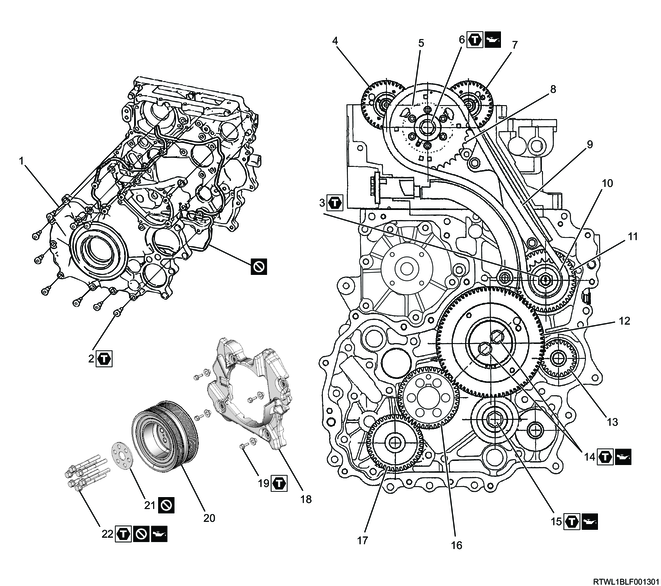

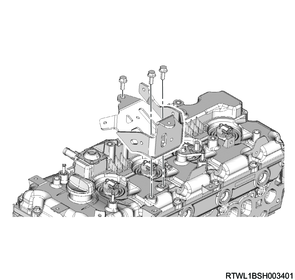

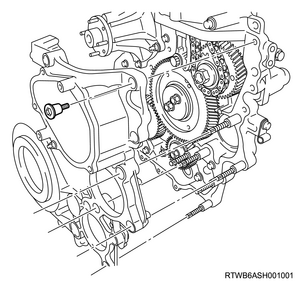

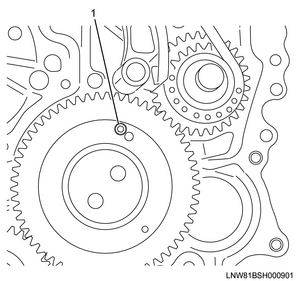

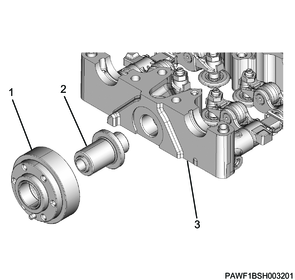

1. Component views

Idle gear

Part name

- Gear case cover

- Bolt

- Supply pump gear nut

- Exhaust camshaft gear

- Idle gear D

- Idle gear D shaft bolt

- Inlet camshaft gear

- Idle gear D sprocket

- Timing chain

- Supply pump sprocket

- Supply pump gear

- Idle gear A

- Vacuum pump gear

- Idle gear A bolt

- Flange bolt

- Crankshaft gear

- Oil pump gear

- Cover

- Bolt

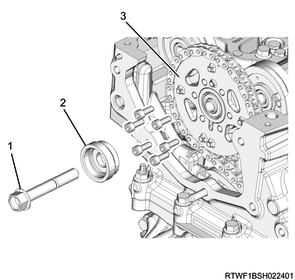

- Crankshaft pulley

- Washer

- Bolt

Tightening torque

2: 8.0 N・m { 0.8 kgf・m / 71 lb・in }

3: 130 N・m { 13.3 kgf・m / 96 lb・ft }

6: 59 N・m { 6.0 kgf・m / 44 lb・ft }

14: 32 N・m { 3.3 kgf・m / 24 lb・ft }

15: 59 N・m { 6.0 kgf・m / 44 lb・ft }

19: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

22-1: 30 N・m { 3.1 kgf・m / 22 lb・ft }

22-2: 180 °

22-3: 60 °

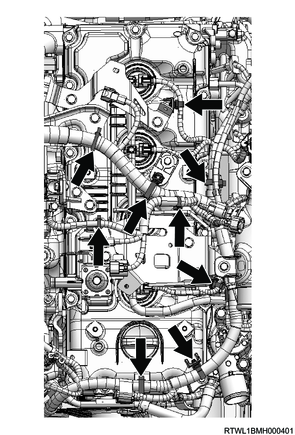

2. Crankshaft front oil seal removal

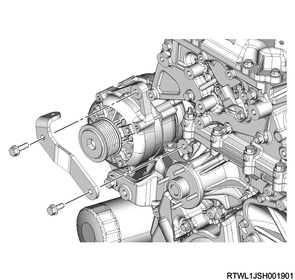

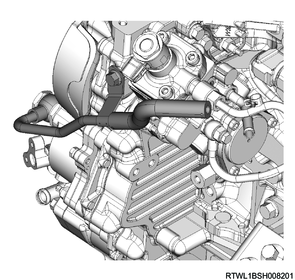

3. Generator removal

1) Disconnect the B-terminal from the generator.

2) Disconnect the connector from the generator.

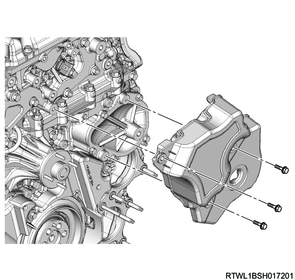

