1. Maintenance precautions of engine

1. ECM maintenance precautions

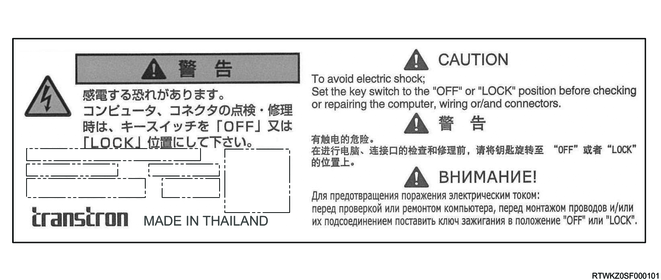

The exclamation mark warns of an electric shock hazard. To avoid shock and possible serious injury, do not touch the terminals. Before disconnecting the harness connector, be sure to either turn OFF the ignition switch or make sure to disconnect the battery cable.

The ECM has been designed to withstand the regular current consumption associated with vehicle operation. Make sure that the circuit does not overload. When testing for an open circuit or short circuit, do not ground or apply voltage to any of the ECM circuits unless instructed to do so. When performing these circuit tests, make sure to use a DMM. The ECM should remain connected to the ECM harness.

2. Commercial electronic equipment

Aftermarket or add-on electronic and vacuum equipment is defined as any device that is connected to the electrical or vacuum system of the vehicle after the vehicle has been shipped from the factory.

Be careful, as such accessories are not taken into particular consideration at the vehicle design stage.

Do not attach add-on vacuum equipment to this vehicle. Add-on electronic equipment can be connected to the vehicle electrical system only when the battery power supply and ground are provided.

Aftermarket electronic equipment may cause malfunctions in the electronic control system, even if the equipment is usually installed.

This includes devices not connected to the electrical system of the vehicle, such as mobile phones or radios.

Therefore, when diagnosing electrical system problems, first check whether such aftermarket electronic equipment is installed, and remove it from the vehicle if so. If the problem has not been resolved after removing the equipment, perform the diagnosis using the regular procedure.

Caution

- Make sure that both the power supply and ground of aftermarket electronic equipment are connected to a circuit that is not related to the circuits of the electronic control system.

3. Damage caused by electrostatic discharge

Because the electronic components used in the electronic control system are designed to operate at extremely low voltages, they can be easily damaged by electrostatic discharge, and some types of electronic components can be damaged by static electricity of 100 V or less, which cannot be felt by a person. (A voltage of 4,000 V is required for a person to be able to detect an electrostatic discharge.)

There are various ways a person can build up an electrostatic charge. The most common way to build up an electrostatic charge is through friction or induction.

An example of when a person builds an electrostatic charge by friction is when they slide across the seat of the vehicle.

A person wearing insulated shoes can build an electrostatic charge by induction if they momentarily touch the ground while standing near a highly charged object. A charge of the same polarity flows out, and with a highly opposing polarity, that person becomes charged. Because static electricity can be damaging, be careful when handling or testing electronic components.

Caution

- To prevent damage caused by static electricity discharge, do not touch the connector pins of the ECM or the electronic components soldered onto the circuit board of the ECM.

- To prevent damage caused by electrostatic discharges, do not open the packaging of a replacement part until preparations for installation of the replacement part are completed.

- To prevent damage caused by electrostatic discharge, connect the package to a properly working vehicle ground before removing the part from the package.

- To prevent damage caused by electrostatic discharge, touch a properly working ground before installing the part when handling it while sliding across the seat, while sitting down from a standing position, or while walking a certain distance.

4. Engine mechanical maintenance precautions

To prevent damage to the engine and to ensure the reliability of engine performance, be careful of the following points when performing engine maintenance.

Do not disconnect the battery cable or the wiring of the charging circuit while the engine is running. Also, do not open or close the battery relay.

When lifting or supporting the engine, do not position the jack directly under the oil pan. Use an engine pallet, wooden frame, etc., to support the engine with the engine foot or the flywheel housing.

When placing the engine on the ground, do not allow the oil pan to contact the ground directly. Use a wooden frame, etc., to support the engine with the engine foot or the flywheel housing. Because there is only a small gap between the oil pan and the oil pump strainer, take care not to damage the oil pan and oil pump strainer.

When the air intake/exhaust system has been removed, apply a seal to prevent foreign material from entering the cylinder. Entry of foreign material causes significant damage to the cylinder, etc.

Be sure to remove the battery negative terminal during maintenance. Be careful of causing a short circuit when inspecting parts that are energized.

When connecting the battery ground cable, pay attention to the battery poles. If the poles are reversely connected, the generator diode, etc. may be broken.

When disconnecting the harness, inspect the connectors and clips for damage and replace as necessary.

When connecting the harness, connect it to the same position and same routing as when disconnected.

When cleaning the engine with steam, take care not to allow steam or water to directly contact the battery or other electronic system components.

To protect and lubricate the sliding parts, apply an adequate amount of engine oil to the sliding sections.

When the valve-related parts, including the piston, piston rings, connecting rod, bearing, and injector, have been removed, organize them in order for storage.

When installing, use the same part and install in the same position as when removed.

Whenever disassembling, replace gaskets, oil seals, O-rings, etc., with new ones.

When using liquid gasket, completely remove any old liquid gasket, and after completely removing any oil, moisture, and foreign material, apply the specified liquid gasket and reassemble.

