1. Maintenance precautions of restraint

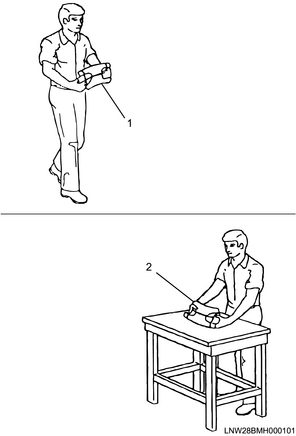

1. Handling an undeployed SRS airbag

Take extra care when handling and storing an undeployed SRS airbag. If the SRS airbag happens to deploy, material on the surface of the SRS airbag may be flung into the air due to the sudden generation of gas.

Warning

- When transporting an undeployed SRS airbag, make sure to face the trim cover of the SRS airbag outwards to minimize injury in case of an accidental deployment. Do not carry by the harness or connector.

- When storing an undeployed SRS airbag, or when leaving an undeployed SRS airbag on the work bench or other places, make sure to face the trim cover section of the SRS airbag upward to minimize injury in case of an accidental deployment.

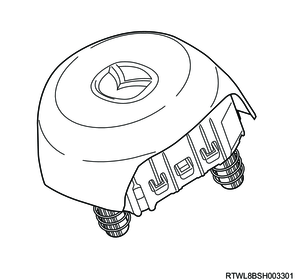

Driver airbag

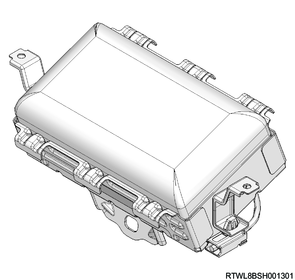

Passenger airbag

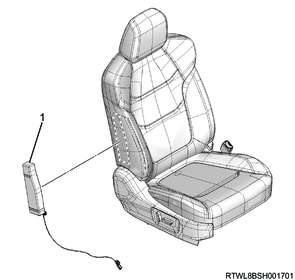

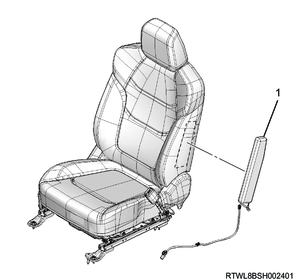

Side airbag

Legend

- Side airbag

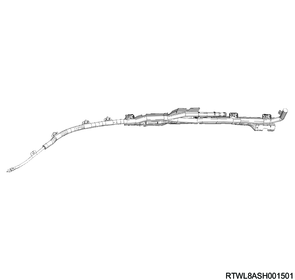

Curtain airbag

Far side airbag

Legend

- Far side airbag

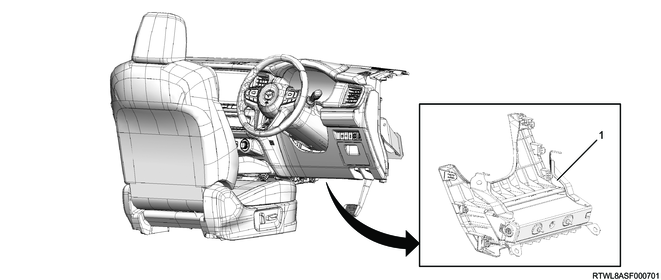

Driver knee airbag

Legend

- Driver knee airbag

Legend

- When transporting an undeployed SRS airbag, face the trim cover outward.

- When putting down an undeployed SRS airbag, make sure to face the trim cover upward.

2. Handling a deployed SRS airbag

The safety precautions must be followed.

Warning

- When handling a deployed SRS airbag, wear work gloves and protective goggles in order to protect your hands and eyes from irritants and heat that may be generated.

- Do not touch the metal surface of a deployed SRS airbag for approx. 30 minutes after deployment because it becomes extremely hot. Do not place a deployed SRS airbag near flammable objects. Not following this procedure may result in a fire or injury.

Caution

- If deployment has occurred, replace the SRS coil as well.