3) Remove the upper bracket from the generator and timing gear case.

4) Remove the generator from the lower bracket.

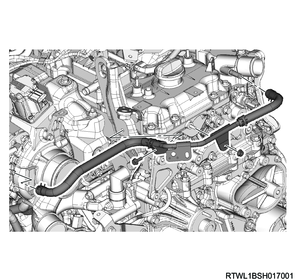

4. Water pipe removal

1) Remove the water pipe from the following parts.

- Thermostat

- Cylinder head

- Turbocharger

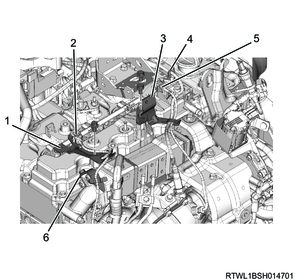

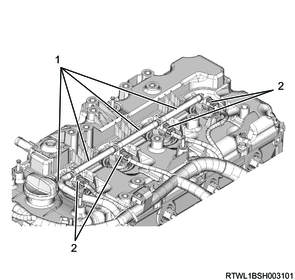

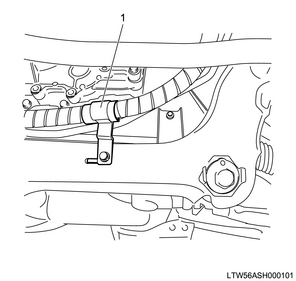

5. Exhaust differential pressure sensor removal

6. Differential pressure sensor bracket removal

1) Disconnect the following sensor harnesses from the harness bracket.

- Exhaust gas temperature sensor 1 (Front of DPD filter)

- Exhaust gas temperature sensor 2 (Front of oxidation catalyst)

- Heated oxygen sensor

2) Remove the differential pressure sensor bracket from the cylinder head cover.

3) Remove the harness bracket from the cylinder head cover.

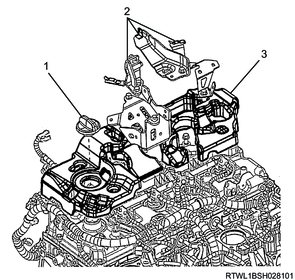

Legend

- Harness bracket

- Exhaust gas temperature sensor 1 (Front of DPD filter)

- Differential pressure sensor bracket

- Heated oxygen sensor

- Exhaust gas temperature sensor 2 (Front of oxidation catalyst)

- Harness bracket

7. Air duct bracket removal

1) Remove the air duct bracket from the cylinder head cover.

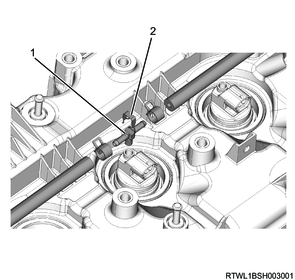

8. Fuel leak-off hose removal

1) Disconnect the connector from the injector.

