1. Component views

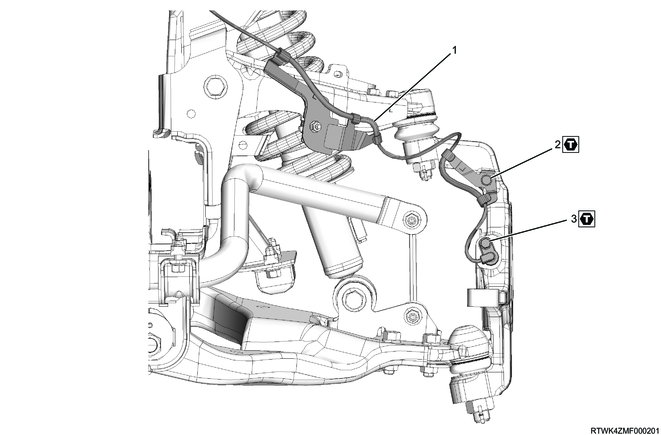

Front wheel speed sensor (2WD (Except high ride suspension specifications))

Part name

- Wheel speed sensor

- Bolt

- Bolt

Tightening torque

2: 8.2 N・m { 0.8 kgf・m / 73 lb・in }

3: 8.2 N・m { 0.8 kgf・m / 73 lb・in }

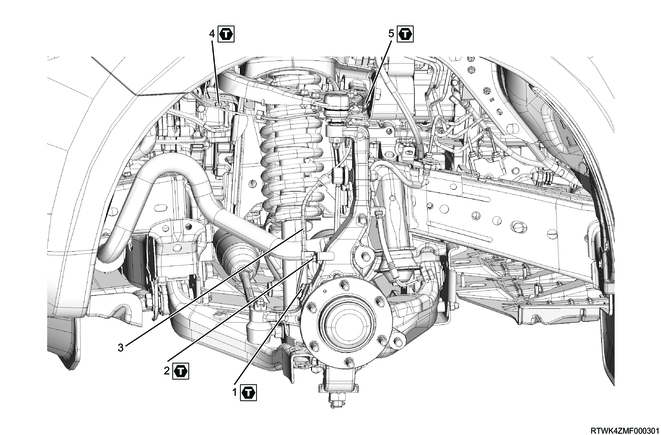

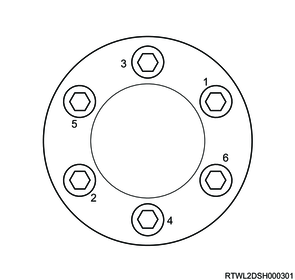

Front wheel speed sensor (2WD (High ride suspension specifications), 4WD)

Part name

- Bolt

- Bolt

- Wheel speed sensor

- Bolt

- Bolt

Tightening torque

1: 8.2 N・m { 0.8 kgf・m / 73 lb・in }

2: 8.2 N・m { 0.8 kgf・m / 73 lb・in }

4: 8.2 N・m { 0.8 kgf・m / 73 lb・in }

5: 8.2 N・m { 0.8 kgf・m / 73 lb・in }

2. Wheel speed sensor installation

1. Preparations for wheel speed sensor installation

1) Clean the following sections.

- Sensor mounting hole inside and mounting surface of the sensor bracket

- Sensor bracket mounting surface of the knuckle

Note

- Clean foreign material, such as rust and sensor fragments.

- If any rust is found, remove it with a wire brush, etc.

Caution

- If using rust penetrant when removing the wheel speed sensor, clean the part with a parts cleaner, etc.

2. Precautions for wheel speed sensor installation

Caution

- When assembling the hub, do not contact and break the wheel speed sensor body and exciter ring.

- The wheel speed sensor unit contains a magnet so that caution should be taken with metal objects.

- When removing the hub and rotor, or when removing the hub and drum, the wheel speed sensor must be removed first before starting the procedure.

- When the knuckle is removed by hammering etc., remove the wheel speed sensor before starting the work.

- When installing the sensor, use your hand to push the sensor installation flange until it is firmly attached to the installation surface, and then tighten the bolt.

- When inserting the sensor, do not pry or hammer it with a tool.

- Do not tighten the sensor body fixing bolts with an air tool, but temporarily hand tighten and then fully tighten them.

- After tightening the bolts, check that there is no clearance between the mounting flange and the mounting surface again.

- Install the sensor harness using the twist prevention line as a reference to avoid twisting.

- Take care not to pull the harness, which may result in it being cut.

- Confirm that there is no harness interference.

- Be careful not to damage the wheel speed sensor.

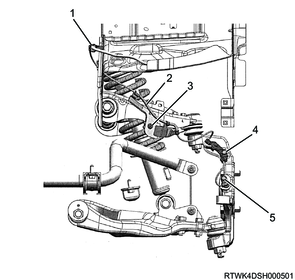

3. Installation (ABS-specification 2WD (Except high ride suspension specifications))

1) Install the wheel speed sensor to the knuckle.

