1. Maintenance precautions of heating, ventilation air conditioning

Caution

- Make sure to keep the work area clean at all times.

- Always wear protective goggles when performing work on the A/C system.

- Be careful of carbon monoxide emissions or discharge of refrigerant gas when starting the engine in a closed area or a poorly ventilated garage.

- When replacing or repairing the A/C system, always disconnect the battery negative terminal and discharge the refrigerant.

- Use a recovery device when draining the refrigerant.

- Be careful of humidity and dust.

- When removing refrigerant piping or parts, immediately plug or cap the ends, and do not remove until reconnecting or installing the piping or parts.

- For the A/C piping and hose connection, use 2 open-end wrenches to prevent piping twisting and damage, and turn the flare nut using one open-end wrench while supporting the flare union using the other open-end wrench.

- Apply new compressor oil to the O-ring before connecting a hose or a pipe.

- The procedure for removing or replacing parts that require refrigerant to be discharged from the A/C system is to first discharge refrigerant from the A/C system, then remove and replace malfunctioning parts, and finally to evacuate and refill with the specified amount of refrigerant.

1. Repairing refrigerant leaks

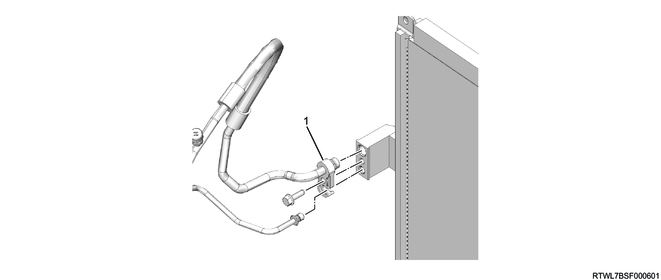

When connecting the block joint section refrigerant pipe, fit the convex section of the joint section firmly into the connection hole of the unit side and secure it with a bolt.

Legend

- Block joint

Apply compressor oil to the O-ring before connecting.

Caution

- Do not reuse the O-ring.

- As the type of compressor oil to be used will vary depending on the compressor type, always use compressor oil that is compatible with the compressor in question.

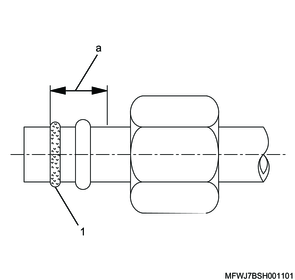

Legend

- O-ring

Legend

a. Oil application area

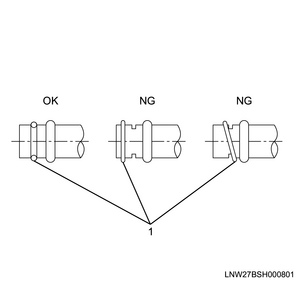

Securely insert the O-ring into the groove of the refrigerant pipe.

Legend

- O-ring

2. Leakage at the refrigerant piping joint

1) Inspect for leakage from the refrigerant piping connecting parts.

Note

- If there is leakage, discharge the refrigerant from the A/C system.

2) Inspect the O-ring and replace as necessary.

Caution

- Do not reuse the O-ring.

- Always connect after applying compressor oil to the replaced O-rings.

3) Evacuate, then fill refrigerant and check the A/C system.

3. Leakage from the hose

If the refrigerant is leaking from the inlet or outlet hose of the compressor, replace the entire hose.

Caution

- Do not cut the hoses or connect other hoses.

1) Identify the location of the refrigerant leak.

Note

- If there is leakage, discharge the refrigerant from the A/C system.

2) Disconnect the hose and connect a new hose to the compressor.

Caution

- When disconnecting the hose, cap or put a cover on the connections.

3) Tighten the hose connection parts to the specified torque.

4) Evacuate, then fill refrigerant and check the A/C system.

4. Leakage from the compressor

1) If there is compressor oil leakage from the compressor shaft seal or shell, replace the compressor.

5. Handling the refrigerant

Inside the A/C system, a chemical refrigerant circulates.

It requires special handling procedures in order to prevent accidents caused by mishandling.

1) When installing/removing or replacing the A/C cycle parts, be sure to wear goggles, and that the refrigerant piping and unit connections are caped and covered.

Caution

- If the refrigerant comes into contact with the human body, wash with fresh water and seek medical treatment.

- Perform work in a well-ventilated area.

- Do not attempt to weld or steam clean the A/C piping or the unit installed to the vehicle.

2) If refrigerant needs to be transferred from a big container to small one, consider expansion of the refrigerant, and be sure to prepare a sufficiently large container.

Caution

- Do not fill the container full with the refrigerant.

- Store the refrigerant container at temperatures of 40°C {104°F} or less.