection quantity. This correction allows drivability improvement and engine noise (combustion noise) reduction effect. During the correction value learning for small fuel injection quantity, the ECM performs injection of a small amount of fuel during deceleration (when no fuel is injected) and determines the correction amount by detecting the change of engine speed generated from the fuel injection.

Note

- If the injector is replaced, it is necessary to reset the learned values using the scan tool.

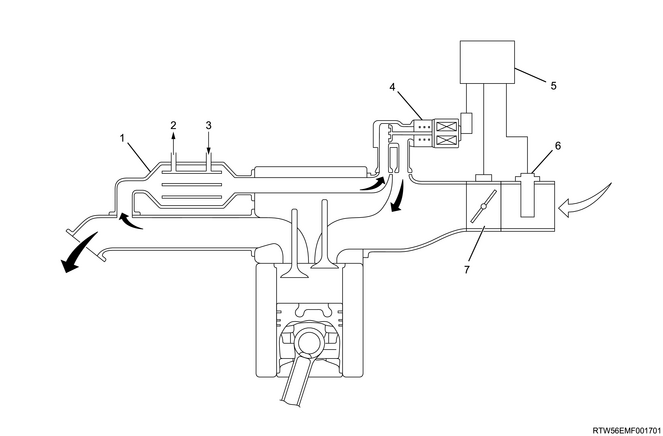

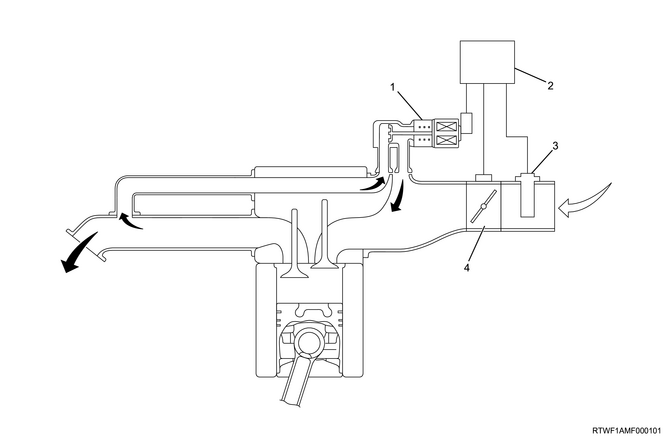

3. EGR system

1. EGR system (Euro2 and Euro4)

The EGR system recirculates a part of the exhaust gas back into the inlet cover, which results in reduced nitrogen oxide (NOx) emissions. Higher operability and emission reduction are both realized by controlling the EGR system. A control current from the ECM operates a motor to control the lift amount of the EGR valve. In addition, the EGR position sensor is used for detection of the actual valve lift amount and for precise control of the EGR amount. The EGR is activated when the specified conditions of engine speed, engine coolant temperature, intake air temperature, and barometric pressure are met. Then, the valve opening position is calculated based on engine speed and the desired fuel injection quantity. The motor drive duty is determined based on this valve opening position, and the valve is driven according to the motor drive duty.

Euro4

Legend

- EGR cooler

- Engine coolant outlet

- Engine coolant inlet

- EGR valve

- ECM

- MAF and IAT sensor

- Intake throttle valve

Euro2

Legend

- EGR valve

- ECM

- MAF and IAT sensor

- Intake throttle valve

4. Turbocharger description

1. Turbocharger

The turbocharger is used to increase the amount of air that enters the engine cylinders. This allows a proportional increase of fuel to be injected into the cylinders, resulting in higher output. Heat energy and pressure in the exhaust gas are utilized to rotate the turbine wheel. Exhaust gas directly enters the turbine housing and rotates the turbine wheel. Because the compressor wheel is attached directly to the turbine shaft, the compressor wheel rotates at the same speed as the turbine wheel. Air from the air cleaner is drawn into the compressor housing and compressor wheel. The air is compressed, passes through the intercooler and inlet cover, then enters the cylinders.

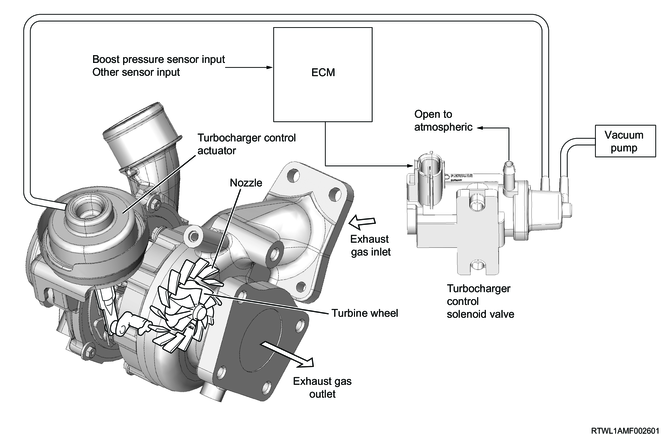

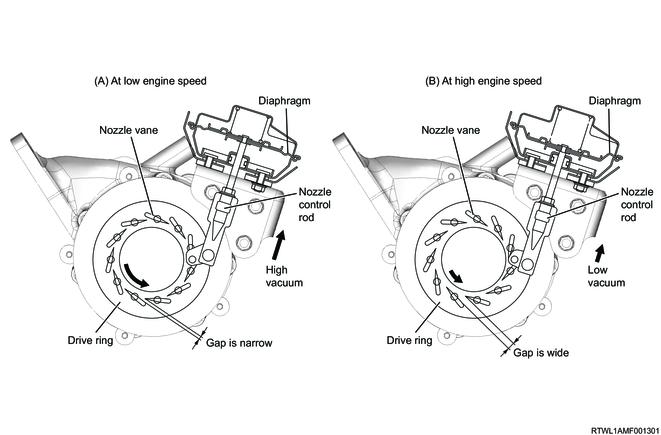

2. Turbocharger control

The amount of compressed air sent from the compressor to the engine is indirectly controlled by the turbocharger control actuator. The turbocharger control actuator is controlled by the ECM. The ECM utilizes the turbocharger control actuator and boost pressure sensor to control the turbocharger nozzles. When the engine speed is low, the turbocharger nozzles are closed. When the engine speed increases, the turbocharger nozzles open. The ECM changes the boost pressure according to engine load. The turbocharger control solenoid valve is controlled by the ECM via pulse width modulation (PWM). Engine performance is improved by compressed air passing through the intercooler. Intake air passes through the air cleaner and is drawn into the turbocharger compressor housing. Pressurized air from the turbocharger then flows into the intercooler located at the front of the radiator and into the inlet cover. When the turbocharger increases the air pressure, it raises the temperature at the same time. The intercooler is a heat exchange device that uses ambient airflow to dissipate heat from the intake air. When the intake air temperature decreases, a larger amount of air particles can be filled in the same space, which improves engine efficiency and engine output.

