|

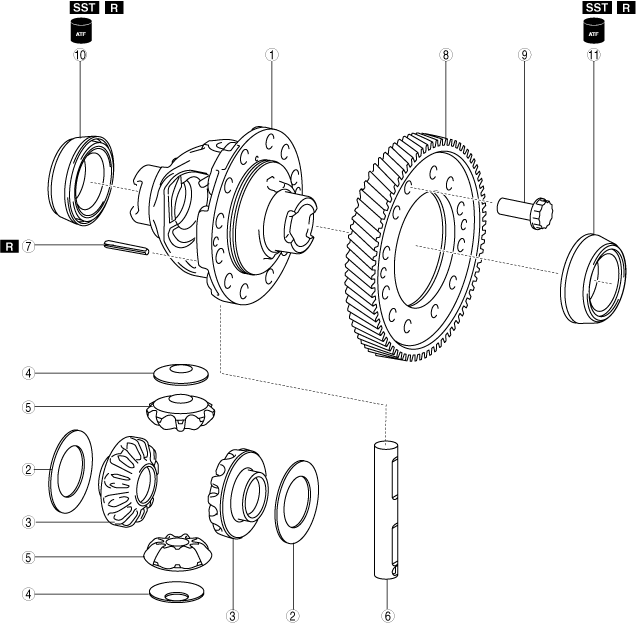

RING GEAR AND DIFFERENTIAL ASSEMBLY

id051700664100

Structural View

bgw2za00000124

|

|

1

|

Differential gear case

|

|

2

|

Thrust washer (selection)

|

|

3

|

Side gear

|

|

4

|

Thrust washer

|

|

5

|

Pinion gear

|

|

6

|

Pinion shaft

|

|

7

|

Roll pin

|

|

8

|

Ring gear

|

|

9

|

12 bolts (M13×1.0 bolt, length approx. 26.2 mm {1.03 in})

|

|

10

|

Tapered roller bearing (converter housing side)

(inner diameter approx. 55 mm {2.2 in}, inner race width approx. 23 mm {0.91 in})

|

|

11

|

Tapered roller bearing (transaxle case side)

(inner diameter approx. 55 mm {2.2 in}, inner race width approx. 20 mm {0.79 in})

|

Assembly Procedure

1. Assemble the thrust washers to the side gears.

azzjjw00001535

|

azzjjw00001536

|

2. Assemble the side gears which have the thrust washers assembled to them.

bgw3ja00000477

|

bgw3ja00000478

|

3. Assemble the thrust washers to the pinion gears.

azzjjw00001539

|

azzjjw00001540

|

4. Assemble the pinion gears which have the thrust washers assembled to them using the following procedure:

bgw3ja00000479

|

bgw3ja00000480

|

bgw3ja00000481

|

5. Assemble the pinion shaft.

bgw3ja00000482

|

bgw3ja00000483

|

6. Assemble a new roll pin to the position shown in the figure using a pin punch.

bgw2za00000127

|

bgw3ja00000485

|

7. Assemble the ring gear using the following procedure:

bgw3ja00000486

|

|

1

|

Ring gear

|

|

2

|

12 bolts (M13×1.0 bolt, length approx. 26.2 mm {1.03 in})

|

bgw3ja00000487

|

bgw3ja00000488

|

bgw3ja00000489

|

bgw3ja00000490

|

bgw3ja00000491

|

bgw3ja00000492

|

8. Assemble the tapered roller bearing (converter housing side) using the following procedure:

bgw2za00000128

|

bgw2za00000129

|

9. Assemble the tapered roller bearing (transaxle case side) using the following procedure:

bgw2za00000130

|

bgw2za00000131

|

10. Perform the differential backlash measurement/adjustment. (See DIFFERENTIAL BACKLASH MEASUREMENT/ADJUSTMENT.)