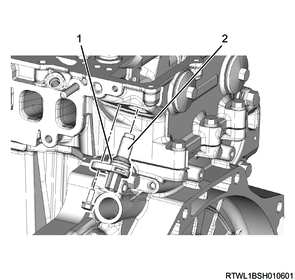

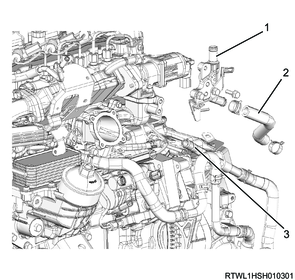

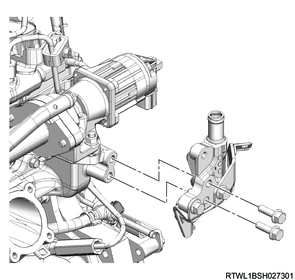

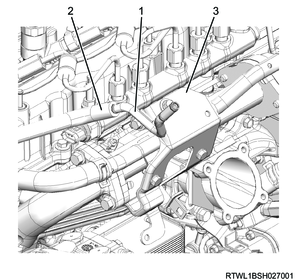

1. CMP sensor installation

1) Apply soapy water to the O-ring.

2) Install the CMP sensor to the cylinder head.

Tightening torque: 5.0 N・m { 0.51 kgf・m / 44.3 lb・in }

Legend

- O-ring

- CMP sensor

3) Connect the connector to the CMP sensor.

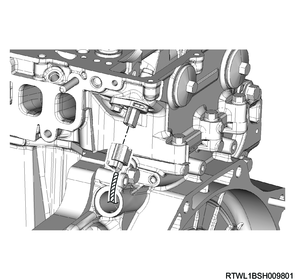

4) Install the fuel pipe bracket to the cylinder head.

Note

- Install so that the fuel pipe bracket detent makes contact with the cylinder head indentation.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

Legend

- Detent

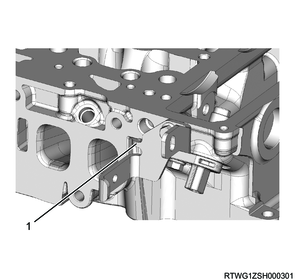

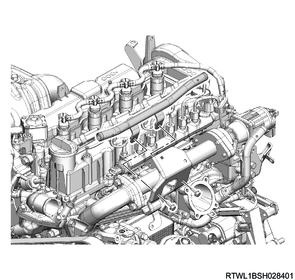

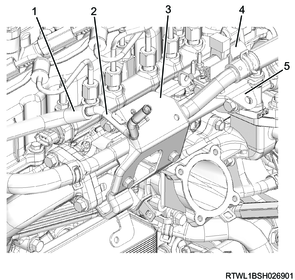

2. Fuel feed pipe installation

1) Install the fuel feed pipe to the fuel supply pump and common rail (fuel rail).

Caution

- Do not reuse the fuel feed pipe.

Tightening torque: 35 N・m { 3.6 kgf・m / 26 lb・ft }

Legend

- Fuel feed pipe

2) Install the clip to the fuel feed pipe.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

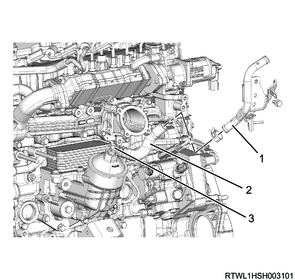

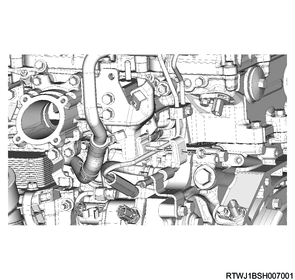

3. Fuel leak-off pipe installation

1) Install the fuel leak-off pipe to the common rail (fuel rail) and flywheel housing.

Tightening torque: 20.2 N・m { 2.1 kgf・m / 15 lb・ft } Common rail (fuel rail) side

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft } Flywheel housing side

Legend

- Fuel leak-off pipe

2) Connect the fuel leak-off hose to the fuel leak-off pipe.

