1. Backup light switch inspection

1) Inspect the backup light switch using a DMM.

Note

- It is normal if there is continuity between both terminals when the push rod is pressed, and if there is no continuity when released.

2. Neutral switch inspection

1) Inspect the neutral switch using a DMM.

Note

- It is normal if there is continuity between both terminals when the push rod is released, and if there is no continuity when pressed.

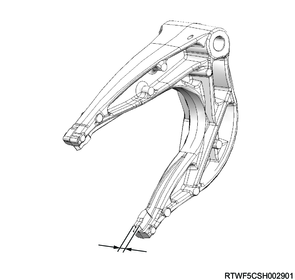

3. Shift rod inspection

1) Inspect the following shift rods for bending, wear, or damage.

- Reverse and 5th - 6th shift rod

- 1st - 2nd and 3rd - 4th shift rod

Note

- Inspect each part of the shift mechanism. Repair minor wear, bending and stepped wear.

- If significant, replace.

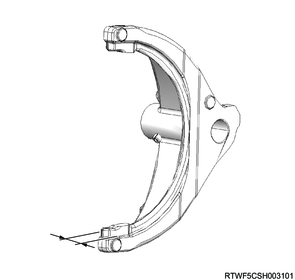

4. Shift arm inspection

1) Inspect the following shift arms.

- 1st - 2nd shift arm

- 3rd - 4th shift arm

- 5th - 6th shift arm

- Reverse shift arm

Note

- If excessive wear or damage is found during inspection, replace parts as necessary.

2) Measure the thickness of the shift arm ends using a micrometer.

Note

- Replace the shift arm if the measured value exceeds the limit.

| Standard value |

7.65 to 7.85 mm { 0.3012 to 0.3091 in } |

| Limit |

6.90 mm { 0.2717 in } |

| Standard value |

7.65 to 7.85 mm { 0.3012 to 0.3091 in } |

| Limit |

6.90 mm { 0.2717 in } |

1st - 2nd shift arm and reverse shift arm

| Standard value |

7.65 to 7.85 mm { 0.3012 to 0.3091 in } |

| Limit |

6.90 mm { 0.2717 in } |

3rd - 4th shift arm

| Standard value |

7.65 to 7.85 mm { 0.3012 to 0.3091 in } |

| Limit |

6.90 mm { 0.2717 in } |

5th - 6th shift arm