1. Rear axle shaft inspection

1. Visual inspection

1) Inspect the rear axle shaft for the following.

- Shaft cracks and damage

- Twist and crack of spline section

- Stepped wear

Note

- Replace if abnormal conditions are found as a result of component cleaning or inspection.

- Inspect by the dye penetrant method or magnetic flaw detection method, as necessary.

- Repair minor stepped wear with a pencil grinder or an oil stone.

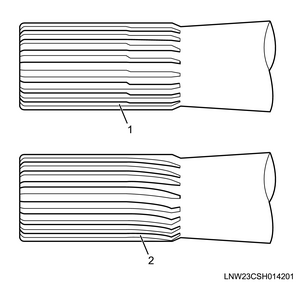

Legend

- Stepped wear

- Twisting

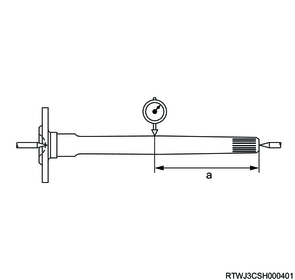

2. Rear axle shaft measurement

1) Measure the runout of the rear axle shaft at the location shown in the following diagram using a dial gauge.

Note

- Support the center of both ends of the rear axle shaft and slowly rotate the rear axle shaft to measure the runout.

Limit: 1.0 mm { 0.039 in }

Caution

- Never heat to repair any bent.

Measurement position

a: 350 mm { 13.78 in }

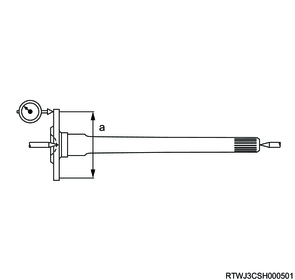

2) Measure the runout of the rear axle shaft flange section at the location shown in the following diagram using a dial gauge.

Note

- Support the center of both ends of the rear axle shaft and slowly rotate the rear axle shaft to measure the runout.

Limit: 0.08 mm { 0.003 in }

Measurement position

a: 160 mm { 6.30 in }