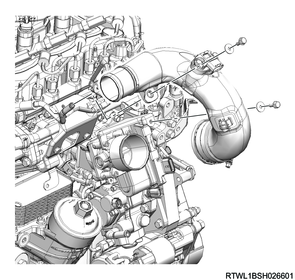

4. EGR cooler water hose connect

1. Euro4 specifications

1) Install EGR cooler water pipe A to the inlet cover.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

2) Connect the EGR cooler water hose to EGR cooler water pipe A.

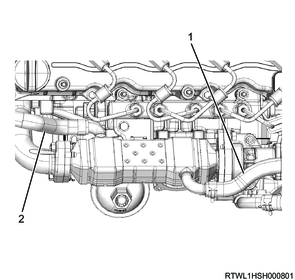

Manual transmission models

Legend

- EGR cooler water pipe A

- EGR cooler water hose

- EGR cooler water pipe B

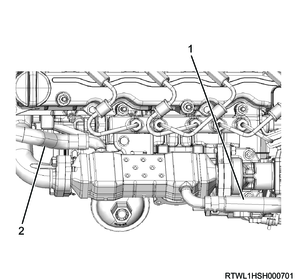

Automatic transmission models

Legend

- EGR cooler water pipe A

- EGR cooler water hose

- Water pipe

3) Connect the EGR cooler water return hose to the EGR cooler.

4) Connect the EGR cooler water feed hose to the EGR cooler.

Manual transmission models

Legend

- EGR cooler water return hose

- EGR cooler water feed hose

Automatic transmission models

Legend

- EGR cooler water return hose

- EGR cooler water feed hose

5. Water pipe installation

1. Except for Euro4 specifications

1) Install the water pipe to the inlet cover.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

Manual transmission models

Automatic transmission models

2) Install the pipe clip to the water pipe.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

3) Install the water pipe to the air duct bracket.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

4) Install the water hose to the water pipe.

Manual transmission models

Automatic transmission models

5) Install the vacuum pipe to the air duct bracket.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in }

6) Connect the vacuum hose to the vacuum pipe.

Euro2 specifications

Legend

- Vacuum pipe

- Vacuum hose

- Bracket

Except for Euro2 specifications

Legend

- Vacuum hose

- Vacuum pipe

- Bracket

- Relief valve control solenoid valve

- Relief valve control solenoid valve bracket

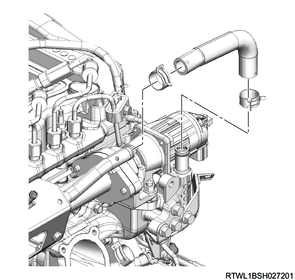

6. Oil level gauge guide tube installation

1) Apply engine oil to the O-ring.

2) Install the oil level gauge guide tube to the crankcase.

Tightening torque: 25 N・m { 2.5 kgf・m / 18 lb・ft }

3) Install the oil level gauge to the oil level gauge guide tube.

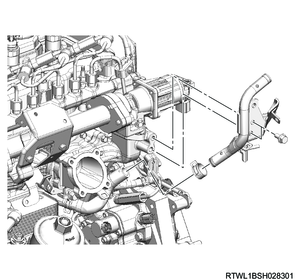

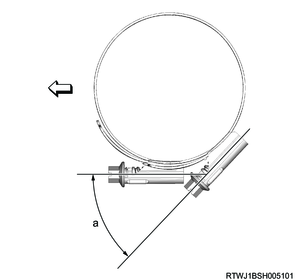

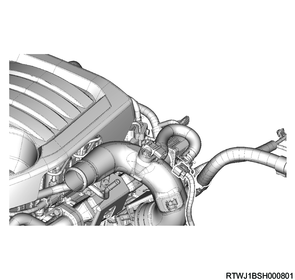

7. Intake air duct installation

1) Install the intake duct to the intake throttle valve.

Tightening torque: 10.0 N・m { 1.0 kgf・m / 89 lb・in } Bolt

Tightening torque: 4.0 N・m { 0.4 kgf・m / 35 lb・in } Clamp (Intake throttle side)

Clamp installation direction

Standard value

a: 45 °

2) Connect the connector to the boost pressure and CAC temperature sensor.