3. Handling an undeployed seat belt with pretensioner

Take extra care when handling and storing an undeployed seat belt with pretensioner. If the seat belt with pretensioner happens to deploy, material around the seat belt with pretensioner may be flung into the air due to the sudden generation of gas.

Warning

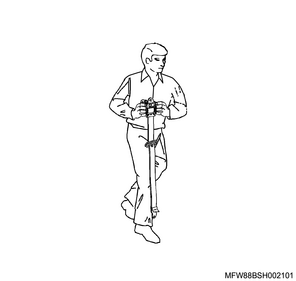

- When transporting an undeployed seat belt with pretensioner, make sure to face the gas generator section outwards to minimize injury in case of an accidental deployment. Do not carry by the belt section, harness, or connector.

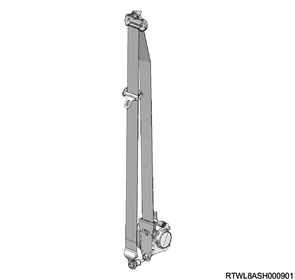

Seat belt with pretensioner

4. Handling a deployed seat belt with pretensioner

Warning

- When handling an activated seat belt with pretensioner, wear work gloves and protective goggles in order to protect your hands and eyes from irritants and heat that may be generated.

- Do not touch the metal surface of a deployed seat belt with pretensioner for approx. 30 minutes after deployment because it becomes extremely hot. Do not place a deployed seat belt with pretensioner near any flammable objects. Not following this procedure may result in a fire or injury.

Caution

- If deployment has occurred, replace the SRS coil as well.

5. Airbag sensor handling

Removal of sensors should be performed 15 seconds after the ignition switch is turned OFF.

The sensor should not be subjected to any impacts by being dropped, etc.

Replace the applicable airbag sensor, if it has been subjected to an impact such as from being dropped.

Without fail the airbag sensor must be replaced when the airbag has been deployed.

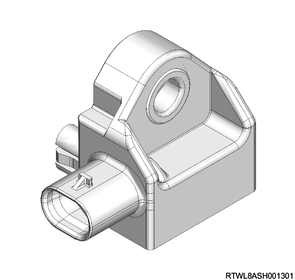

Front airbag sensor, floor side airbag sensor, and rear side airbag sensor

Door side airbag sensor

6. SRS maintenance precautions

Warning

- Before conducting maintenance of SRS components (SRS control unit, SRS airbag, seat belt with pretensioner, front airbag sensor, door side airbag sensor, floor side airbag sensor, rear side airbag sensor, harness, etc.) or in the area around these components, the SRS function must be temporarily deactivated by following the procedure. Not following the procedure may result in injury due to deployment of the SRS airbag, or unnecessary SRS airbag repairs.

7. Precautions for handling, installation, and diagnosis

Caution

- Do not expose the SRS airbag to temperatures exceeding 85°C (185°F).

- Do not reuse the SRS airbag, seat belt with pretensioner, SRS control unit, and airbag sensor, if they have been dropped for any reason.

- During the maintenance work, do not hit or shake the SRS control unit when handling it.

- If disconnecting connectors related to the SRS airbag, seat belt with pretensioner, SRS control unit, and airbag sensor, verify that they are completely connected during reassembly.

- When replacing the SRS control unit and the airbag sensor, check whether they are correctly installed to the installation surface again. Make sure there is no dust or other foreign material on the installation surface of the SRS control unit.

- Removal of the front airbag sensor, door side airbag sensor, floor side airbag sensor, and rear side airbag sensor should be performed 15 seconds or more after the ignition switch is turned OFF.

- When installing the SRS components, make sure to tighten them to the specified torque.

- Do not energize the system unless all SRS components are connected or requested to do so in the diagnosis. If the system is mistakenly energized, an unnecessary DTC may be set in the SRS control unit.

- Do not conduct a circuit diagnosis using an unspecified DMM.

- Before starting the diagnosis, perform the Diagnostic system check-SRS controls.