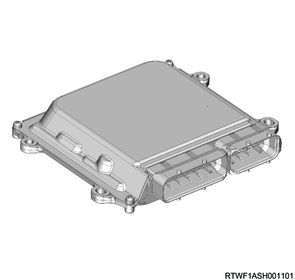

5. ECM

1. ECM

The ECM constantly monitors the information sent from various sensors and controls each system of the powertrain. The ECM performs the diagnostic functions of the system, detects operational problems with the system, warns the driver via the MIL, and stores DTCs. The DTC identifies the areas where problems have occurred to assist the repair operation performed by the technician.

2. ECM voltage description

The ECM applies the specified voltage to various switches and sensors. The ECM is able to apply voltage in such a way because the ECM resistance is very high, and the voltage that is actually applied to the circuit is low. Therefore, the test lamp may not illuminate even if it is connected to the circuit. The voltmeter that is normally used at maintenance factories may not display a correct reading because its input impedance is too low. An accurate voltage reading can be obtained by using a DMM with an input impedance of 10 MΩ. The input/output devices in the ECM include analog-to-digital converters, signal buffers, counters, and special drivers. The ECM uses electronic switches to control most components.

6. Engine controls components

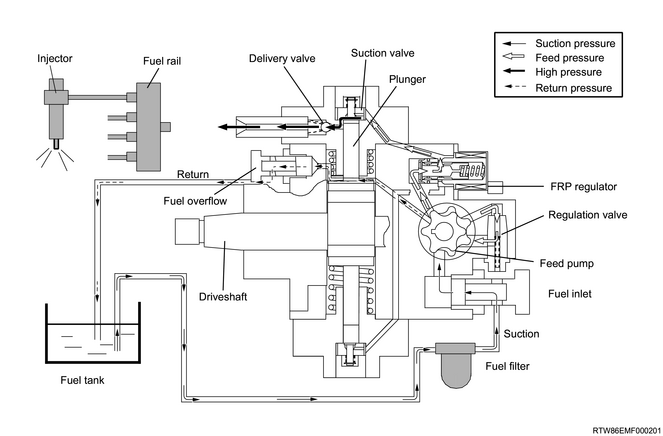

1. Fuel supply pump

The fuel supply pump is the main part of the common rail (fuel rail) type electronic fuel injection system. The fuel supply pump is installed in the same location as a conventional injection type pump, and rotates at a 1-to-1 ratio of fuel supply pump to crankshaft speed. The FRP regulator and fuel temperature sensor are components of the fuel supply pump. By way of the internal supply pump (trochoid type), fuel is sent from the fuel tank to the fuel supply pump. This supply pump feeds into 2 plunger chambers that are located inside the fuel supply pump. The fuel entering this chamber is controlled by the FRP regulator. The FRP regulator is controlled solely by the current supplied from the ECM. When no current is flowing to the solenoid, the fuel flow amount will be at maximum. Conversely, when the flow of current to the solenoid reaches its maximum, the flow of fuel will cease completely. As long as the engine is running, these 2 plungers will create a high-pressure condition within the fuel rail. The fuel supply amount and pressure to the fuel rail is controlled by the FRP regulator according to signals from the ECM. This allows for operation to be optimized, as well as for improved fuel efficiency and decreased emissions of nitrogen oxide (NOx).

2. Fuel rail (common rail)

Along with the employment of a common rail (fuel rail) type electronic control fuel injection system, a fuel rail is provided between the fuel supply pump and the injectors in order to store highly pressurized fuel. The FRP sensor and pressure limiter are installed to the fuel rail. The FRP sensor detects the fuel pressure inside the fuel rail, and sends signals to the ECM. Based on these signals, the ECM controls the fuel pressure inside the fuel rail using the FRP regulator of the fuel supply pump. When the fuel pressure inside the fuel rail is excessively high, the pressure limiter mechanically opens the valve to release pressure.

Legend

- FRP sensor

- Pressure limiter

3. Fuel rail pressure (FRP) sensor

The fuel rail pressure (FRP) sensor is installed to the fuel rail. The sensor detects the fuel pressure in the fuel rail and converts the pressure to a voltage signal. The ECM monitors the FRP sensor signal voltage. The signal voltage increases as the fuel rail pressure rises, while it decreases as the pressure declines. The ECM calculates the actual fuel rail pressure from the voltage signal and uses the result in the fuel injection control and other control tasks.

4. Pressure limiter

The pressure limiter relieves pressure by opening the valve if abnormally high pressure is generated. The valve opens when the pressure in the fuel rail reaches approximately 220 MPa {32,000 psi}, and closes when the pressure falls to approximately 50 MPa {7,250 psi}. Fuel that is relieved from the pressure limiter returns to the fuel tank.

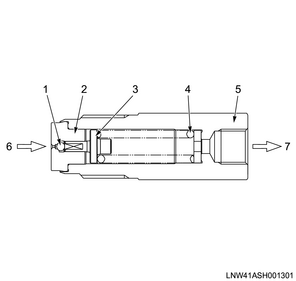

Legend

- Valve

- Valve body

- Valve guide

- Spring

- Housing

- Fuel inlet

- Fuel outlet

5. FRP regulator

The FRP regulator is installed to the fuel supply pump. The ECM controls the duty ratio of the FRP regulator (amount of time the FRP regulator is energized), and adjusts the amount of fuel supplied to the high-pressure plunger. Because only the amount of fuel necessary to achieve the desired rail pressure is sent, the drive load of the fuel supply pump decreases. When current flows to the FRP regulator, variable electromotive force is created in accordance with the duty ratio, changing the opening of the fuel passage, and thus regulating the fuel quantity. When the FRP regulator is OFF, the return spring force completely opens the fuel passage, allowing for fuel to flow to the plunger (maximum intake amount and maximum discharge amount). When the FRP regulator is ON, the solenoid inside the FRP regulator is driven to close the fuel passage (normally open). By the turning ON and OFF of the FRP regulator, fuel is supplied in accordance with the operating duty ratio and is discharged by the plunger.

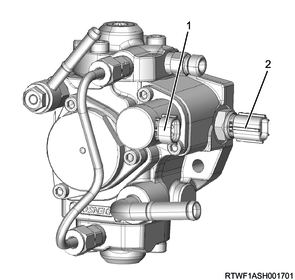

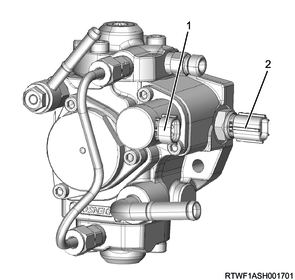

Legend

- FRP regulator

- Fuel temperature sensor

6. Fuel temperature sensor

The fuel temperature sensor is installed to the fuel supply pump. The fuel temperature sensor is a variable resistor that measures the temperature of the fuel entering the fuel supply pump. When the fuel temperature is low, the fuel temperature sensor resistance is high, and the higher the fuel temperature becomes, the lower the resistance of the sensor. The ECM detects a high voltage when the sensor resistance is high, and a low voltage when the sensor resistance is low.