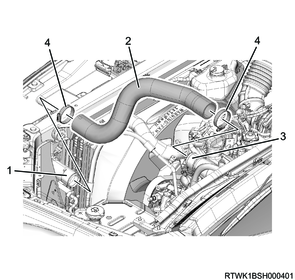

8. Air intake hose installation

1) Install the air intake hose to the intake air duct and intercooler.

Caution

- Align the marks on the pipe side and hose side.

Tightening torque: 5.0 N・m { 0.5 kgf・m / 44 lb・in }

Legend

- Intercooler

- Air intake hose

- Intake air duct

- Clamp

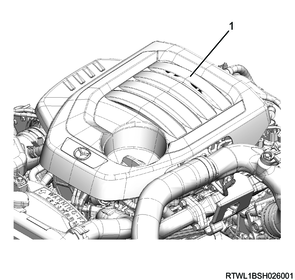

9. Engine cover installation

1) Install the engine cover to the engine.

Legend

- Engine cover

10. Underguard installation

11. Engine oil filling

1) Replenish the engine with the engine oil.

2) Check the tightening of the oil pan drain plug.

Tightening torque: 83 N・m { 8.5 kgf・m / 61 lb・ft }

12. Preliminary and post procedures

1. Post procedures

1) Lower the vehicle.

2) Connect the battery cable to the battery negative terminal.

3) Referring to the following, perform the setting of the front door power window switch with AUTO UP/AUTO DOWN function.

Refer to "9.Body, Cab, Accessories 9T.Glass, Windows, Mirrors front door power window switch setting".

4) Close the engine hood.

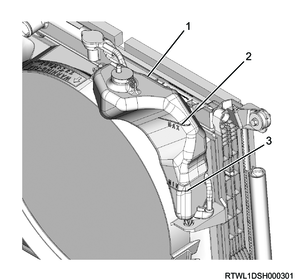

13. Coolant filling

1) Fill with engine coolant up to the radiator filler neck.

Note

- Fill with engine coolant of the specified concentration to the brim of the radiator cap inlet.

Caution

- Fill slowly to prevent air from entering the system.

2) While pressing the radiator upper hose manually several times to bleed the air from the hose, fill the radiator with engine coolant.

Note

- Fill with engine coolant up to the brim of the radiator cap inlet with the amount the engine coolant lowers.

Caution

- Repeat the operation until the coolant level no longer drops.

3) Add engine coolant up to the MAX line of the radiator reserve tank.

Legend

- Radiator reserve tank

- MAX line

- MIN line

4) Install the radiator cap to the radiator.

5) Start and idle the engine.

Caution

- Idle the engine for 5 minutes or more.

6) Stop the engine.

7) Remove the radiator cap from the radiator.

Warning

- Do not loosen the radiator cap or reserve tank cap when coolant is hot, as doing so may result in burns caused by the release of steam or hot water.

- When opening the radiator cap, cover the cap with a thick cloth once the engine coolant has cooled and slowly turn to release pressure.

8) Fill with engine coolant up to the radiator filler neck.

Note

- If the engine coolant is excessively low, inspect for engine coolant leakage from the cooling system.

9) Install the radiator cap to the radiator.

10) Start the engine.

11) Increase the engine speed to around 2000 rpm and run the engine for 10 minutes once the engine coolant temperature gauge reaches the center.

12) With the engine running, check that the thermostat valve is open.

Note

- Touch the radiator upper hose, and confirm that it has become warm.

- If it has not become warm, go back to Step 11.

Caution

- Do not try determining it by using only an engine coolant temperature gauge.

13) Idle the engine for 5 minutes.

14) Stop the engine.

15) Remove the radiator cap from the radiator.

Warning

- Do not loosen the radiator cap or reserve tank cap when coolant is hot, as doing so may result in burns caused by the release of steam or hot water.

- When opening the radiator cap, cover the cap with a thick cloth once the engine coolant has cooled and slowly turn to release pressure.

16) Fill with engine coolant up to the radiator filler neck.

Note

- Fill with engine coolant of the specified concentration to the brim of the radiator cap inlet.

17) Add engine coolant up to the MAX line of the radiator reserve tank.

18) Install the radiator cap to the radiator.

19) Repeat steps 10 to 18 until the coolant level no longer lowers.

Caution

- If the level of the radiator reserve tank has fallen the next morning, add up to the MAX line.