1. Cylinder block inspection

1. Cleaning

1) Carefully remove the liquid gasket, water stains, or foreign material on the top surface of the cylinder block.

Caution

- Do not damage the cylinder block.

2. Visual inspection

1) Inspect the cylinder block for the following.

- Cracking

- Damage

Note

- Perform a dye penetrant check as necessary.

- Replace the cylinder block if cracking or damage is found.

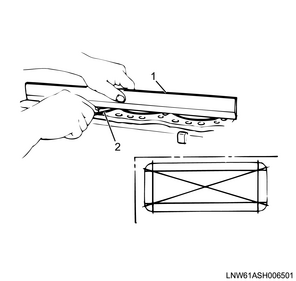

3. Cylinder block deformation measurement

1) Remove the dowel pin from the cylinder block.

2) Measure the 4 sides and 2 locations in a diagonal line of the cylinder block top surface using a simple straight ruler and feeler gauge.

Note

- If the measured value exceeds the limit, replace the cylinder block.

Caution

- Do not polish the cylinder block top surface.

Limit: 0.075 mm { 0.0030 in }

Legend

- Simple straight ruler

- Feeler gauge

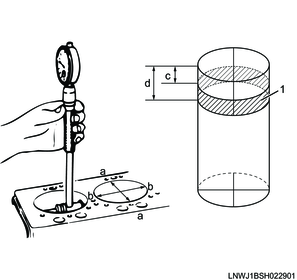

4. Cylinder block inner diameter measurement

1) Measure the most worn section of the cylinder bore in the measurement area using a cylinder gauge.

Note

- Measure the entire circumference in the measurement area, and read the value for the most worn section.

Legend

- Measurement area

Legend

a. Thrust direction

b. Radial direction

Measurement position

c: 10 mm { 0.39 in }

d: 15 mm { 0.59 in }

2) Calculate the average based on the measured values in the thrust direction and radial direction.

Standard: 80.000 to 80.030 mm { 3.1496 to 3.1508 in }

Limit: 80.055 mm { 3.1518 in }

Note

- If the measured value exceeds the limit, replace the cylinder block.