Legend

- FRP regulator

- Fuel temperature sensor

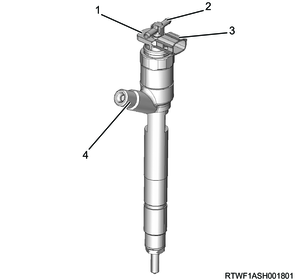

7. Injector

Compared with conventional injection nozzles, injectors electronically controlled by the ECM have command pistons, solenoid valves, etc., added. An ID code indicating various injector characteristics is laser marked on the connector housing. This system uses injector flow rate information (ID code) to optimize the injection quantity control. When an injector is newly installed in the vehicle, it is necessary to input the ID code in the ECM. The QR code or ID code on the injector is used to improve injection quantity precision. The use of codes enables injection quantity dispersion control throughout all pressure ranges, contributing to improvements in combustion efficiency and reductions in exhaust gases.

Legend

- 2D barcode

- Fuel leak-off pipe

- Injector ID Code

- Fuel inlet port

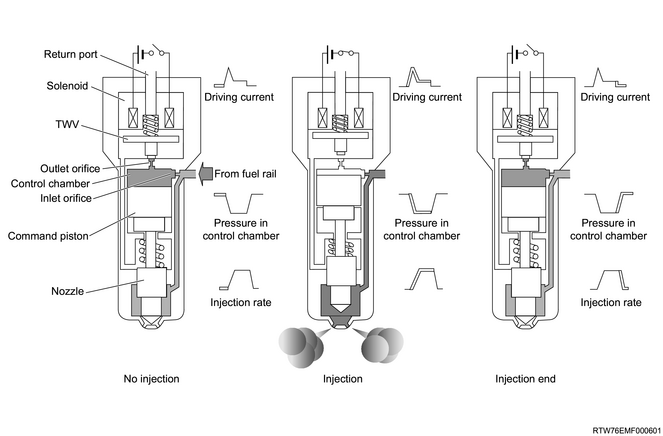

8. Injector operation

1) Non-injection state

The TWV closes the outlet orifice using spring force when no current is supplied to the solenoid from the ECM. At this time, the fuel pressure applied to the nozzle leading end is equivalent to the fuel pressure applied through the inlet orifice to the control chamber. As for the pressure balance in this state, the sum of pressure on the command piston upper surface and the nozzle spring force is greater than the pressure applied to the nozzle leading end, and as a result the nozzle is pressed down and the injection hole is closed.

2) Injection start

When the ECM supplies current to the solenoid, the TWV is pulled upwards, opening the outlet orifice and causing fuel to flow to the return port. As a result, the nozzle is pressed up along with the command piston by the pressure applied to the nozzle leading end, and the nozzle injection hole opens to inject the fuel.

3) Injection end

When the ECM finishes supplying current to the solenoid, the TWV comes down and the outlet opening is closed. As a result, the fuel stops flowing from the control chamber into the return port, and the fuel pressure within the control chamber sharply rises. Then, the nozzle is pressed down by the command piston and the nozzle injection hole is closed to stop fuel injection.

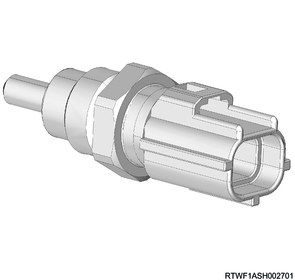

9. Engine coolant temperature sensor

The engine coolant temperature sensor is installed near the thermostat housing. The engine coolant temperature sensor is a variable resistor and measures the temperature of the engine coolant. When the engine coolant temperature is low, the engine coolant temperature sensor resistance is high, and the higher the engine coolant temperature becomes, the lower the resistance of the sensor. The ECM detects a high voltage when the sensor resistance is high, and a low voltage when the sensor resistance is low.

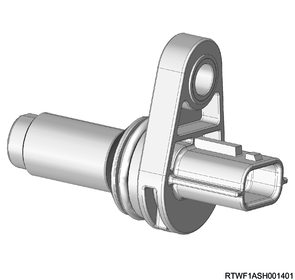

10. CMP sensor

The CMP sensor is installed to the left side of the rear of the cylinder head. The sensor rotor is fixed on the inlet camshaft gear. The sensor rotor has 4 projections evenly spaced 90° apart and 1 reference projection. The CMP sensor detects 5 projections in total per 1 engine cycle. The CMP sensor is a magnetic resistance element type sensor, and generates a square wave signal pulse.

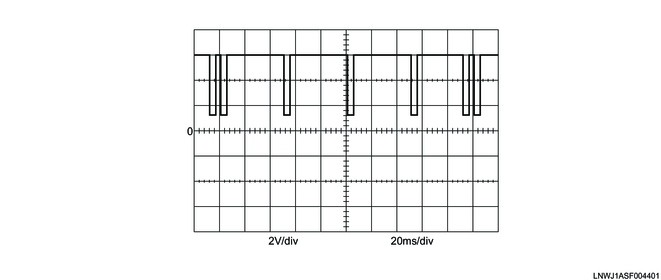

CMP sensor signal waveform (When idling)

11. CKP sensor

The CKP sensor is installed on the top of the flywheel housing. There are 56 notches spaced 6° apart and a 30° opening on the outer circumference of the flywheel. The CKP sensor can detect top dead center of cylinder No. 1 through this opening. The CKP sensor is a magnetic resistance element type sensor, and generates a square wave signal pulse. The ECM monitors the signal pulses of the CKP sensor and the CMP sensor to make sure they correlate with each other.

CKP sensor signal waveform (When idling)

12. Accelerator pedal position sensor

The accelerator pedal position sensor is installed as a set with the accelerator pedal. The sensor consists of 2 sensors in 1 housing. The ECM uses the accelerator pedal position sensor to calculate the desired acceleration and deceleration. The accelerator pedal position sensor is a Hall element type sensor. Each accelerator pedal position sensor sends signals related to accelerator pedal angle changes to the ECM via the signal circuit. The signal voltage of accelerator pedal position sensors 1 and 2 is kept low at first and increases as the pedal is depressed.

Legend

- Accelerator pedal position sensor

- Accelerator pedal

13. Barometric pressure sensor

The barometric pressure sensor is installed to the air cleaner. The barometric pressure sensor changes the signal voltage according to changes in the barometric pressure. The barometric pressure sensor sends signals related to the barometric pressure changes to the ECM via the signal circuit. The ECM detects a low signal voltage at high altitudes and with low barometric pressure. The ECM detects a high signal voltage with high barometric pressure. The ECM uses this voltage signal to adjust the fuel injection quantity and injection timing, as well as make altitude corrections.

14. MAF and IAT sensor

The MAF and IAT sensor is installed to the air cleaner. The MAF and IAT sensor is one sensor comprised of a MAF sensor and IAT sensor. The MAF sensor is an air flow meter that measures the amount of air that enters the engine. The MAF sensor measures a portion of the air that passes through the duct. When the amount of air entering the engine is small, it indicates deceleration or idling speed. When the amount of air is large, it indicates acceleration or a high load state.

The IAT sensor is a variable resistor and measures the temperature of the air flowing into the engine. When the intake air temperature is low, the IAT sensor resistance is high, and the higher the intake air temperature becomes, the lower the resistance of the sensor. The ECM detects a high voltage when the sensor resistance is high, and a low voltage when the sensor resistance is low.

