1. Camshaft inspection

1. Visual inspection

1) Inspect the camshaft journal and cam for the following.

- Damage

- Wear

Note

- Replace the camshaft if an abnormal condition is found.

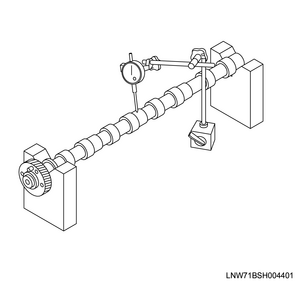

2. Camshaft runout measurement

1) Put the camshaft on the V-block.

2) Slowly turn the camshaft to measure the camshaft runout using a dial gauge.

Limit: 0.05 mm { 0.0020 in }

Note

- If the measured value exceeds the limit, replace the camshaft.

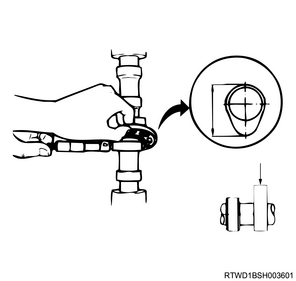

3. Cam lobe height measurement

1) Measure the height of the cam lobe using a micrometer.

Note

- If the measured value exceeds the limit, replace the camshaft.

| Inlet |

Standard value |

40.8 mm { 1.606 in } |

| Limit |

39.8 mm { 1.567 in } |

|

| Exhaust |

Standard value |

40.8 mm { 1.606 in } |

| Limit |

39.8 mm { 1.567 in } |

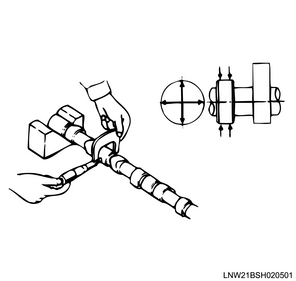

4. Camshaft journal measurement

1) Measure the diameter of the camshaft journal using a micrometer.

| Inlet |

Standard value |

29.909 to 29.930 mm { 1.17752 to 1.17834 in } |

| Limit |

29.809 mm { 1.17358 in } |

|

| Exhaust |

Standard value |

29.909 to 29.930 mm { 1.17752 to 1.17834 in } |

| Limit |

29.809 mm { 1.17358 in } |

|

| Uneven wear |

Limit |

0.05 mm { 0.0020 in } |

Note

- If the measured value exceeds the limit, replace the camshaft.

2) Measure the inner diameter of the camshaft bracket using a cylinder gauge.

3) Calculate the clearance from the camshaft bracket inner diameter and journal diameter measurements.

| Inlet |

Standard value |

0.070 to 0.112 mm { 0.00276 to 0.00441 in } |

| Limit |

0.15 mm { 0.0059 in } |

|

| Exhaust |

Standard value |

0.070 to 0.112 mm { 0.00276 to 0.00441 in } |

| Limit |

0.15 mm { 0.0059 in } |

Note

- Replace the camshaft or camshaft bracket if the measured value exceeds the limit.