1. Starter motor inspection

1. Visual inspection

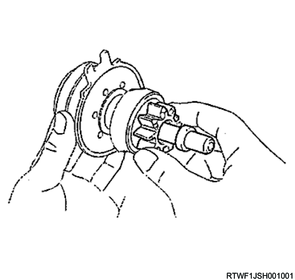

1) Inspect the overrunning clutch gear teeth for the following.

- Excessive wear

- Damage

2) Turn the overrunning clutch pinion by hand and inspect for the following.

- Smooth rotation when turning in the clockwise direction

- The pinion locks when turned in the counter-clockwise direction.

Note

- Replace the overrunning clutch if a malfunction is found.

3) Inspect the internal gear for the following.

- Abnormal wear

- Damage

Note

- Replace the internal gear if an abnormal condition is found.

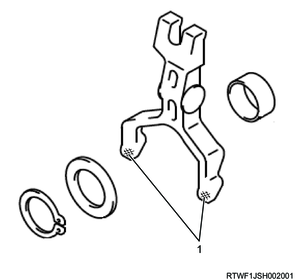

4) Inspect the shift lever for the following.

- Abnormal wear

- Damage

Note

- Replace the shift lever if an abnormal condition is found.

Legend

- Sliding section

2. Armature inspection

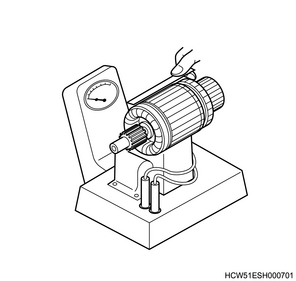

1) Make sure there is no short circuit inside the armature coil using a growler tester.

2) Measure the runout of the commutator using a dial gauge.

Note

- Replace the armature if the measured value exceeds the limit.

Limit: 0.05 mm { 0.00197 in }

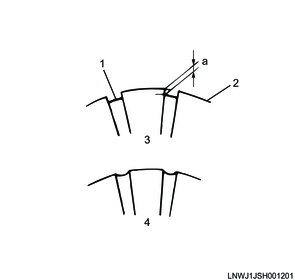

3) Measure the depth of the mica section of the commutator.

Note

- If the mica segment depth is less than or equal to the standard value but more than the limit, the commutator can be reground.

- If the mica segment depth is less than the limit, the armature must be replaced.

Limit: 0.2 mm { 0.008 in }

Legend

- Mica segment

- Commutator section

- Normal

- Defective

Legend

a. Mica segment depth

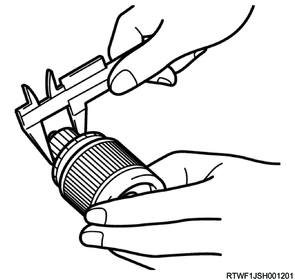

4) Measure the outer diameter of the commutator using a vernier caliper.

Standard: 29.0 mm { 1.142 in }

Limit: 28.0 mm { 1.102 in }

Note

- Replace the armature if the measured value exceeds the limit.

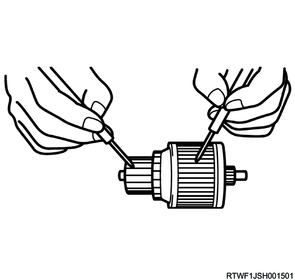

5) Apply the probe to the commutator section and armature core, and inspect for poor insulation at the armature using a DMM.

Note

- Replace the armature if a malfunction is found.

6) Apply the probe to the 2 commutator sections, and inspect for continuity at the armature using a DMM.

Note

- There should be continuity between all segments of the commutator.

- If there is no continuity, replace the armature.

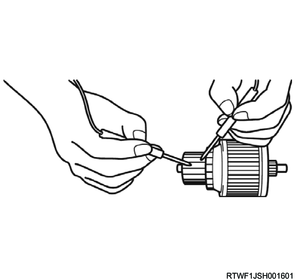

3. Brush inspection

1) Measure the brush length of the 4 brushes using a vernier caliper.

Caution

- If the length of any of the brushes is shorter than the limit, replace all brushes.

- If there is excessive wear on a negative brush, replace the entire brush holder.

- If there is excessive wear on a positive brush, replace the entire yoke.

Limit: 7 mm { 0.28 in }

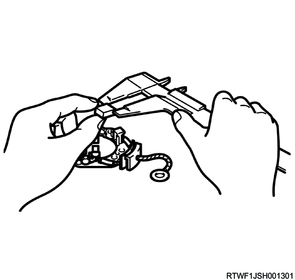

2) Apply the probe to the holder plate and positive brush holder, and inspect for poor insulation at the brush holder using a DMM.