15. Boost pressure and CAC temperature sensor

The boost pressure and CAC temperature sensor is installed to the air duct. The boost pressure and CAC temperature sensor is one sensor comprised of a boost pressure sensor and CAC temperature sensor.

The boost pressure sensor changes the signal voltage in accordance with changes in air pressure in the air intake pipe. The boost pressure sensor transmits signals related to air pressure changes in the air intake pipe to the ECM via the signal circuit. The ECM detects a low signal voltage in low boost pressure, such as when the engine is under low load. The ECM detects a high signal voltage in high boost pressure, such as when the engine is under high load.

The CAC temperature sensor is a variable resistor that measures the temperature of the air mixed with EGR gas that flows into the engine. The CAC temperature sensor resistance is high when the intake air temperature is low, and the sensor resistance decreases as the EGR gas flow rate increases and the intake air temperature increases. The ECM detects a high voltage when the sensor resistance is high, and a low voltage when the sensor resistance is low.

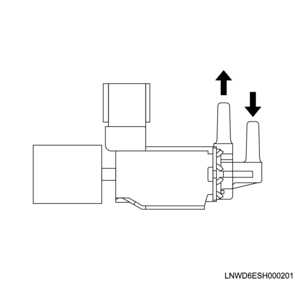

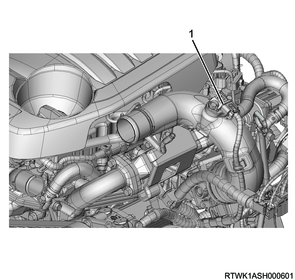

16. Turbocharger control solenoid valve

The turbocharger control solenoid valve is installed to the front of the cylinder head. The ECM controls the solenoid valve based on the boost pressure to adjust the vacuum. According to the operation of the turbocharger nozzle control diaphragm, the nozzle vane closes tighter when the vacuum is higher, and opens when there is no vacuum. The ECM adjusts the opening position of the nozzle vane to control changes in boost pressure according to the load requirements of the engine.

17. Intake throttle valve

The intake throttle valve is installed to the inlet cover. The intake throttle valve is opened and closed based on the driving condition of the engine by controlling the intake throttle motor. The motor inside the intake throttle valve is controlled according to duty ratio signals sent from the ECM. The opening position of the intake throttle valve is changed in the appropriate increments from a duty ratio of 0%. The valve closes with increases in duty ratio signals and opens when duty ratio signals decrease. The intake throttle valve opening position is detected by the position sensor, and is sent to the ECM. The position sensor sends signals related to intake throttle valve position changes to the ECM via the signal circuit. The ECM detects a low signal voltage when the valve opening is small or closed. The ECM detects a high signal voltage when the valve opening is large.

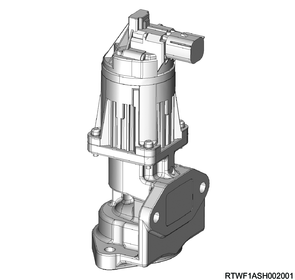

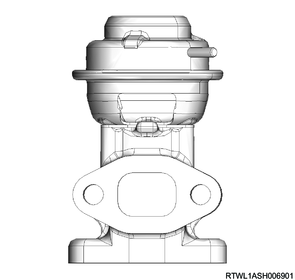

18. EGR valve (Euro2 and Euro4)

The EGR valve is installed on the inlet cover. The ECM controls the opening and closing of the EGR valve based on the driving condition of the engine by controlling the EGR motor. The motor inside the EGR valve is controlled according to the duty ratio signals sent from the ECM. The opening position of the EGR valve is changed in the appropriate increments from a duty ratio of 0%. The valve opens with increases in duty ratio signals and closes when duty ratio signals decrease. The EGR valve lift amount is detected by the position sensor and is sent to the ECM. The position sensor sends signals related to EGR valve position changes to the ECM via the signal circuit. The ECM detects a low signal voltage when the valve opening is small or closed. The ECM detects a high signal voltage when the valve opening is large.

19. Relief valve (Except Euro2 and Euro4)

The relief valve bypasses a portion of the intake air compressed by the turbocharger to the exhaust manifold. This prevents the intake pipe pressure from temporarily becoming excessively high and suppresses the surge noise of the turbocharger.

The ECM operates the relief valve via the relief valve control solenoid valve to control the intake air pressure so that it does not become excessive.

20. Relief valve control solenoid valve (Except Euro2 and Euro4)

The relief valve control solenoid valve is installed near the relief valve. The ECM operates the relief valve control solenoid valve based on input signals from each sensor. The relief valve control solenoid valve controls the vacuum pressure supplied to the relief valve.

21. MIL (Euro4)

The MIL is located in the instrument panel cluster. The symbol shown in the illustration is displayed when the MIL is ON.

When vehicle maintenance is required due to a failure related to emission, the MIL is illuminated. The following is a list of MIL operation modes.

- The MIL illuminates when the ignition switch is turned ON without starting the engine. This is a light test performed to check whether or not the MIL illuminates.

- If there is no diagnostic failure, the MIL turns OFF after the engine is started.

- If the ECM detects a failure, the MIL remains ON after the engine is started. When the ECM illuminates the MIL due to an emission-related malfunction, a DTC is stored.

22. Check engine warning light (Except Euro4)

The check engine warning light is located in the instrument panel cluster. The symbol shown in the illustration is displayed when the check engine warning light is ON.

When vehicle maintenance is required due to an emission-related malfunction, the check engine warning light is displayed. The following is a list of check engine warning light operating modes.

- The check engine warning light illuminates when the ignition switch is turned ON without starting the engine. This is a light test performed to check whether or not the check engine warning light illuminates.

- If there is no diagnostic failure, the check engine warning light turns OFF after the engine is started.

- If the ECM detects a failure, the check engine warning light remains ON after the engine is started. When the ECM illuminates the check engine warning light due to an emission-related malfunction, a DTC is stored.

23. SVS indicator light operation (Euro4)

The SVS indicator light is located in the instrument panel cluster. The symbol shown in the illustration is displayed when the SVS indicator light is ON.

When vehicle maintenance is required due to a non-emission-related malfunction, the SVS indicator light is displayed. The following summarizes the SVS indicator light operation.

- The SVS indicator light illuminates when the ignition switch is turned ON without starting the engine. This is a light test performed to check whether or not the SVS indicator light illuminates.

- If there is no diagnostic failure, the SVS indicator light turns OFF after the engine is started.

- If the ECM detects a failure, the SVS indicator light remains ON after the engine is started. When the ECM illuminates the SVS indicator light due to a non-emission-related malfunction, a DTC is stored.

7. Engine mechanical

1. Electronic engine control

The fuel injection quantity and injection timing are controlled by the ECM.

2. Cylinder block

The cylinder block made of cast iron and a highly rigid structure with appropriate rib location.

3. Piston

The pistons are aluminum alloy auto-thermatic pistons, and the combustion chambers are round re-entrant types.

4. Cylinder head

The cylinder head has 4 valves for each cylinder. Tighten the head bolts using the plastic region rotational angle tightening method. Valve clearance is automatically adjusted by the HLA.