Whether the SRS airbag warning light operates normally can be checked by the Diagnostic system check-SRS controls. It also gives guidance regarding the appropriate diagnosis procedure used for diagnosing malfunctions in the system. Skipping these procedures may result in longer diagnosis time, incorrect diagnosis, or replacement of wrong parts.

8. Procedure to deactivate the SRS

1) Set the ignition switch to LOCK and remove the key.

Note

- For models with the passive entry and start system, turn the power mode OFF.

2) Remove the SRS fuse from the fuse relay box.

3) Disconnect the battery cable from the battery negative terminal.

Caution

- After turning OFF the ignition switch (power mode for models with passive entry and start system), do not disconnect the battery cable within 3 minutes.

- If the battery cable is disconnected within 3 minutes, the vehicle electronic control system may malfunction.

- If the battery cable is disconnected, perform the setting of the front door power window switch with AUTO UP/AUTO DOWN function after connecting the battery negative terminal.

- After disconnecting the battery cable, do not perform work for approximately 15 seconds.

9. Procedure to restore the SRS

Warning

- Never use SRS parts from other vehicles or models.

- Make sure to check the part numbers and use the SRS components intended for the target vehicle.

1) Set the ignition switch to LOCK and remove the key.

Note

- For models with the passive entry and start system, turn the power mode OFF.

2) Make sure that the connectors of the SRS components (SRS airbag, SRS control unit, seat belt with pretensioner, SRS coil, etc.) are fully connected.

3) Install the SRS fuse to the fuse relay box, and connect the battery cable to the negative terminal of the battery.

4) Turn the ignition switch ON and verify that the SRS airbag warning light turns OFF after illuminating for 6 seconds.

Caution

- If the SRS airbag warning light does not operate properly, perform Diagnostic system check - SRS controls.

5) Referring to the following, perform the setting of the front door power window switch with AUTO UP/AUTO DOWN function.

Refer to "9.Body, Cab, Accessories 9T.Glass, Windows, Mirrors front door power window switch setting".

10. Necessary repair and inspection after collision

If the SRS components are damaged, they must be replaced. If the installation location for SRS components is damaged, they must also be replaced. Do not use SRS components from other vehicles. Do not disassemble or repair the SRS components. Make sure to use new components. Check the part numbers of the SRS components to be used in order to verify that they are genuine products.

Warning

- Never use SRS components from other vehicles or models. Make sure to check the part numbers and use the SRS components intended for the target vehicle.

Caution

- After repairing or replacing parts damaged in the collision, in order for the SRS airbag and the seat belt with pretensioner to operate properly, it is necessary to inspect the SRS airbag, the seat belt with pretensioner, and the steering column. If the SRS control unit mounting bracket is damaged, replace it with a new one. If a collision has occurred, it is necessary to inspect the steering column regardless of whether the SRS airbag and the seat belt with pretensioner deployed.

11. Inspection of parts after a collision

- If the harness is damaged, make sure to replace it.

- If the connector or terminal is damaged, make sure to replace it.

- If the lead wire for parts such as the seat belt with pretensioner, etc., including the SRS airbag and SRS coil are damaged, replace all parts that have the lead wire.

12. Replacement and inspection of parts after collision accompanied by deployment

It is necessary to replace the following system components after a frontal collision accompanied by deployment. It is necessary to inspect the SRS coil for damage.

- SRS control unit

- SRS airbag

- Seat belt with pretensioner

- Combination switch (including SRS coil)

- Front airbag sensor

- Door side airbag sensor

- Floor side airbag sensor

- Rear side airbag sensor

Inspect the SRS coil harness and connector for burns, melting, or damage caused by excessive heat. Replace the combination switch if it is damaged.

13. SRS control unit and satellite sensor replacement guideline

The SRS control unit and front airbag sensor must be replaced after a collision accompanied by deployment. Perform the Diagnostic system check - SRS controls when the SRS airbag warning light is illuminated.

14. Inspection of components after collision with no deployment

After a collision, it is necessary to inspect whether the SRS function and the SRS components are normal even if the SRS airbag was not deployed. The components and details that should be inspected are as follows.

