1. Maintenance precautions of security and locks control

Warning

- Individuals with implanted cardiac pacemakers or implanted defibrillators should keep a distance of at least 22 cm from the external antenna, center in-vehicle antenna, and engine start/stop button (immobilizer coil). The radio waves emitted from each antenna of the passive entry and start system may influence the operation of the devices.

1. Precautions for handling electronic key

The electronic key is comprised of precise electronic components. Failure of electronic components may influence the passive entry and start system. When handing an electronic key, pay attention to the following.

- Do not leave it in the vehicle.

- Do not leave it in a place with direct sunlight, high temperature, or high humidity.

- Do not drop it or put heavy objects, etc., on it.

- Do not wet or wash it using an ultrasonic washing machine, etc.

- Do not disassemble it unnecessarily except when replacing the battery.

- Do not expose it to metals or cover it.

- Do not place it near magnetized objects or electro-medical equipment.

- Do not remove the authentication label.

- Do not use a modified electronic key.

Caution

- Before performing repairs on the passive entry and start system, it is necessary to be aware of the following points.

- Even when the electronic key is within the operating range of passive entry and start system functions (within approximately 80 cm of the outside handle), locking/unlocking of the doors may not be possible depending on the height of the key (too low to the ground, etc.).

- Do not expose it to metallic objects or cover it.

- Locking/unlocking of the doors may not be possible if the electronic key is too close to the doors or windows.

- If the electronic key stays on the instrument panel or in the glove box, etc., the warning buzzer may sound depending on the state of electromagnetic waves.

- If the electronic key is outside the vehicle and the power mode is turned OFF, switching to other modes is not possible. (Switching to other modes is possible if the electronic key is returned to within the receiver range.)

2. Safety precautions

The exhaust gas is highly poisonous and can lead to fainting and/or death. When performing an inspection with the engine ON in a closed location such as a garage, make sure there is adequate ventilation in the area to ensure no exhaust gas is breathed in. Before inspecting with a scan tool, firmly engage the parking brake. Also, use chock blocks to stabilize the vehicle.

3. Using circuit test tools

Unless instructed in the diagnostic procedure, do not use a test lamp. When a probe connector is required in a diagnostic procedure, use connector test adapter kit (5-8840-2835-0).

4. Commercial electronic equipment

Aftermarket electronic equipment refers to commercially available electronic equipment installed to the vehicle after it has been shipped from the factory. Be careful because they are not taken into particular consideration at the vehicle design stage.

Aftermarket electronic equipment may cause malfunctions in the electronic control system, even if the equipment is properly installed. Aftermarket electronic equipment includes devices not connected to the electronic control system of the vehicle, such as mobile phones or radios. Therefore, when diagnosing electrical system problems, first check whether such aftermarket electronic equipment is installed. Remove from the vehicle if installed. If the problem has not been resolved after removing the equipment, perform the diagnosis using the regular procedure.

Caution

- Make sure that both the power supply and ground of aftermarket electronic equipment are connected to a circuit that is not related to the circuits of the electronic control system.

5. Damage caused by static electricity

Because the electronic components used in the electronic control system are designed to operate at extremely low voltages, they can easily be damaged by electrostatic discharge, and some types of electronic components can be damaged by an electrostatic charge of 100 V or less, which cannot be felt by humans. (A voltage of 4,000 V is required for a person to be able to detect a static electricity.)

There are various ways that a person can build up an electrostatic charge. The most common way to build up an electrostatic charge is through friction or induction. As an example of an electrostatic charge by friction, it can be built when a person slide across the seat of the vehicle. A person wearing insulated shoes can build an electrostatic charge by induction if they momentarily touch the ground while standing near a highly charged object. A charge of the same polarity flows out, and with a highly opposing polarity, that person becomes charged. Because static electricity causes damage, be extremely careful when handling or testing electronic components.

Caution

- To prevent damage caused by static electricity, do not touch the connector pins of the wireless access module or the electronic components soldered onto the circuit board of the wireless access module.

- To prevent damage caused by static electricity, do not open the packaging of a replacement part until the preparations for installation of the part are completed.

- To prevent damage caused by static electricity, connect the package to a properly working vehicle ground before removing the part from the package.

- To prevent damage caused by static electricity, touch a properly working ground before installing the part in such cases as when handling the part while sliding across a seat, when sitting down from a standing position, or while walking a certain distance.

6. Tools to be used

When measuring the voltage and resistance, make sure to correctly use the tools, such as the scan tool, connector test adapter kit (5-8840-2835-0), and digital multimeter [DMM] (5-8840-0285-3).

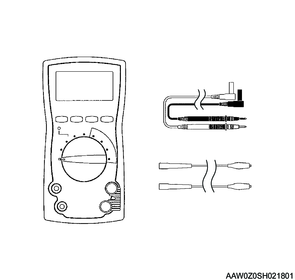

7. Digital multimeter (DMM)

Use the specified DMM (5-8840-0285-3) for diagnosing or repairing the wireless access module. Use of the other DMMs for diagnosing or repairing the wireless access module is not allowed.

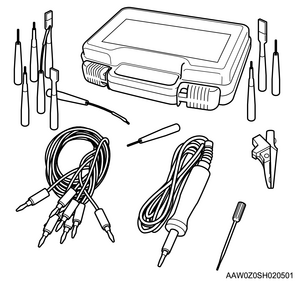

8. Connector test adapter kit

Use the connector test adapter kit (5-8840-2835-0) when the diagnostic procedure requires inspection or detailed checking using a terminal. Use the appropriate adapter to prevent the terminal from being damaged.