1. Camshaft inspection

1. Visual inspection

1) Inspect the camshaft journal, cam section, and gear sections for the following.

- Damage

- Wear

Note

- Replace the camshaft if an abnormal condition is found.

2) Inspect the camshaft sprocket and inlet camshaft sub gear for the following.

- Damage

- Wear

Note

- Replace the camshaft sprocket if an abnormal condition is found.

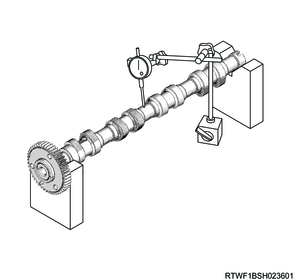

2. Camshaft runout measurement

1) Put the camshaft on the V-block.

2) Slowly turn the camshaft to measure runout of the dial gauge.

Limit: 0.05 mm { 0.0020 in }

Note

- If the measured value exceeds the limit, replace the camshaft.

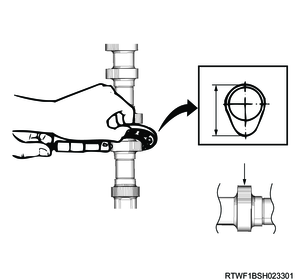

3. Cam lobe height measurement

1) Measure the height of the cam lobe using a micrometer.

Note

- If the measured value exceeds the limit, replace the camshaft.

| Inlet |

Standard value |

40.287 mm { 1.5861 in } |

| Limit |

39.287 mm { 1.5467 in } |

|

| Exhaust |

Standard value |

40.552 mm { 1.5965 in } |

| Limit |

39.552 mm { 1.5572 in } |

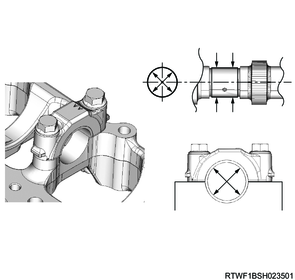

4. Camshaft journal measurement

1) Measure the diameter of the camshaft journal using a micrometer.

| Standard value |

23.943 to 23.964 mm { 0.9426 to 0.9435 in } |

| Limit |

23.843 mm { 0.9387 in } |

| Limit |

0.05 mm { 0.0020 in } Uneven wear |

Note

- If the measured value exceeds the limit, replace the camshaft.

2) Measure the inner diameter of the camshaft cap using a cylinder gauge.

3) Calculate the clearance from the camshaft cap inner diameter and journal diameter measurements.

| Standard value |

0.036 to 0.078 mm { 0.0014 to 0.0031 in } |

| Limit |

0.12 mm { 0.0047 in } |

Note

- If the measured value exceeds the limit, replace the camshaft or camshaft carrier.