5. Crankshaft

Do not adjust the crankshaft by polishing, because it is tufftrided. Therefore, the undersize bearing is not equipped. The crankshaft main bearing is selectively assembled according to the grades of the crankshaft journal outer diameter and the crankshaft bearing housing inner diameter.

6. Connecting rod cap bolt

Tighten the mounting bolt of the connecting rod cap using the plastic region rotational angle tightening method.

8. Fuel system

1. Common rail (fuel rail) type electronically controlled injection system

The common rail (fuel rail) type control injection system is composed of a fuel supply pump that sets and supplies the desired pressure of high-pressure fuel, a fuel rail that measures the high-pressure fuel, and an injector that injects the high-pressure fuel after it has been micronized. The ECM controls the injection timing and injection quantity under various vehicle operation conditions based on various signals.

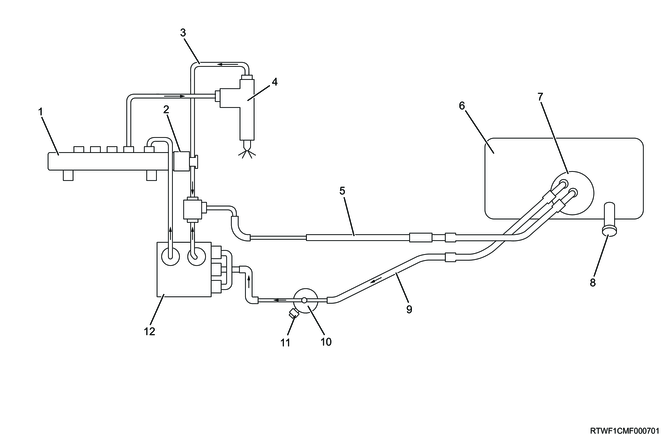

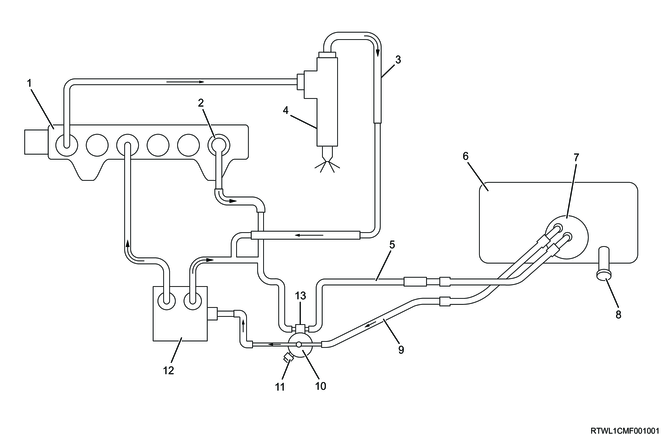

2. Fuel system diagram

Without recirculation valve

Legend

- Fuel rail

- Pressure limiter valve

- Leak-off pipe

- Injector

- Fuel return pipe

- Fuel tank

- Fuel tank unit

- Fuel filler cap

- Fuel feed pipe

- Fuel filter (With sedimenter)

- Clogging switch

- Fuel supply pump

With recirculation valve

Legend

- Fuel rail

- Pressure limiter valve

- Leak-off pipe

- Injector

- Fuel return pipe

- Fuel tank

- Fuel tank unit

- Fuel filler cap

- Fuel feed pipe

- Fuel filter (With sedimenter)

- Clogging switch

- Fuel supply pump

- Recirculation valve

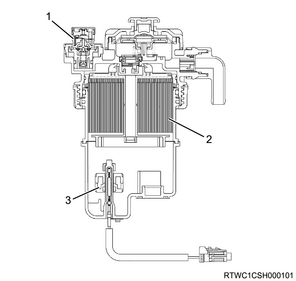

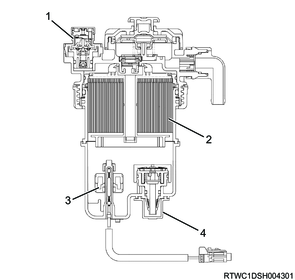

3. Fuel filter

The fuel filter has a sedimenter to remove moisture by using the difference of the relative density of diesel oil and water, and it also has an indicator that shows water accumulation.

Legend

- Clogging switch

- Fuel filter element

- Sedimenter switch

With recirculation valve

Legend

- Clogging switch

- Fuel filter element

- Sedimenter switch

- Recirculation valve

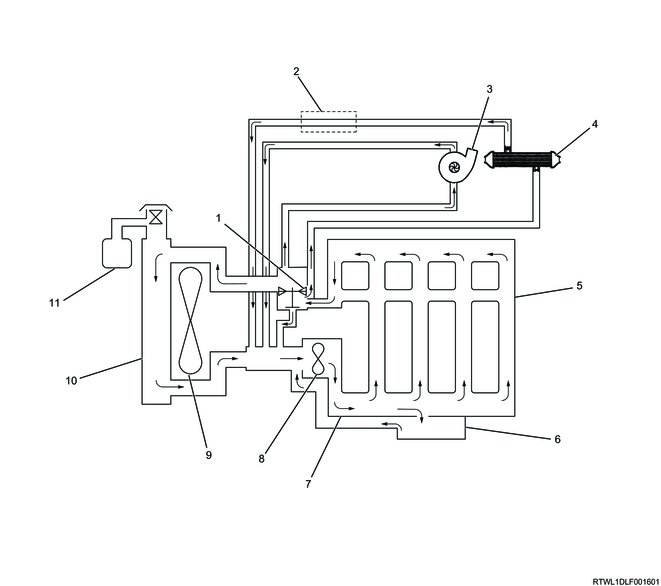

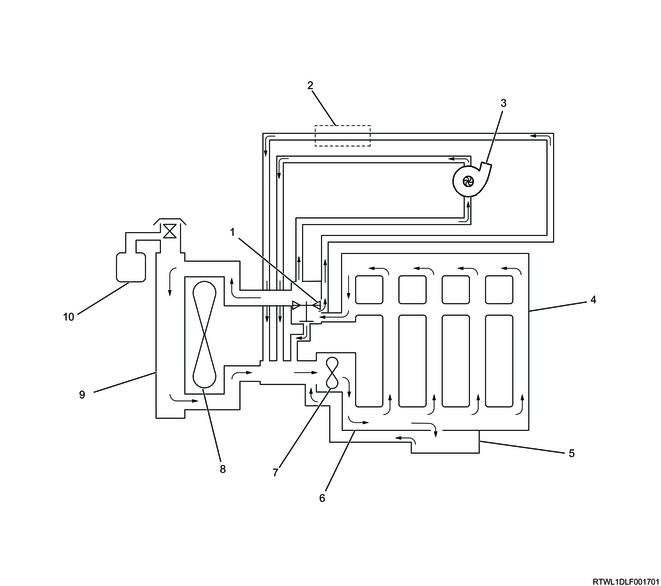

9. Cooling system

The cooling system is a force-circulation system, and its main components are the water pump, thermostat, cooling fan, and the radiator.