- Steering column: Inspect for distortion, bending, cracks, or other damage.

- Steering support bracket: Inspect for distortion, bending, cracks, or other damage.

- Instrument panel bracket: Inspect for distortion, bending, cracks, or other damage.

- Seat belt and installation location: Inspect for rattling, looseness when installed, or improper seat belt retraction.

- Seat and installation location: Rattling, looseness, bending, cracks, or other damage when installed

- Front airbag sensor: Inspect for improper installation or damage.

- Door side airbag sensor: Inspect for improper installation or damage.

- Floor side airbag sensor: Inspect for improper installation or damage.

- Rear side airbag sensor: Inspect for improper installation or damage.

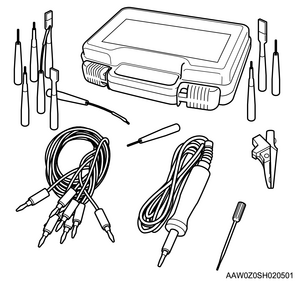

15. Tools to be used

Warning

- When performing maintenance of the SRS, in order to prevent the SRS airbag and the seat belt with pretensioner from activating, do not use inspection devices other than those specified in this manual. If inspection devices other than those specified in this manual are used, damage due to unnecessary activation of the SRS airbag or the seat belt with pretensioner may occur.

When measuring voltage and resistance, make sure to correctly use tools, such as a scan tool, SRS alternative load (5-8840-2856-0), adapter harness kit (5-8840-2857-0), SRS adapter for load tool (5-8840-2982-0, 5-8840-3257-0, 5-8840-3258-0, 5-8840-3269-0), connector test adapter kit (5-8840-2835-0), and digital multimeter [DMM] (5-8840-2392-0).

16. Digital multimeter (DMM)

Use a DMM (5-8840-2392-0) for diagnosing or repairing the SRS. Use of another DMM for diagnosing or repairing the SRS is not allowed.

Warning

- The SRS components may deploy if a different DMM is used.

17. SRS alternative load

An SRS alternative load is used as an auxiliary tool for diagnosis and as a safety device to prevent unnecessary deployment of the SRS airbag. The alternative load can be used during circuit inspection as a substitute for the SRS airbag and pretensioner load. By using the alternative load, it is possible to determine whether the cause of the system malfunction is the wiring or the SRS components. Use the alternative load only if required during the diagnosis procedure.

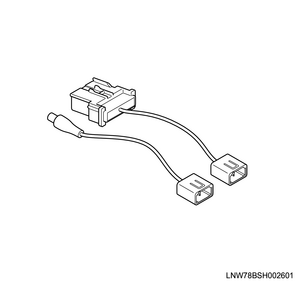

18. Adapter harness kit

The adapter harness kit (5-8840-2857-0) is used as an auxiliary tool for diagnosis and as a safety device to prevent unnecessary deployment of the SRS airbag. The adapter harness is used when connecting the SRS alternative load (5-8840-2856-0) to the SRS airbag, pretensioner, and each harness connector of the SRS coil. Because the adapter harness kit is equipped with 2 different types of adapter harnesses, use the appropriate adapter harness for the shape of the connector. Use the adapter harness only if directed to during the diagnosis procedure.

19. SRS adapter for load tool

The SRS adapter for load tool (5-8840-2982-0, 5-8840-3257-0, 5-8840-3258-0, 5-8840-3269-0) is used as an auxiliary tool for diagnosis and as a safety device to prevent unnecessary deployment of the SRS airbag. The SRS adapter for load tool is used when connecting the SRS alternative load (5-8840-2856-0) to the SRS airbag and each harness connector of the SRS coil. Use the appropriate adapter harness for the shape of the connector. Use the adapter harness only if directed to during the diagnosis procedure.

Driver side

Passenger side

Side airbag

Far side airbag

20. Connector test adapter kit

Use the connector test adapter kit (5-8840-2835-0) when the diagnostic procedure requires inspection or detailed checking using a terminal. Use the appropriate adapter to prevent the terminal from being damaged.