2) Remove the fuel leak-off hose from the leak-off pipe.

Legend

- Fuel leak-off hose

- Injector connector

3) Remove the injector leak-off pipe from the injector.

Caution

- Do not reuse the injector leak-off pipe or clip.

Legend

- Injector leak-off pipe

- Clip

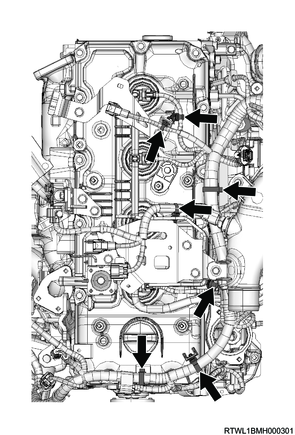

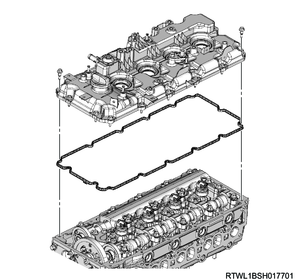

9. Cylinder head cover removal

1) Disconnect the PCV hose from the cylinder head cover.

2) Disconnect the harness clip from the cylinder head cover.

RHD

LHD

3) Remove the harness bracket from the cylinder head cover.

Note

- For models with urethane covers, remove together with the urethane cover.

- When removing the urethane cover, remove the oil filler cap before performing work.

Models with urethane covers

Legend

- Filler cap

- Harness bracket

- Urethane cover

4) Remove the cylinder head cover from the cylinder head.

Caution

- Do not reuse the gasket.

5) Remove the oil seal from the lower side of the cylinder head cover.

10. Baffle plate removal

1) Rotate the crankshaft in the forward direction (clockwise) to align the No. 1 cylinder piston to compression top dead center.

Legend

- Alignment mark of No. 1 cylinder compression top dead center

2) Remove the baffle plate from the cylinder head.

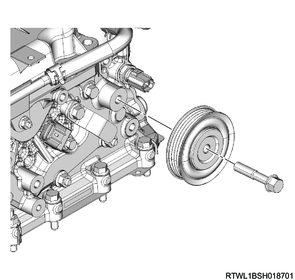

11. Timing chain lower cover removal

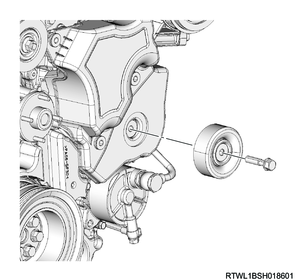

1) Remove the idle pulley from the timing chain lower cover.

2) Remove the noise cover from the timing chain lower cover.

3) Remove the timing chain lower cover from the gear case cover.

12. Tension pulley removal

1) Remove the tension pulley from the cylinder head.

13. Timing chain upper cover removal

1) Remove the idle pulley from the timing chain upper cover.

2) Disconnect the connector from the CMP sensor.

Legend

- CMP sensor

3) Remove the timing chain upper cover from the cylinder head.

Legend

- Timing chain upper cover

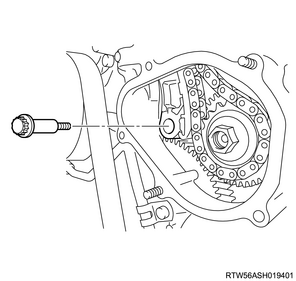

14. Timing chain removal

1) Remove the oil feed pipe from the timing chain tensioner.

Caution

- Do not reuse the gasket.

2) Remove the timing chain tensioner and gasket from the cylinder head.

Caution

- Do not reuse the gasket.

Legend

- Oil feed pipe

- Timing chain tensioner

- Gasket

3) Remove the timing chain lever pivot from the timing chain tension lever.

4) Remove the idle gear D shaft bolt and sleeve from idle gear D and sprocket.

5) Remove the timing chain and sprocket as a set from idle gear D.

Legend

- Idle gear D shaft bolt

- Sleeve

- Sprocket

6) Remove the timing chain from the supply pump sprocket by lowering the timing chain and sprocket.