To quickly increase cold engine coolant temperature for smooth engine operation, the engine coolant is circulated by the water pump and the thermostat through the bypass pipe and back to the cylinder body. At this time, the engine coolant does not circulate through the radiator.

When the engine coolant temperature reaches the specified value, the thermostat begins to open to gradually increase the amount of engine coolant circulating through the radiator.

When the engine coolant temperature reaches the specified value, the thermostat is fully opened. Then all of the engine coolant circulates through the radiator to cool the engine effectively.

1. Cooling System

Euro 4 specifications

Legend

- Thermostat

- ATF cooler/warmer/heater

- Turbocharger

- EGR cooler (Euro4 specifications)

- Cylinder head

- Oil cooler

- Cylinder block

- Water pump

- Cooling fan

- Radiator

- Reserve tank

Except Euro4 specifications

Legend

- Thermostat

- ATF cooler/warmer/heater

- Turbocharger

- Cylinder head

- Oil cooler

- Cylinder block

- Water pump

- Cooling fan

- Radiator

- Reserve tank

2. Water pump

The centrifugal water pump forcibly circulates engine coolant in the cooling system.

The water pump cannot be disassembled.

3. Thermostat

The thermostat is a wax pellet type.

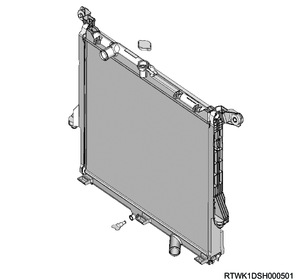

4. Radiator

The radiator is a tube type with corrugated fins. To raise the boiling point of the engine coolant, a pressurized radiator cap is attached. The radiator cap open valve pressure is 93.3 to 122.7 kPa {0.95 to 1.25 kg/cm2 / 14 to 18 psi}.

The radiator cap opens and closes using a double action mechanism.

Caution

- When removing the radiator cap, do not pull it by force, but loosen it until it cannot rotate further.

- To install the cap, turn the radiator cap until it does not turn.

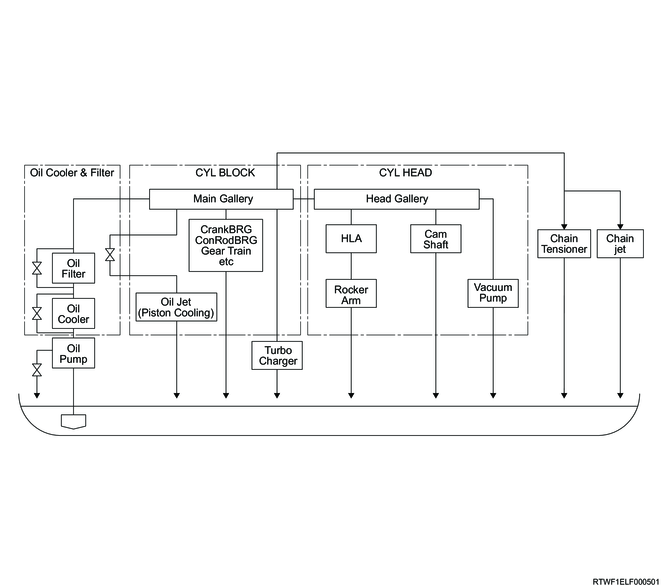

10. Lubrication system

The lubrication system uses a full-flow filter element with integrated bypass, a water-cooled oil cooler, and oil jets for cooling the pistons.

Oil is sent from the oil gallery and through the water-cooled oil cooler to lubricate each sliding section.

1. Lubricating system diagram

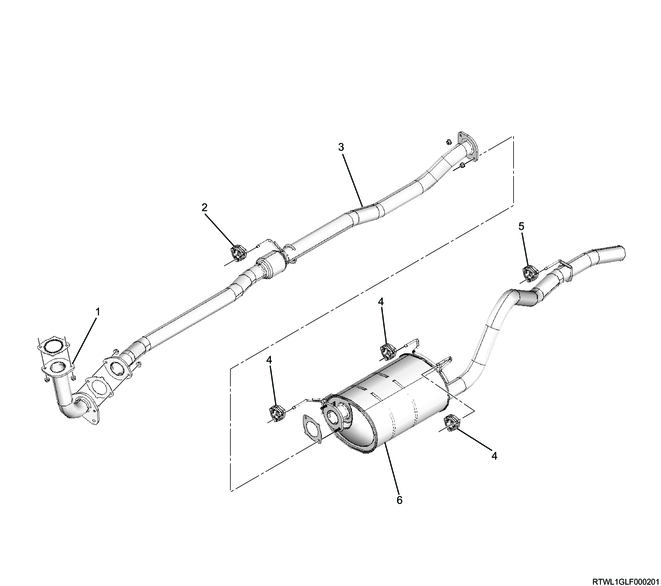

11. Exhaust system

The main components consist of the front exhaust pipe and exhaust silencer.

Legend

- Front exhaust pipe A

- Front hanger rubber

- Front exhaust pipe B

- Silencer hanger rubber

- Rear hanger rubber

- Exhaust silencer

12. Emission control devices

1. EGR system

The EGR system recirculates a part of the exhaust gas to the inlet cover, and by mixing in inert gas with intake air, the combustion temperature is lowered and the NOx generation is suppressed.

The control method of this EGR employs an electronic control method that ensures both drivability and low emissions. This activates the direct current motor using a control current from the ECM to control the EGR valve.

Legend

- EGR cooler (Euro4 specifications)

- ECM

- EGR valve

13. Electrical system

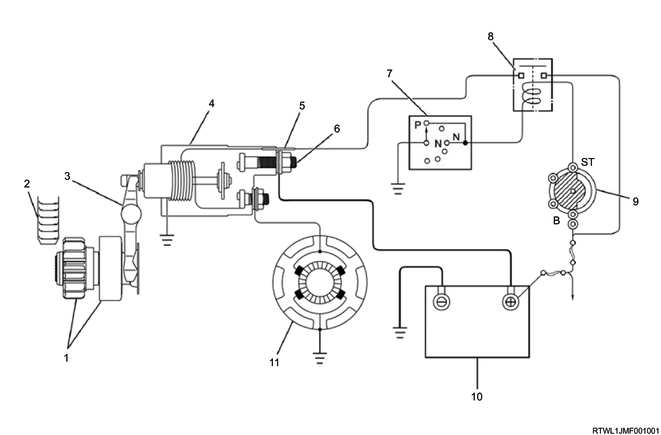

1. Starter circuit

The starting system consists of the batteries, starter, ignition switch, inhibitor switch (A/T only), starter relay, etc. Each of these main components is wired as shown in the starter circuit diagram.

Legend

- Pinion clutch

- Ring gear

- Shift lever

- Magnetic switch

- S-terminal

- B-terminal

- Inhibitor switch (For AT models only)

- Starter relay

- Ignition switch

- Battery

- Armature

Starter circuit diagram

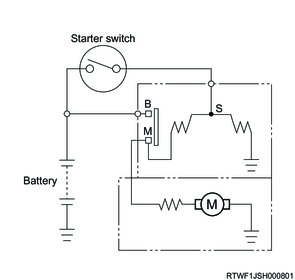

2. Starter

The starter is a magnetic shift type and is an outer gearing mesh method reduction starter.

