1. Timing chain installation

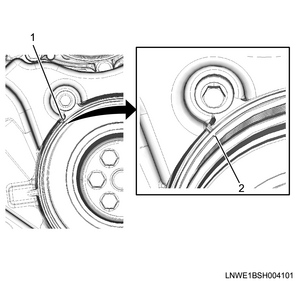

1) Rotate the crankshaft in the forward direction (clockwise) to align the No. 1 cylinder piston to compression top dead center.

Legend

- Top dead center alignment mark on the gear case cover side

- Crankshaft pulley side top dead center alignment mark

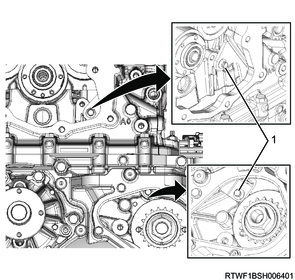

2) Install the timing chain guide to the cylinder head and cylinder block.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

Legend

- Timing chain guide bolt

3) Insert the timing chain tension lever into the gap between the timing gear case and the cylinder block.

4) Align the timing chain with the supply pump sprocket.

5) Install the sprocket and timing chain as a set to idle gear D.

Tightening torque: 8.0 N・m { 0.8 kgf・m / 71 lb・in }

6) Apply engine oil to the threaded portion and seating surface of the idle gear D shaft bolt.

7) Install the idle gear D shaft bolt and sleeve to idle gear D and sprocket.

Tightening torque: 59 N・m { 6.0 kgf・m / 44 lb・ft }

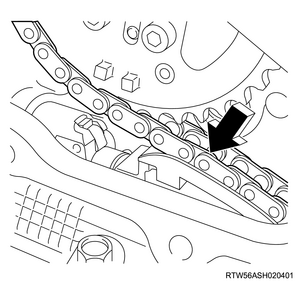

8) Align the 2 timing alignment marks at the location shown in the diagram.

Legend

- Timing chain

- Timing mark

- Blue link

- Yellow link

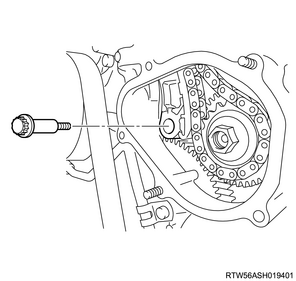

9) Install the timing chain lever pivot to the timing chain tension lever.

Tightening torque: 27 N・m { 2.8 kgf・m / 20 lb・ft }

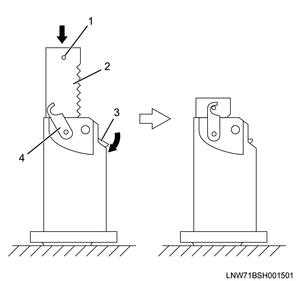

10) Push down the timing chain tensioner latch and insert the plunger.

Note

- Install the hook to the pin while pressing the plunger.

Legend

- Pin

- Plunger

- Latch

- Hook

11) Install the timing chain tensioner and gasket to the cylinder head.

Caution

- Do not reuse the gasket.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

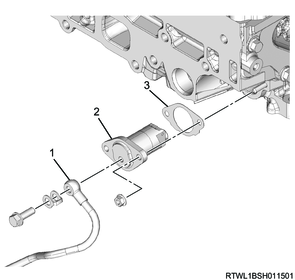

12) Install the oil feed pipe to the timing chain tensioner.

Caution

- Do not reuse the gasket.

Tightening torque: 14.7 N・m { 1.5 kgf・m / 130 lb・in }

Legend

- Oil feed pipe

- Timing chain tensioner

- Gasket

13) Lightly press the area indicated by the arrow in the diagram to disconnect the hook from the pin.

Note

- The hook of the tensioner opens and the plunger pushes the tension lever to pull the chain.

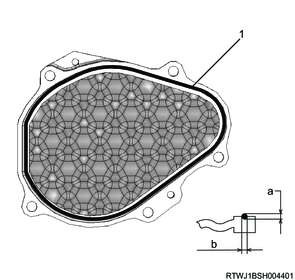

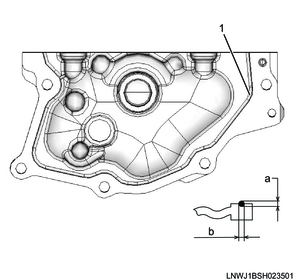

2. Timing chain lower cover installation

1) Referring to the diagram, apply ThreeBond 1207C or equivalent to the timing chain lower cover.