7) Take the timing chain tension lever out from the cylinder head.

8) Remove the timing chain guide from the cylinder head and cylinder block.

Legend

- Timing chain guide bolt

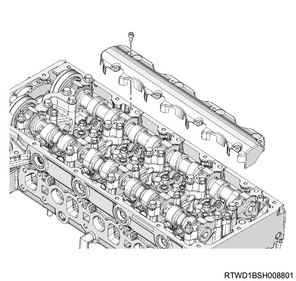

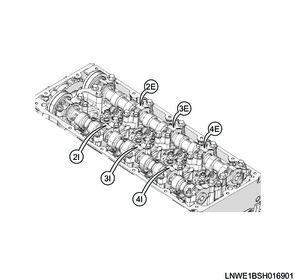

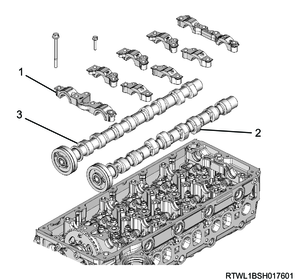

15. Camshaft removal

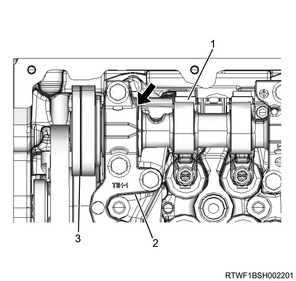

1) Measure the axial direction clearance of the camshaft gear and camshaft bracket using a feeler gauge.

Note

- If the measured value exceeds the limit, replace the camshaft.

Standard: 0.050 to 0.130 mm { 0.00197 to 0.00512 in }

Limit: 0.250 mm { 0.00984 in }

Legend

- Camshaft

- Camshaft bracket

- Camshaft gear

2) Use the M5 lock bolt to secure the camshaft gear.

3) Remove the camshaft upper bracket from the camshaft brackets.

Note

- Check that there are installation position markings on the camshaft upper brackets.

4) Remove the inlet camshaft and exhaust camshaft from the camshaft brackets.

Caution

- Take measures to prevent the inlet and exhaust sides from becoming mixed up.

Legend

- Camshaft upper bracket

- Inlet camshaft

- Exhaust camshaft

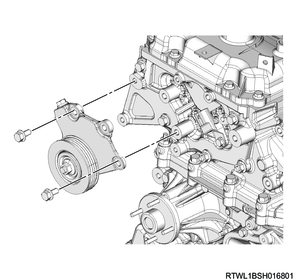

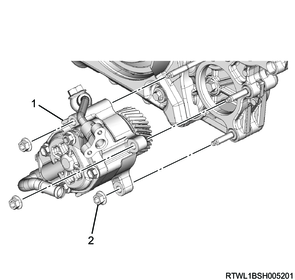

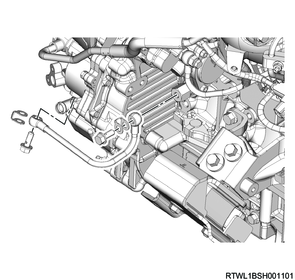

16. Power steering oil pump disconnect

1) Disconnect the power steering oil pump and power steering oil hose as a set from the timing gear case.

Legend

- Power steering oil pump

- Nut

2) Remove the power steering oil hose from the bracket.

Legend

- Bracket

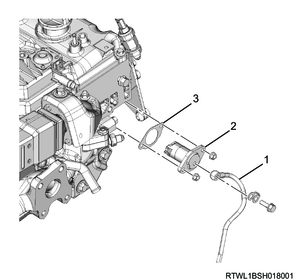

17. Vacuum pump removal

1) Remove the vacuum pipe as a set with the vacuum hose from the timing gear case and vacuum pump.

2) Remove the vacuum pump oil pipe from the vacuum pump and cylinder block.

3) Remove the vacuum pump from the gear case cover.