The contact point of the magnetic switch closes and the armature rotates when the ignition switch is turned ON. At the same time, the plunger is drawn in and the pinion is pushed to the front via the shift lever to mesh with the ring gear, and when the ring gear rotates, the engine starts. After the engine starts, the plunger returns, the pinion separates from the ring gear, and the armature stops rotating when the ignition switch is turned OFF. When the engine rotation increases faster than the pinion, the pinion will turn in reverse, but because the pinion is spinning, it does not drive the armature.

Starter motor

Legend

- Nut

- Housing

- Bearing

- Snap ring

- Pinion stopper

- Dust cover

- Magnetic switch

- Nut

- Pinion and overrunning clutch

- Snap ring

- Washer

- Shift lever

- Bearing

- Shock absorber

- Starter spring

- Internal gear

- Washer

- Clutch shaft

- Washer

- Planetary gear

- Plate

- Yoke

- M-terminal lead wire

- Armature

- Brush holder

- Bearing

- Rear cover

- Screw

- Through bolt

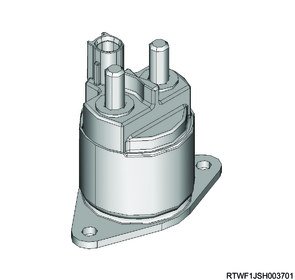

3. ICR relay

The ICR relay is installed between the battery and the starter motor, and reduces the battery voltage drop when the starter motor drives. The ICR relay turns ON and the ICR relay contact point is opened when the starter relay is turned ON. During this period, power is supplied from the battery to the starter motor via the reduction resistor. After a predetermined length of time has passed, the ICR relay turns OFF and the ICR relay contact point is closed. This allows the starter motor to drive with full battery voltage.

ICR relay

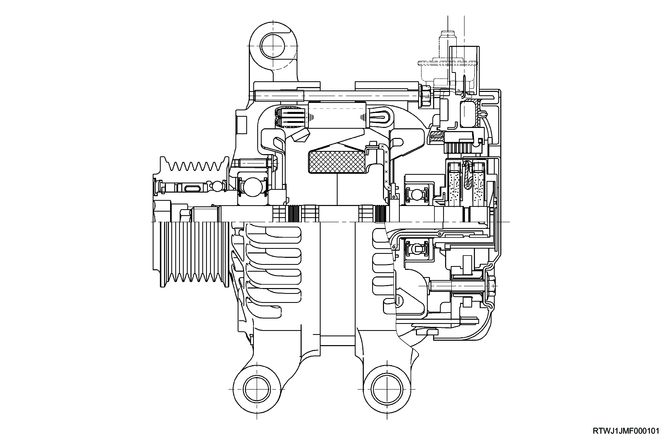

4. Generator

The charging system uses an IC integral regulator charging method. The main components are connected as shown in the diagram. The regulator is an integrated solid-state type regulator. It is built into the generator, and installed onto the rear end cover together with the brush holder.

Generator maintenance such as adjusting the voltage is not required. There are 6 diodes in the rectifier connected to the stator coil. They convert AC voltage into DC voltage. The direct current voltage is connected to the generator output terminal.

The generator cannot be disassembled.

Generator

Legend

- Stator coil

- IC regulator

- Key switch

- Charge light

- Battery

- Rotor coil

14. Engine controls component views

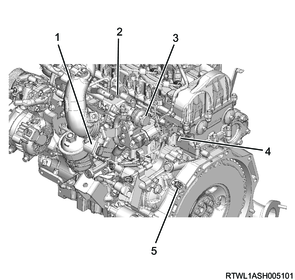

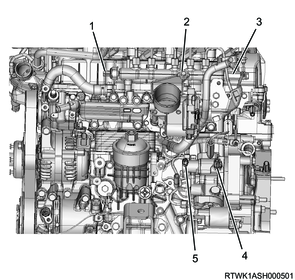

1. Engine component location diagram

Legend

- Accelerator pedal position sensor

- Accelerator pedal

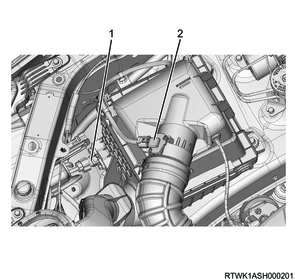

Legend

- Barometric pressure sensor

- MAF and IAT sensor

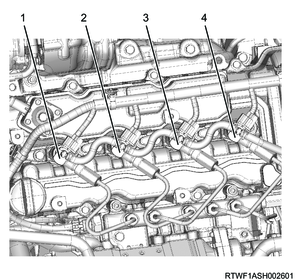

Legend

- Cylinder No. 1 injector

- Cylinder No. 2 injector

- Cylinder No. 3 injector

- Cylinder No. 4 injector

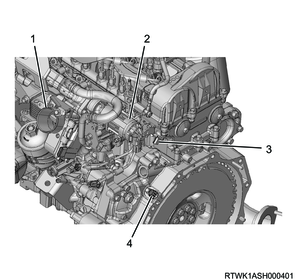

Legend

- Turbocharger control solenoid valve

- Engine coolant temperature sensor

Euro2 and Euro4

Legend

- Intake throttle valve

- EGR valve

- CMP sensor

- CKP sensor

Except Euro2 and Euro4

Legend

- Intake throttle valve

- Relief valve control solenoid valve

- Relief valve

- CMP sensor

- CKP sensor

Legend

- Boost pressure and CAC temperature sensor

Legend

- FRP sensor

- Fuel rail

- Pressure limiter

- Fuel temperature sensor

- FRP regulator

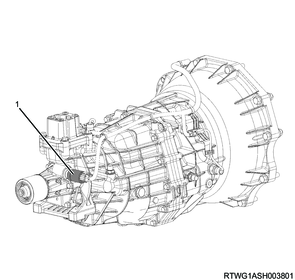

Legend

- Vehicle speed sensor (M/T)

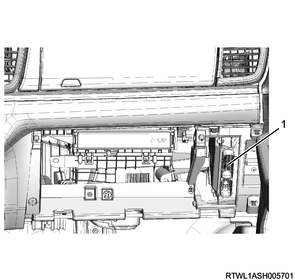

LHD models

Legend

- ECM

RHD models

Legend

- ECM

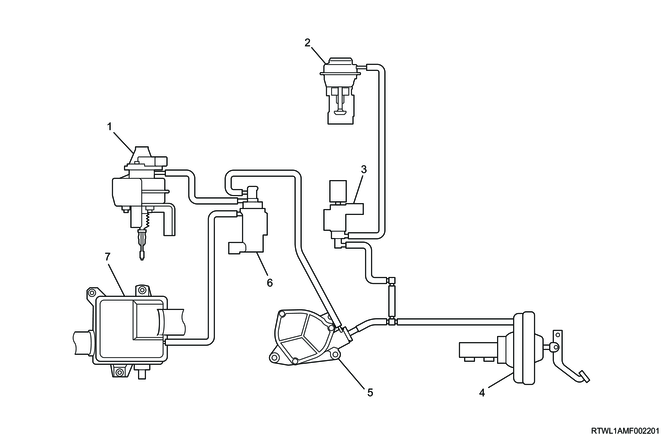

Vacuum hose routing diagram

Legend

- Turbocharger control actuator

- EGR valve

- EGR control solenoid valve

- Brake booster

- Vacuum pump

- Turbocharger control solenoid valve

- Air cleaner

15. General circuit diagram

1. General circuit diagram

1/2

2/2

Note

- The components connected to the ECM may vary depending on the vehicle specifications.

