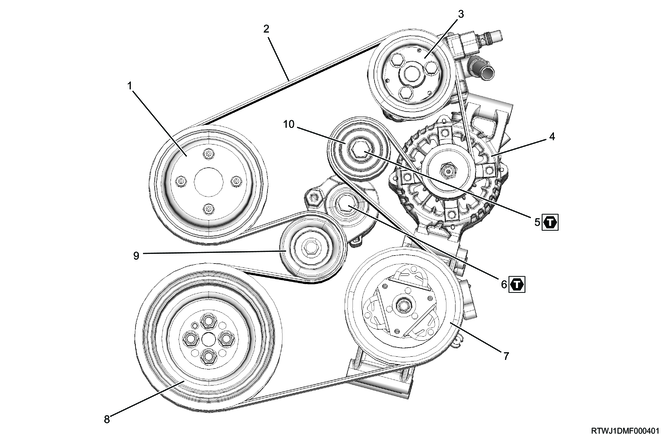

1. Component views

Cooling fan belt

Part name

- Fan pulley

- Cooling fan belt

- Power steering oil pump pulley

- Generator

- Bolt

- Bolt

- A/C compressor

- Crankshaft pulley

- Auto tensioner pulley

- Idle pulley

Tightening torque

5: 110 N・m { 11.2 kgf・m / 81 lb・ft }

6: 110 N・m { 11.2 kgf・m / 81 lb・ft }

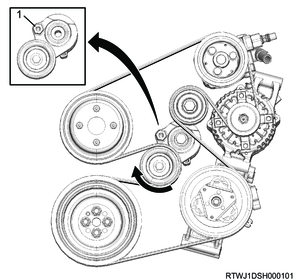

2. Cooling fan belt installation

1) Set the torque wrench on the boss section of the auto tensioner.

Caution

- Do not attach the torque wrench on the pulley bolt of the auto tensioner.

2) Install the cooling fan belt to the following parts by moving the auto tensioner pulley in the direction shown in the diagram.

- Water pump pulley

- Generator

- Auto tensioner pulley

- Idle pulley

- A/C compressor

- Crankshaft pulley

- Power steering oil pump pulley

Legend

- Boss section

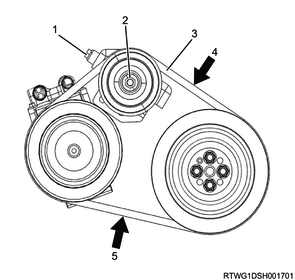

3. Freezer compressor drive belt installation

1. Freezer specifications

1) Install the freezer compressor drive belt to the following parts.

- Freezer compressor pulley

- Crankshaft pulley

- Tension pulley

4. Preliminary and post procedures

1. Post procedures

1) Close the engine hood.

5. Freezer compressor drive belt adjustment

1. Freezer specifications

When installing a new belt, initial stretching of the belt occurs.

In addition, when reusing the belt, the belt needs to be fitted to the pulley groove.

After fitting the freezer compressor drive belt, adjust the tension of the freezer compressor drive belt again.

1) Loosen the tension pulley lock nut.

2) Turn the tension pulley adjust bolt to adjust the tension.

Note

- The standard deflection shown is the value obtained when the specified load is applied to the measurement point of the freezer compressor drive belt.

Standard: 98 N { 10 kg / 22 lb } Load

Caution

- Accurately adjust the tension as there is a possibility the service life of the belt may be shortened or belt squeal may be generated if the tension is not within the appropriate range.

- Use a sonic tension meter to verify accurate tension adjustment.

| When new |

Reused |

|

| Tension |

541 to 721 N { 55 to 74 kg / 122 to 162 lb } |

379 to 505 N { 39 to 51 kg / 85 to 114 lb } |

| Vibration frequency |

181 to 209 Hz |

152 to 175 Hz |

| Deflection |

5.3 to 6.7 mm { 0.209 to 0.264 in } |

6.5 to 8.1 mm { 0.256 to 0.319 in } |

| When new |

Reused |

|

| Tension |

541 to 721 N { 55 to 74 kg / 122 to 162 lb } |

379 to 505 N { 39 to 51 kg / 85 to 114 lb } |

| Vibration frequency |

150 to 173 Hz |

125 to 144 Hz |

| Deflection |

6.4 to 8.0 mm { 0.252 to 0.315 in } |

8.4 to 10.0 mm { 0.331 to 0.394 in } |

Legend

- Tension pulley adjust bolt

- Tension pulley lock nut

- Freezer compressor drive belt

- Measurement position 1

- Measurement position 2

3) Tighten the tension pulley lock nut to the specified torque.

Tightening torque: 41 N・m { 4.2 kgf・m / 30 lb・ft }