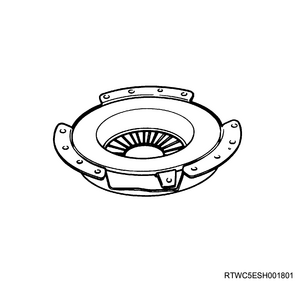

1. Clutch pressure plate inspection

1) Visually inspect the clutch pressure plate friction surface for excessive wear and heat cracks.

Note

- If excessive wear or deep heat cracks are found, replace the clutch pressure plate.

2) Inspect deformation.

Note

- Measure the plane surface of the clutch pressure plate friction surface in 4 directions using a straight gauge and feeler gauge.

- Replace the clutch pressure plate if any of the measured values exceed the limit.

Limit: 0.3 mm { 0.012 in }

3) Inspect the clutch cover.

Note

- Visually inspect the entire clutch cover for excessive wear, cracks and other damage.

- Replace the clutch cover if any malfunction is found.

4) Visually inspect the pressure plate regarding the clutch disc for the following.

- Worn flexible surface

- Scratches

- Crack

- Wear

- Rivet looseness

- Worn ring

Note

- Polish out any slight scratches.

- Replace the clutch pressure plate as an assembly if heavy scratches are found.

2. Clutch pressure plate measurement

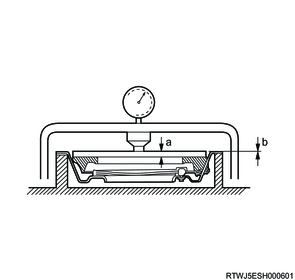

1. Clutch set load inspection

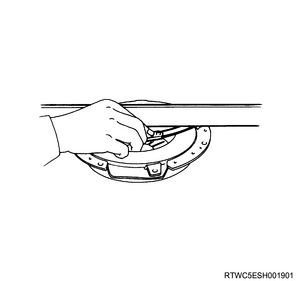

1) Invert the clutch pressure plate.

2) Place the metal sheet on top of the pressure plate.

7.7 mm { 0.303 in } Metal sheet thickness (Dual mass flywheel specifications)

7.4 mm { 0.291 in } Metal sheet thickness (Except dual mass flywheel specifications)

Note

- Compress the clutch pressure plate until it is the specified value.

0 mm { 0 in } Specified value

3) Measure the load using a pressure gauge.

Standard: 6,860 N { 700 kg / 1,542 lb } RZ4E

Standard: 8,140 N { 830 kg / 1,830 lb } 4JJ3

Dimensions

a: 7.7 mm { 0.303 in } Metal sheet thickness (Dual mass flywheel specifications)

a: 7.4 mm { 0.291 in } Metal sheet thickness (Except dual mass flywheel specifications)

b: 0 mm { 0 in } Specified value

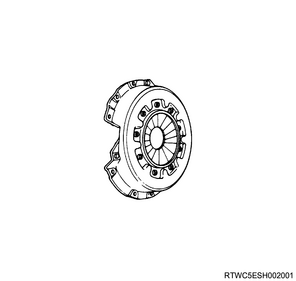

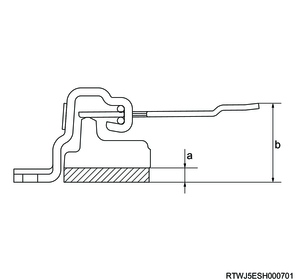

2. Diaphragm spring finger depth inspection

1) Place a new clutch disc or spacer under the pressure plate.

2) Completely compress the pressure plate and diaphragm spring.

Note

- Compress the pressure plate with a bench press from the top or by tightening with a fixing bolt.

3) Tighten the fixing bolt.

Caution

- The preload on the diaphragm spring finger should be the following value.

49 to 98 N { 5.0 to 10.0 kg / 11 to 22 lb } Preload (Release direction)

4) Measure the spring depth from the base to the spring end using a vernier caliper.

Note

- If the measured value exceeds the standard value, replace the clutch pressure plate.

Standard: 44 to 46 mm { 1.73 to 1.81 in }

Dimensions

a: 7.7 mm { 0.303 in } Spacer thickness (Dual mass flywheel specifications)

a: 7.4 mm { 0.291 in } Spacer thickness (Except dual mass flywheel specifications)

b: 44 to 46 mm { 1.73 to 1.81 in } From the base to the spring end

3. Clutch disc inspection

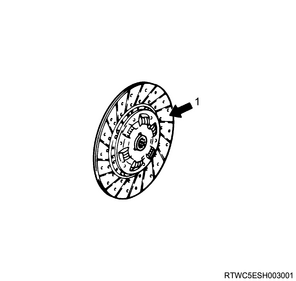

1. Clutch disc inspection (Except dual mass flywheel specifications)

1) Inspect the torsion spring for looseness, damage or fatigue.

Note

- Replace the clutch disc if any malfunction is found.

- Torsion spring

2) Inspect the facing surface for cracking, hardening, and grease adherence.

Note

- Clean or replace if any abnormal condition is found.

- Facing surface

3) Inspect that the clutch disc moves smoothly on the input shaft spline of the transmission.

Note

- If there is any minor interference on the gear shaft spline, remove it using an oil stone.

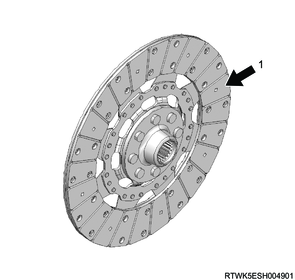

2. Clutch disc inspection (Dual mass flywheel specifications)

1) Inspect the facing surface for cracking, hardening, and grease adherence.

Note

- Clean or replace if any abnormal condition is found.

- Facing surface

2) Inspect that the clutch disc moves smoothly on the input shaft spline of the transmission.

Note

- If there is any minor interference on the gear shaft spline, remove it using an oil stone.

4. Clutch disc measurement

1. Clutch disc spline play inspection

1) Install the clutch disc to the input shaft.

2) Align the surface gauge to the outer circumference of the clutch disc.

3) Measure the play using a surface gauge.

Note

- Slowly turn the clutch disc counterclockwise to measure the play of the spline.

- If the measured value exceeds the limit, replace the clutch disc.

Standard: 0.5 mm { 0.020 in }

Limit: 1.0 mm { 0.039 in }

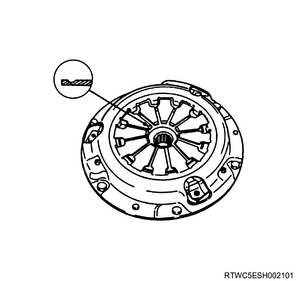

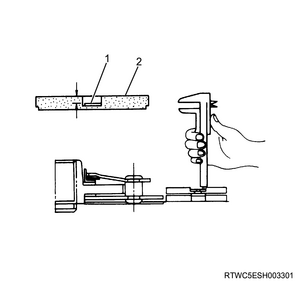

2. Facing rivet depth inspection

1) Measure the depth using a depth gauge.

Note

- Measure the rivet depth from the rivet head facing surface.

- Make sure to measure the rivet head depth from both surfaces of the clutch disc.

- If the measured value exceeds the limit, replace the clutch disc.

Standard: 1.15 to 1.75 mm { 0.045 to 0.069 in } Flywheel side

Standard: 1.35 to 1.95 mm { 0.053 to 0.077 in } Pressure plate side

Limit: 0.2 mm { 0.008 in }

Legend

- Rivet head

- Facing surface