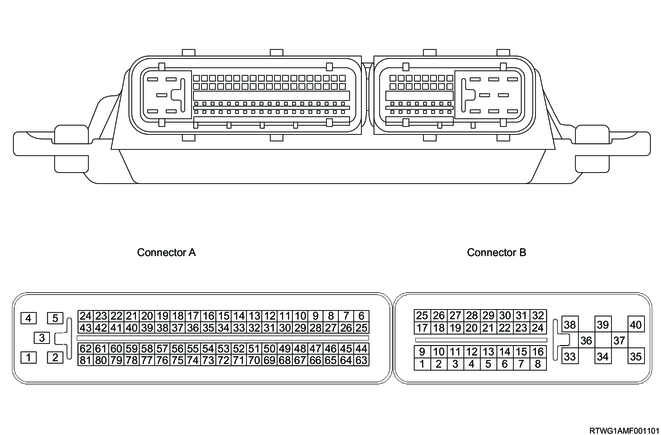

2. ECM outline

3. ECM pin layout

| PIN No. |

Pin function |

| 1 |

ECM power ground |

| 2 |

Battery voltage |

| 3 |

ECM power ground |

| 4 |

ECM power ground |

| 5 |

Battery voltage |

| 6 |

MIL control (Euro4) |

| Check engine warning light control (Except Euro4) |

|

| 7 |

- |

| 8 |

- |

| 9 |

- |

| 10 |

Glow relay control |

| 11 |

- |

| 12 |

A/C compressor relay control |

| 13 |

- |

| 14 |

Starter cut relay control |

| 15 |

- |

| 16 |

- |

| 17 |

- |

| 18 |

- |

| 19 |

Vehicle speed sensor signal |

| 20 |

Accelerator pedal position sensor 1 shield ground |

| 21 |

ECM main relay control |

| 22 |

MAF sensor low reference |

| 23 |

- |

| 24 |

Ignition voltage |

| 25 |

Cruise control main switch signal |

| 26 |

Clutch switch 1 signal |

| 27 |

Stoplight switch 2 signal |

| 28 |

- |

| 29 |

Ground |

| 30 |

Clutch switch 2 signal |

| 31 |

- |

| 32 |

- |

| 33 |

- |

| 34 |

Refrigerant pressure switch signal |

| 35 |

- |

| 36 |

- |

| 37 |

- |

| 38 |

- |

| 39 |

Accelerator pedal position sensor 2 shield ground |

| 40 |

ECM main relay control |

| 41 |

Accelerator pedal position sensor 1 and cruise control switch low reference |

| 42 |

Accelerator pedal position sensor 1, 5 volts reference |

| 43 |

ECM signal ground |

| 44 |

- |

| 45 |

Stoplight switch 1 signal |

| 46 |

Ignition switch signal |

| 47 |

- |

| 48 |

- |

| 49 |

- |

| 50 |

Neutral switch signal (M/T) |

| Parking/Neutral switch signal (A/T) |

|

| 51 |

- |

| 52 |

Diagnostic request switch |

| 53 |

- |

| 54 |

- |

| 55 |

- |

| 56 |

- |

| 57 |

- |

| 58 |

CAN high signal |

| 59 |

MAF sensor shield ground |

| 60 |

Accelerator pedal position sensor 2, barometric pressure sensor, and IAT sensor low reference |

| 61 |

Accelerator pedal position sensor 2 and barometric pressure sensor 5 volts reference |

| 62 |

ECM signal ground |

| 63 |

Accelerator pedal position sensor 1 signal |

| 64 |

Accelerator pedal position sensor 2 signal |

| 65 |

Cruise control switch signal |

| 66 |

- |

| 67 |

- |

| 68 |

- |

| 69 |

MAF sensor signal |

| 70 |

- |

| 71 |

Barometric pressure sensor signal |

| 72 |

IAT sensor signal |

| 73 |

- |

| 74 |

- |

| 75 |

- |

| 76 |

- |

| 77 |

- |

| 78 |

CAN low signal |

| 79 |

- |

| 80 |

- |

| 81 |

ECM case ground |

| PIN No. |

Pin function |

| 1 |

FRP sensor signal |

| 2 |

Fuel temperature sensor signal |

| 3 |

Engine coolant temperature sensor signal |

| 4 |

Intake throttle position sensor signal |

| 5 |

Turbocharger control solenoid valve low side |

| 6 |

CMP sensor and FRP sensor 5 volts reference |

| 7 |

Relief valve control solenoid valve |

| 8 |

FRP regulator low side |

| 9 |

FRP sensor signal |

| 10 |

Boost pressure sensor signal |

| 11 |

EGR position sensor signal |

| 12 |

CAC temperature sensor signal |

| 13 |

- |

| 14 |

CKP sensor, EGR position sensor, intake throttle position sensor, and boost pressure sensor 5 volts reference |

| 15 |

Turbocharger control solenoid high side |

| 16 |

FRP regulator low side |

| 17 |

CMP sensor signal |

| 18 |

- |

| 19 |

CMP sensor and FRP sensor shield ground |

| 20 |

CMP sensor and FRP sensor low reference |

| 21 |

- |

| 22 |

EGR motor 2 |

| 23 |

Intake throttle motor 2 |

| 24 |

FRP regulator control high side |

| 25 |

Fuel filter switch signal |

| 26 |

CKP sensor signal |

| 27 |

CKP sensor shield ground / boost pressure and CAC temperature sensor shield ground |

| 28 |

CKP sensor, EGR position sensor, intake throttle position sensor, boost pressure sensor, fuel temperature sensor, and engine coolant temperature sensor low reference |

| 29 |

- |

| 30 |

EGR motor 1 |

| 31 |

Intake throttle motor 1 |

| 32 |

FRP regulator control high side |

| 33 |

- |

| 34 |

- |

| 35 |

Common 2 (cylinder No. 2 and No. 3) injector charge voltage |

| 36 |

Cylinder No. 4 injector solenoid control |

| 37 |

Cylinder No. 2 injector solenoid control |

| 38 |

Cylinder No. 1 injector solenoid control |

| 39 |

Cylinder No. 3 injector solenoid control |

| 40 |

Common 1 (cylinder No. 1 and No. 4) injector charge voltage |

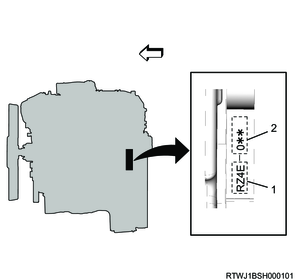

16. Engine number

Engine number stamping position

Legend

- Engine model

- Engine number