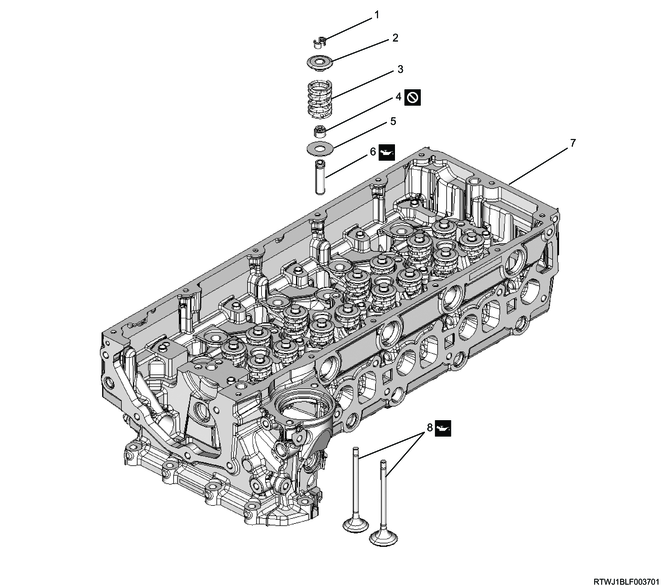

1. Component views

Cylinder head

Part name

- Split collar

- Spring upper seat

- Valve spring

- Valve stem oil seal

- Spring lower seat

- Valve guide

- Cylinder head

- Inlet valve and exhaust valve

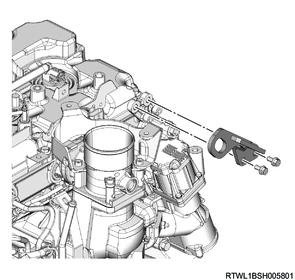

2. Heater pipe installation

1) Apply LOCTITE 262 to the heater pipe press-fit section.

2) Referring to the diagram, install the heater pipe to the cylinder head.

Caution

- Press-fit the heater pipe at the angle shown in the diagram until it makes full contact with the cylinder head.

Standard value

a: 30 °

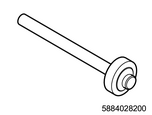

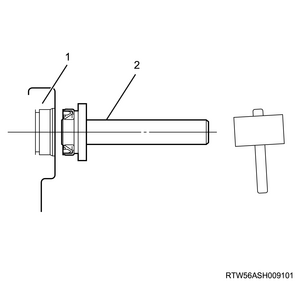

3. Oil seal installation

1) Install the oil seal to the cylinder head using the special tool.

Note

- Tap the oil seal into the injection pipe insertion surface evenly to prevent it from being tilted.

Caution

- Take care not to damage the lip section of the oil seal.

SST: 5-8840-2820-0 - Oil seal installer

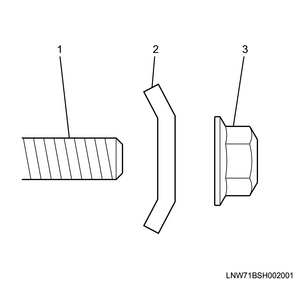

Legend

- Cylinder head

- 5-8840-2820-0

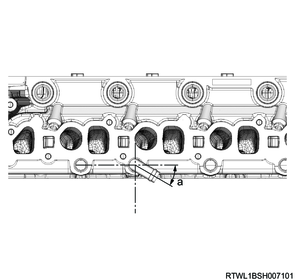

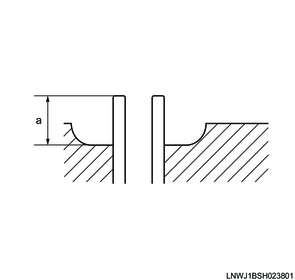

4. Valve guide installation

1) Tap in the valve guide from the top of the cylinder head to the standard depth using the special tool.

Caution

- When replacing the valve guide, replace as a set with the valve.

SST: 5-8840-2816-0 - valve guide remover and installer

Standard value

a: 12.5 to 12.7 mm { 0.492 to 0.500 in } Height from the cylinder head top surface to the valve guide end face

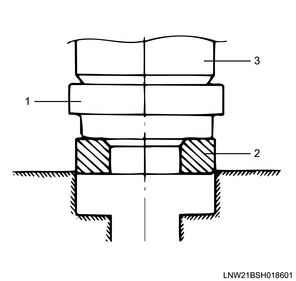

5. Valve seat insert installation

1) Put the dolly block on the valve seat insert.

Note

- Carefully place a dolly block having an outer diameter smaller than the valve seat insert on top of the valve seat insert.

2) Install the valve seat insert to the cylinder head using a press.