Legend

- Liquid gasket

Standard value

a: 2.0 to 2.5 mm { 0.079 to 0.098 in } Bead height

b: 2.0 to 2.5 mm { 0.079 to 0.098 in } Bead width

2) Install the timing chain lower cover to the gear case cover.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

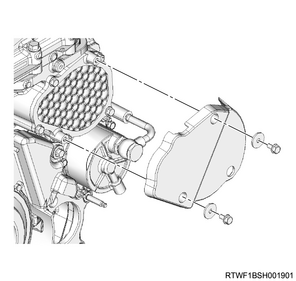

3) Install the noise cover to the timing chain lower cover.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

3. Timing chain upper cover installation

1) Referring to the diagram, apply ThreeBond 1207C or equivalent to the timing chain upper cover.

Caution

- Install the timing chain cover within 5 minutes of applying the liquid gasket.

Legend

- Liquid gasket

Standard value

a: 1.0 to 1.5 mm { 0.039 to 0.059 in } Bead height

b: 2.0 to 2.5 mm { 0.079 to 0.098 in } Bead width

2) Install the timing chain upper cover to the cylinder head.

Caution

- Wipe off any excess liquid gasket.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

3) Connect the connector to the CMP sensor.

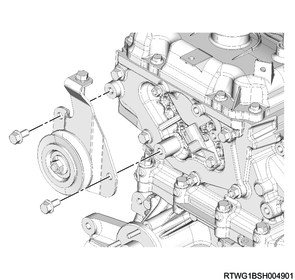

4. Tension pulley installation

1) Install the tension pulley to the cylinder head.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

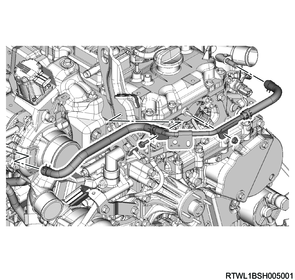

5. Water pipe installation

1) Install the water pipe to the following parts.

- Thermostat

- Cylinder head

- Turbocharger

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in } Bolt, nut

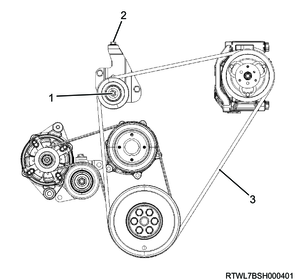

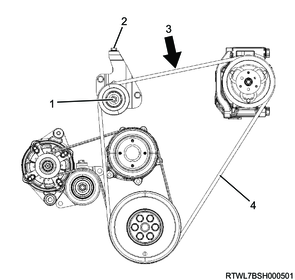

6. A/C compressor drive belt installation

1) Install the A/C compressor drive belt to the following parts.

- Tension pulley

- A/C compressor

- Crankshaft pulley

Legend

- Lock nut

- Adjust bolt

- A/C compressor drive belt

7. Cylinder head cover installation

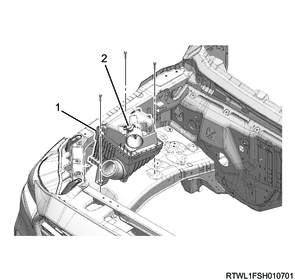

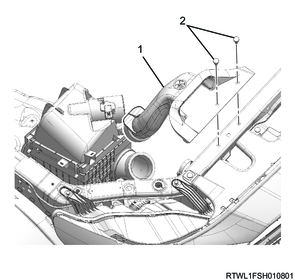

8. Air cleaner installation

1) Install the air cleaner to the vehicle.

Tightening torque: 20 N・m { 2.0 kgf・m / 15 lb・ft }

2) Connect the connector to the MAF and IAT sensor.

Legend

- Air cleaner

- MAF and IAT sensor

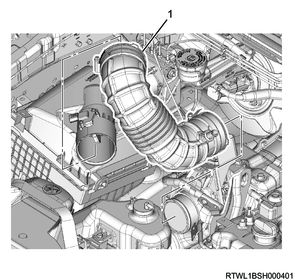

9. Air duct installation

1) Align the air duct with the air cleaner and turbocharger.

Legend

- Air duct

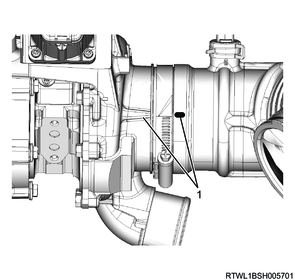

2) Referring to the diagram, align the alignment mark positions and connect the air duct to the turbocharger.

Tightening torque: 4.0 N・m { 0.4 kgf・m / 35 lb・in }

Legend

- Alignment mark

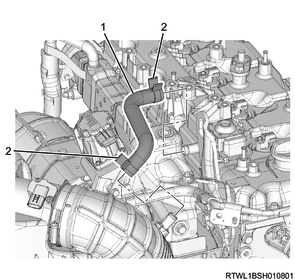

3) Install the PCV hose to the cylinder head cover and air duct.