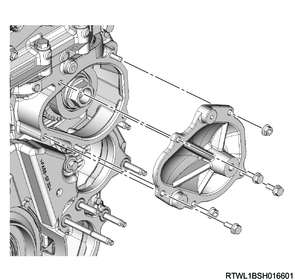

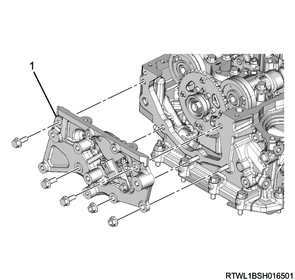

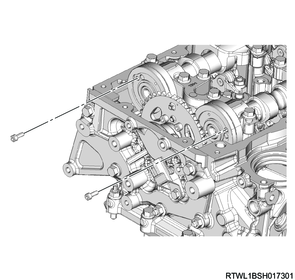

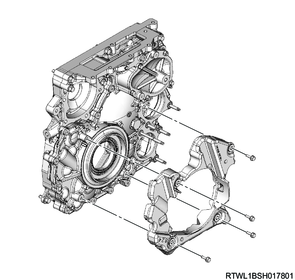

18. Gear case cover removal

1) Remove the cover from the gear case cover.

2) Remove the gear case cover from the timing gear case.

Caution

- Do not reuse the gasket.

19. Supply pump gear removal

1) Apply the dial gauge to the idle gear tooth to be measured, and gently move the gear left and right to measure the fluctuation of the dial gauge.

Note

- Replace the idle gear if the measured value exceeds the standard value.

Standard: 0.10 to 0.17 mm { 0.0039 to 0.0067 in }

Limit: 0.30 mm { 0.0118 in }

2) Measure the idle gear axial direction clearance using a feeler gauge.

Note

- Replace the idle gear or thrust collar if the measured value exceeds the limit.

| Idle gear |

Standard value |

Limit |

| A |

0.055 to 0.130 mm { 0.0022 to 0.0051 in } |

0.20 mm { 0.0079 in } |

| D |

0.090 to 0.155 mm { 0.0035 to 0.0061 in } |

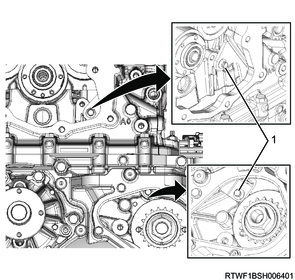

3) Turn the crankshaft in the forward direction (clockwise) to align the marks with idle gear A and the supply pump gear removal or installation position.

Note

- Referring to the diagram, align the three-dot marks.

Legend

- Supply pump installation or removal position

- TDC position

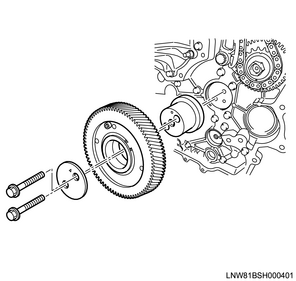

4) Install the M6 bolt for securing the sub gear to idle gear A.

Legend

- M6 bolt

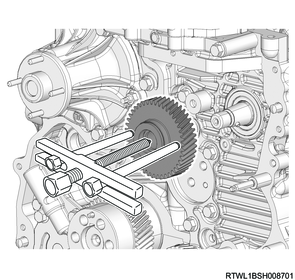

5) Remove the supply pump gear from the fuel supply pump using a gear puller.

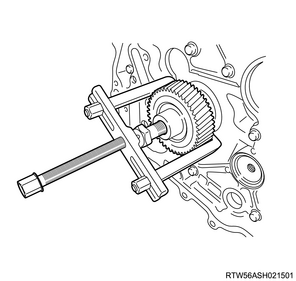

20. Idle gear removal

1) Remove the flange from idle gear A.

2) Remove idle gear A from the idle gear A shaft.

3) Remove the idle gear A shaft from the timing gear case.

4) Remove the crank gear from the crankshaft.

5) Remove idle gear D from the idle gear shaft.

6) Remove the idle gear D shaft from the camshaft brackets.

Legend

- Idle gear D

- Idle gear D shaft

- Camshaft bracket