Tightening torque: 8.2 N・m { 0.8 kgf・m / 73 lb・in }

2) Install the harness bracket to the upper link and knuckle.

Tightening torque: 8.2 N・m { 0.8 kgf・m / 73 lb・in } Harness bracket tightening bolt

Tightening torque: 8.2 N・m { 0.8 kgf・m / 73 lb・in } Harness bracket tightening nut

Legend

- Connector position

- Wheel speed sensor

- Harness bracket tightening nut

- Harness bracket tightening bolt

- Wheel speed sensor tightening bolt

3) Connect the harness connector to the wheel speed sensor.

4) Make sure that the harness is not twisted.

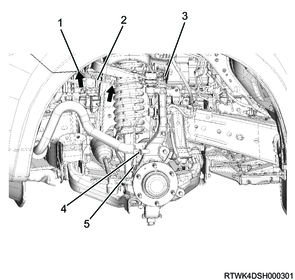

4. Installation (ABS-specification 2WD (High ride suspension specifications), ABS-specification 4WD)

1) Install the wheel speed sensor to the knuckle.

Tightening torque: 8.2 N・m { 0.8 kgf・m / 73 lb・in }

2) Install the harness bracket to the upper link and knuckle.

Tightening torque: 8.2 N・m { 0.8 kgf・m / 73 lb・in } Harness bracket tightening bolt

Tightening torque: 8.2 N・m { 0.8 kgf・m / 73 lb・in } Harness bracket tightening nut

3) Connect the harness clips to the harness as indicated by the arrows in the following diagram.

Legend

- Connector position

- Wheel speed sensor

- Harness bracket tightening nut

- Harness bracket tightening bolt

- Wheel speed sensor tightening bolt

4) Connect the harness connector to the wheel speed sensor.

5) Make sure that the harness is not twisted.

5. Inspection after vehicle restoration

1) Turn ON the ignition switch, and check whether the ABS warning light turns OFF after illuminating for approximately 3 seconds.

2) Start the engine and drive the vehicle straight forward from a stationary state. Slowly accelerate to 15 km/h {9.3 mph} and then slowly apply the brake until the vehicle stops. Check that there are no abnormal noises or problems with the braking force during this procedure.

3) Confirm whether the following symptom occurs during verification actions above.

- The ABS warning light illuminates, or does not illuminate.

- ABS operation noise or motor rotation noise is caused.

- Brake pedal kickbacks are felt.

- Desired braking force is not reached.

4) When the above symptom occurs, take the following action.

- Check the installation status of the wheel speed sensor and connection status of the connector.

- Check the DTCs, and perform inspection and take remedies for the ABS system in accordance with the diagnostic procedure for each DTC.

Caution

- Since the ABS rotates the motor for a moment right immediately after the vehicle is started, sound of rotating motor may be heard. This operation for initial confirmation task and not at fault.

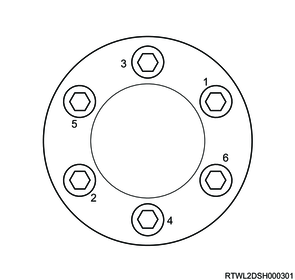

3. Disc wheel installation

1. Models with aluminum wheels

1) Temporarily tighten the disc wheel to the vehicle.

2) Lower vehicle.

3) Final tighten the wheel nut in the order shown in the diagram.

Tightening torque: 120 N⋅m {12 kgf⋅m / 87 lb⋅ft}

Caution

- After completing installation, make sure to further tighten the wheel nuts to the specified torque after the vehicle has been driven a distance exceeding the standard value.

Standard: 50 to 100 km { 31 to 62 mile }

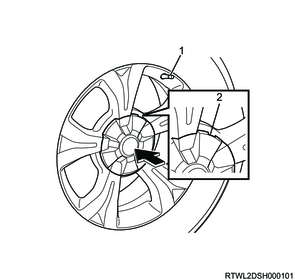

4) Install the wheel cap to the disc wheel.

Note

- For models with 18-inch aluminum wheels, align the wheel cap groove with the air valve before installing.

5) Check that the surfaces of the wheel cap and wheel are flat.

Note

- If the surfaces are not flat, the wheel cap may fall off.

Legend

- Valve

- Wheel cap groove

2. Models with steel wheels

1) Temporarily tighten the disc wheel and wheel cap to the vehicle.

2) Lower vehicle.

3) Final tighten the wheel nut in the order shown in the diagram.

Tightening torque: 120 N⋅m {12 kgf⋅m / 87 lb⋅ft}

Caution

- After completing installation, make sure to further tighten the wheel nuts to the specified torque after the vehicle has been driven a distance exceeding the standard value.

Standard: 50 to 100 km { 31 to 62 mile }

4. Preliminary and post procedures

1. Post procedures

1) Connect the battery cable to the battery negative terminal.

2) Referring to the following, perform the setting of the front door power window switch with AUTO UP/AUTO DOWN function.

Refer to "9.Body, Cab, Accessories 9T.Glass, Windows, Mirrors front door power window switch setting".

3) Close the engine hood.