Caution

- Align the marks on the pipe side and hose side.

Legend

- PCV hose

- Clamp

4) Install the intake air duct to the air cleaner and radiator core support.

Legend

- Intake air duct

- Clip

10. Underguard installation

11. Preliminary and post procedures

1. Post procedures

1) Lower the vehicle.

2) Connect the battery cable to the battery negative terminal.

3) Referring to the following, perform the setting of the front door power window switch with AUTO UP/AUTO DOWN function.

Refer to "9.Body, Cab, Accessories 9T.Glass, Windows, Mirrors front door power window switch setting".

4) Close the engine hood.

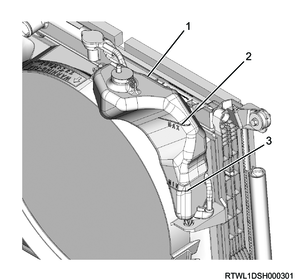

12. Coolant filling

1) Fill with engine coolant up to the radiator filler neck.

Note

- Fill with engine coolant of the specified concentration to the brim of the radiator cap inlet.

Caution

- Fill slowly to prevent air from entering the system.

2) While pressing the radiator upper hose manually several times to bleed the air from the hose, fill the radiator with engine coolant.

Note

- Fill with engine coolant up to the brim of the radiator cap inlet with the amount the engine coolant lowers.

Caution

- Repeat the operation until the coolant level no longer drops.

3) Add engine coolant up to the MAX line of the radiator reserve tank.

Legend

- Radiator reserve tank

- MAX line

- MIN line

4) Install the radiator cap to the radiator.

5) Start and idle the engine.

Caution

- Idle the engine for 5 minutes or more.

6) Stop the engine.

7) Remove the radiator cap from the radiator.

Warning

- Do not loosen the radiator cap or reserve tank cap when coolant is hot, as doing so may result in burns caused by the release of steam or hot water.

- When opening the radiator cap, cover the cap with a thick cloth once the engine coolant has cooled and slowly turn to release pressure.

8) Fill with engine coolant up to the radiator filler neck.

Note

- If the engine coolant is excessively low, inspect for engine coolant leakage from the cooling system.

9) Install the radiator cap to the radiator.

10) Start the engine.

11) Increase the engine speed to around 2000 rpm and run the engine for 10 minutes once the engine coolant temperature gauge reaches the center.

12) With the engine running, check that the thermostat valve is open.

Note

- Touch the radiator upper hose, and confirm that it has become warm.

- If it has not become warm, go back to Step 11.

Caution

- Do not try determining it by using only an engine coolant temperature gauge.

13) Idle the engine for 5 minutes.

14) Stop the engine.

15) Remove the radiator cap from the radiator.

Warning

- Do not loosen the radiator cap or reserve tank cap when coolant is hot, as doing so may result in burns caused by the release of steam or hot water.

- When opening the radiator cap, cover the cap with a thick cloth once the engine coolant has cooled and slowly turn to release pressure.

16) Fill with engine coolant up to the radiator filler neck.

Note

- Fill with engine coolant of the specified concentration to the brim of the radiator cap inlet.

17) Add engine coolant up to the MAX line of the radiator reserve tank.

18) Install the radiator cap to the radiator.

19) Repeat steps 10 to 18 until the coolant level no longer lowers.

Caution

- If the level of the radiator reserve tank has fallen the next morning, add up to the MAX line.

13. A/C compressor drive belt adjustment

When installing a new belt, initial stretching of the belt occurs.

In addition, when reusing the belt, the belt needs to be fitted to the pulley groove.

After fitting the A/C compressor drive belt, adjust the tension of the A/C compressor drive belt again.

1) Loosen the tension pulley lock nut.

2) Turn the tension pulley adjust bolt to adjust the tension.

Note

- The standard deflection shown is the value obtained when the specified load is applied to the measurement point of the A/C compressor drive belt.

98 N { 10.0 kg / 22 lb } Load

Caution

- Accurately adjust the tension as there is a possibility the service life of the belt may be shortened or belt squeal may be generated if the tension is not within the appropriate range.

- Use a sonic tension meter to verify accurate tension adjustment.

| Adjustment conditions |

Deflection |

Vibration frequency |

| When new |

12.5 to 16.5 mm { 0.49 to 0.65 in } |

92 to 112 Hz |

| Reused |

16.5 to 19.1 mm { 0.65 to 0.75 in } |

79 to 91 Hz |

Legend

- Lock nut

- Adjust bolt

- Measurement point

- A/C compressor drive belt

3) Tighten the tension pulley lock nut to the specified torque.

Tightening torque: 51 N・m { 5.2 kgf・m / 38 lb・ft }