Apply a proper amount of the liquid gasket, avoiding excessive or insufficient application.

Excessive application can cause engine seizures, while insufficient application is a cause of oil or engine coolant leakage. Make sure to overlap the beginning and end of the application.

Assemble within the specified time after applying the liquid gasket. If the specified amount of time or more has passed, remove the old liquid gasket and reapply.

When assembling and installing, tighten to the specified tightening torque.

Do not use any sensor or injection system component that was dropped or hit forcefully as this may cause a failure.

When charging the battery using an external device, disconnect the battery ground cable.

5. Precautions for work particular to this engine

Including the inside of the injector, the holes and gaps that are to be used as the fuel paths for the fuel system have an extremely precise finish. Therefore, because there is a possibility of malfunction if foreign material enters, cap or cover after removing parts, etc., to prevent foreign material from entering.

6. Precautions for cooling system work

Warning

- Do not loosen the radiator cap or reserve tank cap when coolant is hot, as doing so may result in burns caused by the release of steam or hot water.

- When opening the radiator cap or reserve tank cap, place a thick cloth over the cap after the coolant has cooled, and turn it slowly to release the pressure before removing it.

7. Precautions for handling fuel-related parts

Including the inside of the injector, the holes and gaps that are the fuel paths for the fuel system have an extremely precise finish. For this reason, the sensitivity to foreign material is high, and because foreign material can lead to trouble on the road, take every precaution to prevent foreign material from getting inside.

Also, do not use fuel moisture removal agents because they can cause moisture to be absorbed into the diesel oil, which can cause rust.

8. Working procedure for parts related to fuel system

When the fuel pipe, injection pipe, injector, fuel supply pump, or fuel rail has been removed, quickly apply a seal to the fuel port.

Store the eyebolt and gasket in a clean parts box with a cover so that foreign material does not become attached to them.

Because fuel leakage may lead to fire, wipe off any leaked fuel after completing the work, and make sure to check for fuel leakage after starting the engine.

The fuel injector QR Code is specific to its fuel injector. Do not confuse the injector QR Code with other codes. Also, if a fuel injector is replaced, the Injector ID Code should be learned by the ECM.

9. Precautions when working on starting system

Poor meshing occurs if the gap between the pinion and ring gear is not appropriate.

Securely fix the front bracket to the engine when installing it.

When removing and installing the starter, make sure to disconnect the battery negative terminal before performing the work.

Securely tighten and insert the wiring. If there is looseness, the contact resistance becomes large, causing a hard start.

10. Precautions for starting system at start-up

Ensure that the battery is fully charged. An insufficient charge may cause hard starting.

After verifying that the engine starts, immediately release the ignition switch.

One continuous operation time is limited to 10 seconds. Restart the engine after the pinion is completely stopped.

If the starter does not stop rotating even if the ignition switch is turned OFF, turn the engine key switch OFF and remove the battery negative terminal immediately. In such cases, inspect wiring, switches, etc.

11. Generator handling

When handling the generator, pay attention to the following points.

If the battery poles are reversely connected, the diode of the generator will be broken.

Do not disconnect the battery terminal or the wiring of the charging circuit while the engine is running.

Make sure to connect each terminal wiring according to the terminal symbol.

Do not perform megger testing on semiconductor devices.

When inspecting the equipment, make sure to disconnect the battery negative terminal before performing work.

When charging from external equipment, such as for a quick charge, disconnect the battery negative terminal before performing the work.

Do not directly apply steam cleaners, water, etc.

Tighten to 12 N⋅m {1.27 kgf⋅m / 106 lb⋅ft} after wiring the B-terminal.

12. Emission control system

When assembling the EGR system, temporarily tighten and then final tighten so as not to apply unnecessary stress on the components.

13. Exhaust system

Because vibrations and looseness of the exhaust system can be caused by mispositioning of exhaust system components during assembly, temporarily tighten the bolts until all components are in position, and final tighten from the engine side working back to the rear pipe.

14. Lubrication system

Because lubrication system parts are precision components, take adequate precautions to prevent dirt or dust from entering when performing maintenance.

When disassembling the section where liquid gasket is used, completely scrape off the old liquid gasket, and apply the new liquid gasket after cleaning so that no oil, moisture, or foreign material is left.

Apply a proper amount of the liquid gasket, avoiding excessive or insufficient application. Be careful not to apply excessively, as this will cause seizures due to clogging of the oil gallery and oil jet, or insufficiently, as this will cause oil leaks.

Make sure to overlap the beginning and end of the application.

15. Boost system

The turbocharger is built with extreme precision and rotates at high speeds, and therefore cannot be disassembled. Replace the turbocharger as an assembly if abnormal conditions such as bent fins, a bent housing, or scratches are found.

Take measures to prevent foreign material from entering the turbine housing, compressor housing, or oil inlet and outlet while performing maintenance work.

After maintenance of the turbocharger, inject approximately 1.0 cc {0.00026 US gal / 0.00022 Imp. gal} of clean engine oil into the oil feed port, and rotate the turbine shaft before installing the oil pipe.

When installing the turbocharger, clean the duct and hose connection surface, and replace the hose with a new one if there is breakage or expansion.

Grabbing the actuator rod to lift the turbocharger will deform it, causing a malfunction. Always hold the turbocharger body without grabbing the rod.

16. Preheating system

Be careful because the glow plug can be damaged if it is over-tightened.