Note

- Gradually apply pressure to the dolly block and push in the valve seat insert.

Caution

- Do not apply excessive pressure with the press.

Legend

- Dolly block

- Valve seat insert

- Press

3) Add compound to the valve seat surface and gently tap the valve while turning it.

Caution

- Confirm that there is even contact around the entire circumference.

- After fitting, completely remove the compound.

6. Valve stem oil seal installation

1) Install a lower spring seat to the cylinder head.

2) Apply engine oil to the valve guide outer circumference.

3) Install the valve stem oil seal to the cylinder head using the special tool.

4) Inspect for the following.

- Is the valve stem oil seal correctly inserted?

- Is it slanted?

- Whether the garter spring is removed

SST: 5-8840-2882-0 - valve stem seal installer

7. Valve installation

1) Apply engine oil to the valve stems of the inlet valve and exhaust valve.

2) Install the inlet valve and the exhaust valve to the cylinder head.

8. Valve spring installation

1) Install the valve spring to the cylinder head.

2) Install the spring upper seat to the valve spring.

3) Install the split collar to the valve using the special tool.

SST: 5-8840-2865-0 - valve spring compressor adaptor

SST: 5-8840-2546-0 - valve spring compressor

Legend

- 5-8840-2865-0

- 5-8840-2546-0

4) Move the valve spring up and down to check that it moves smoothly.

5) Apply engine oil to the valve stem end cap and valve stem end.

6) Install the valve stem end cap to the valve stem.

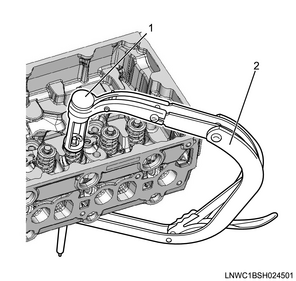

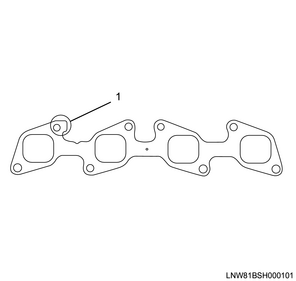

9. Exhaust manifold installation

1) Install the gasket to the cylinder head.

Note

- Face the gasket protruding portion to the cylinder head rear side.

Caution

- Do not reuse the gasket.

Legend

- Protrusion

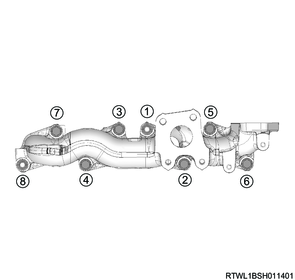

2) Referring to the diagram, temporarily tighten the exhaust manifold to the cylinder head.

Legend

- Stud bolt

- Washer

- Nut

3) Final tighten the exhaust manifold to the cylinder head in the order shown in the diagram.

Tightening torque: 52 N・m { 5.3 kgf・m / 38 lb・ft }

Caution

- Do not over-tighten since it will expand or contract due to the heat of the manifold.

4) Install the exhaust manifold heat protector to the exhaust manifold.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

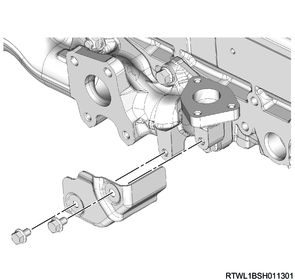

10. Inlet manifold installation

1) Temporarily tighten the inlet manifold and gasket to the cylinder head.

Caution

- Do not reuse the gasket.

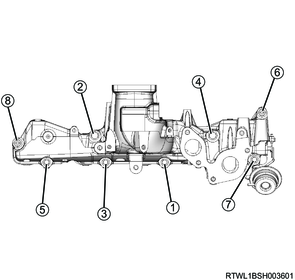

2) Final tighten the inlet manifold mounting bolts in the order shown in the diagram.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

3) Connect the vacuum hose to the inlet manifold.

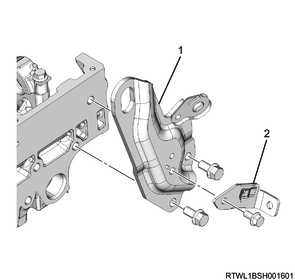

11. Front engine hanger installation

1) Install the front engine hanger to the cylinder head.

Tightening torque: 51 N・m { 5.2 kgf・m / 38 lb・ft }

2) Install the harness bracket to the front engine hanger.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

Legend

- Front engine hanger

- Harness bracket

12. Rear engine hanger bracket installation

1) Install the rear engine hanger bracket to the cylinder head.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

2) Install the special tool to the rear engine hanger bracket.

SST: 5-8840-2886-0 - rear engine hanger

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }