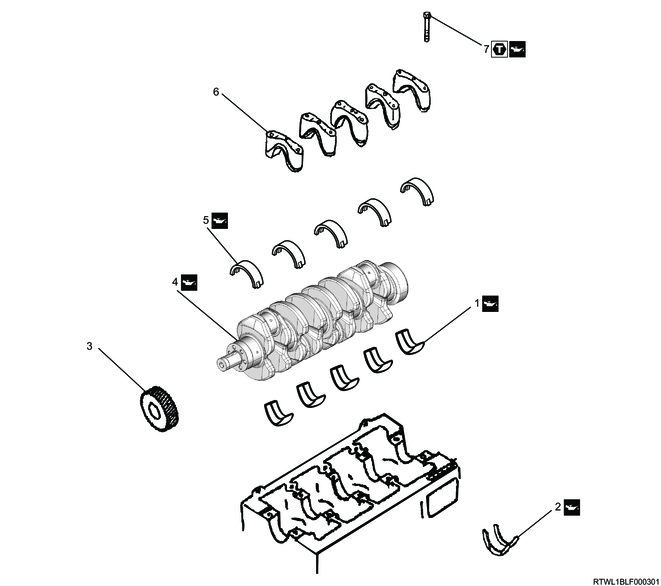

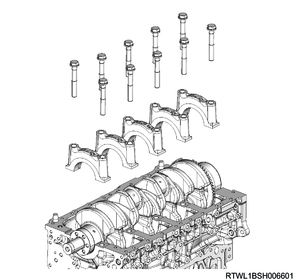

1. Component views

Crankshaft

Part name

- Upper crankshaft bearing

- Thrust bearing

- Crank gear

- Crankshaft

- Lower crankshaft bearing

- Bearing cap

- Bearing cap bolt

Tightening torque

7: 167 N・m { 17.0 kgf・m / 123 lb・ft }

2. Crankshaft installation

If replacing the crankshaft bearing, select the crankshaft bearing grade.

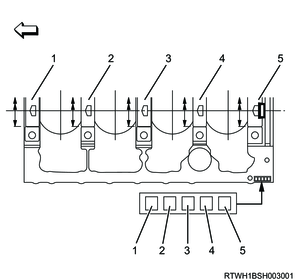

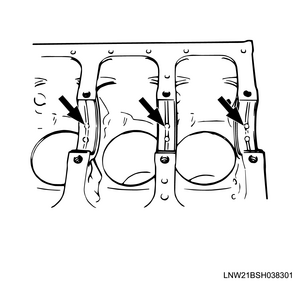

1) Check the cylinder block journal hole inner diameter grade.

Note

- Grade 1, 2, or 3 is marked on the rear right of the cylinder block.

Legend

- No. 1

- No. 2

- No. 3

- No. 4

- No. 5

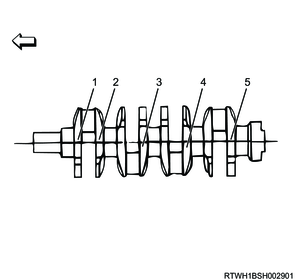

2) Check the crankshaft journal diameter grade.

Note

- The crankshaft journal grade marking is marked on each crankshaft journal.

Legend

- No. 1

- No. 2

- No. 3

- No. 4

- No. 5

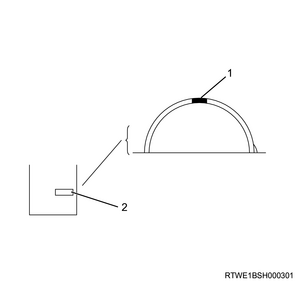

3) Check the crankshaft bearing lot number and size code.

Legend

- Lot No.

- Grade identification color

4) Select the crankshaft bearing based on the journal hole diameter grades of the crankshaft journal and cylinder block.

| Crankshaft bearing housing |

Crankshaft journal |

Crankshaft bearing size color |

||

| Grade mark |

Inner diameter |

Grade mark |

Outer diameter |

|

| 1 |

73.992 to 74.000 mm { 2.9131 to 2.9134 in } |

1 or - |

69.927 to 69.932 mm { 2.7530 to 2.7532 in } |

Yellow |

| 2 or -- |

69.922 to 69.927 mm { 2.7528 to 2.7530 in } |

|||

| 3 or --- |

69.917 to 69.922 mm { 2.7526 to 2.7528 in } |

Red |

||

| 2 |

73.983 to 73.991 mm { 2.9127 to 2.9130 in } |

1 or - |

69.927 to 69.932 mm { 2.7530 to 2.7532 in } |

Black |

| 2 or -- |

69.922 to 69.927 mm { 2.7528 to 2.7530 in } |

Blue |

||

| 3 or --- |

69.917 to 69.922 mm { 2.7526 to 2.7528 in } |

Yellow |

||

| 3 |

73.975 to 73.982 mm { 2.9124 to 2.9127 in } |

1 or - |

69.927 to 69.932 mm { 2.7530 to 2.7532 in } |

Green |

| 2 or -- |

69.922 to 69.927 mm { 2.7528 to 2.7530 in } |

Black |

||

| 3 or --- |

69.917 to 69.922 mm { 2.7526 to 2.7528 in } |

|||

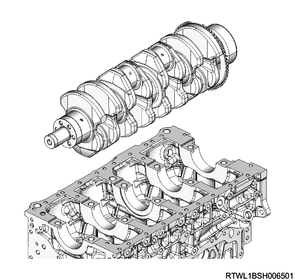

5) Install the crankshaft upper bearing to the cylinder block.

Note

- Check that the crankshaft upper bearing has oil holes and an oil groove.

Caution

- Do not confuse the difference of bearing shapes.

6) Apply engine oil to the sliding surface of the crankshaft upper bearing.

Caution

- Do not apply engine oil to the cylinder block installation surface and back surface of the bearing.

7) Thoroughly apply engine oil to the crankshaft journal section.

8) Install the crankshaft to the cylinder block.

Caution

- Prevent the crank angle sensor rotor from coming in contact with the cylinder block, etc., when installing the crankshaft.

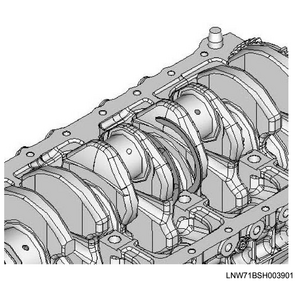

9) Thoroughly apply engine oil to the thrust bearing.

10) Install the thrust bearings to the front and rear sides of the cylinder block No. 3 journal.

Caution

- Install so that the oil groove of the thrust bearing touches the crankshaft.

11) Install the lower crankshaft bearing to the bearing cap.

12) Apply engine oil to the sliding surface of the lower crankshaft bearing.

Caution

- Do not apply engine oil to the bearing cap installation surface and back surface of the bearing.

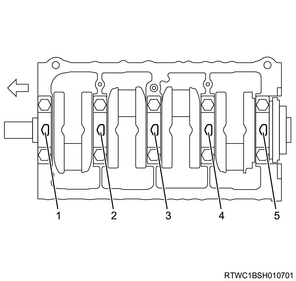

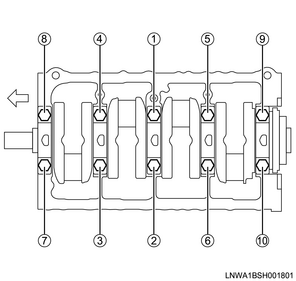

13) Install the bearing caps to the cylinder block in the order shown in the diagram.

Note

- Install so that the bearing cap front mark faces the front of the engine.

Legend

- No. 1

- No. 2

- No. 3

- No. 4

- No. 5

14) Apply engine oil to the threaded portions and seating surfaces of the bolts.

15) Final tighten the bearing cap bolts gradually to the cylinder block in the order shown in the diagram.

Tightening torque: 167 N・m { 17.0 kgf・m / 123 lb・ft }

16) Check that the crankshaft turns smoothly by rotating it manually after tightening each bearing cap location.

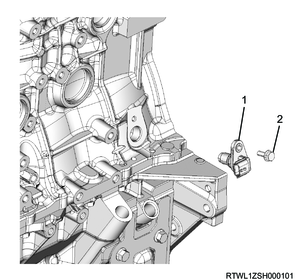

3. CKP sensor installation

1) Install the CKP sensor to the cylinder block.

Tightening torque: 5.0 N・m { 0.5 kgf・m / 44 lb・in }

Legend

- CKP sensor

- Bolt